Subframe structure

A sub-frame and frame technology, which is applied to the substructure, vehicle components, jet propulsion devices, etc., can solve the problems of small mass, the area that cannot be vibrated and the partition area is enlarged, and the thickness and diameter of the circular plates 3a and 3b are increased. The effect of reducing the resonance frequency, improving the anti-vibration effect, and increasing the vibration isolation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

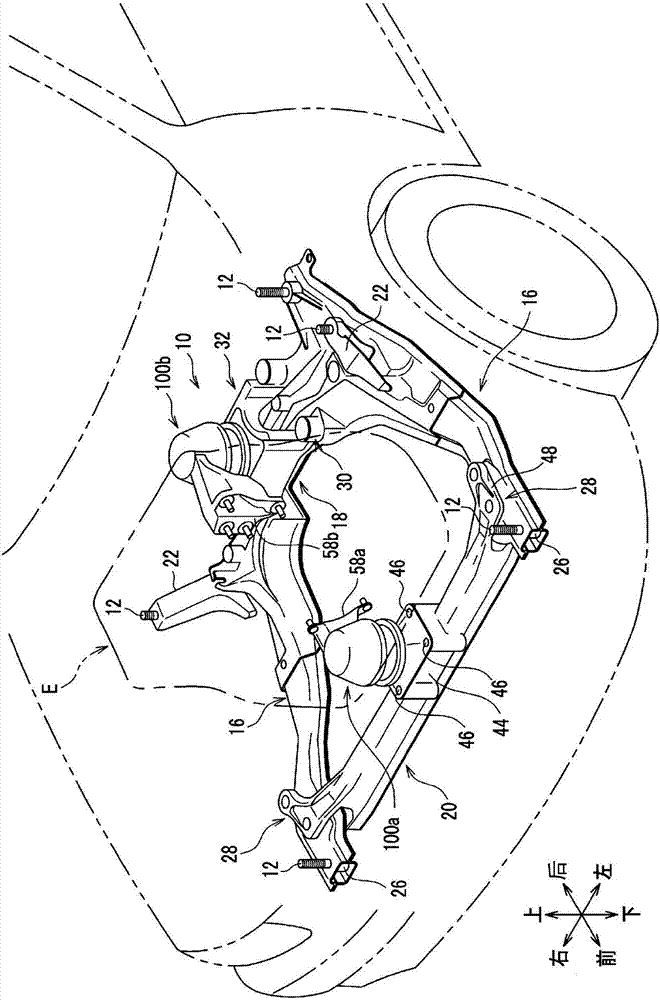

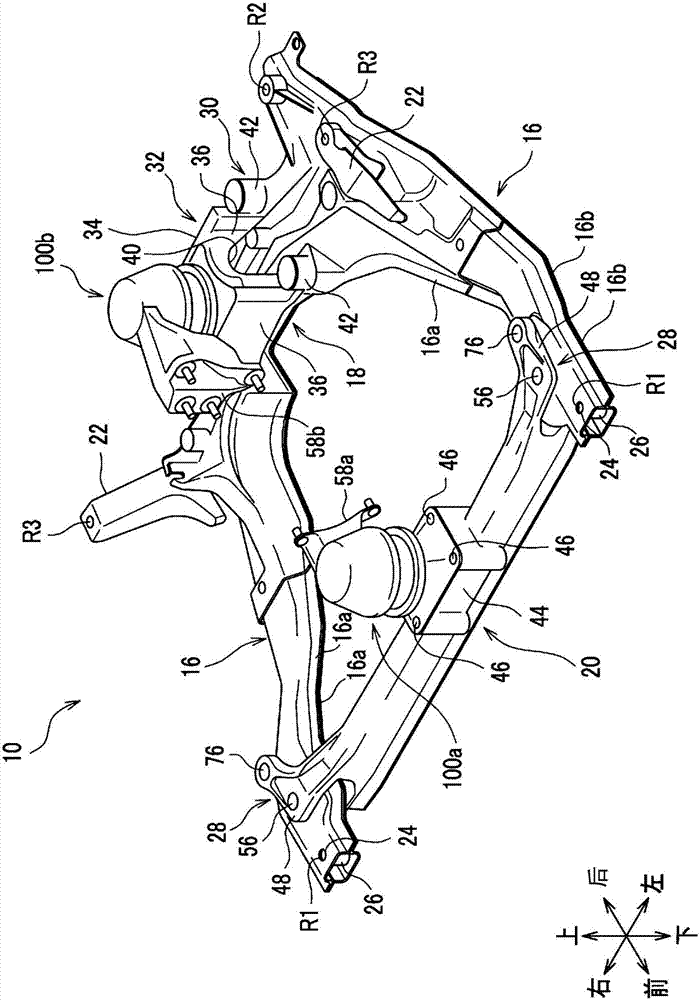

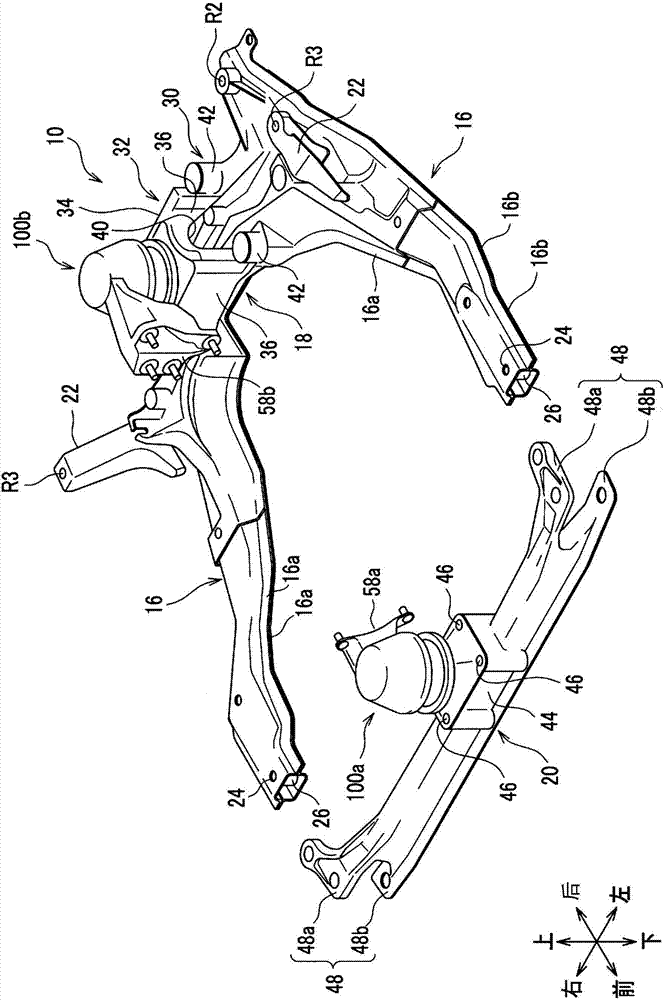

[0032] Next, embodiments of the present invention will be described in detail with reference to the drawings as appropriate. figure 1 It is a transparent perspective view showing a state in which a subframe structure to which a subframe structure according to an embodiment of the present invention is applied is arranged at a front portion of a motor vehicle, figure 2 yes figure 1 The perspective view of the subframe structure shown, image 3 yes figure 2 An exploded perspective view of the subframe structure shown, Figure 4 yes figure 2 A top view of the subframe structure shown, Figure 5 yes figure 2 Side view of the subframe structure shown. In each figure, "front and rear" and "up and down" indicated by arrows indicate the front and rear directions and up and down directions of the vehicle, and "left and right" indicate the left and right directions (vehicle width direction) viewed from the driver's seat.

[0033] Such as figure 1 As shown, the subframe str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com