Soybean milk heating bed

A technology of soybean milk and heating pot, which is applied in the field of soybean product processing, which can solve the problems of wrinkling, different sizes and directions of soybean skin, and achieve the effects of reducing waste, increasing visibility, and reducing sticking to the bottom of the heating pot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

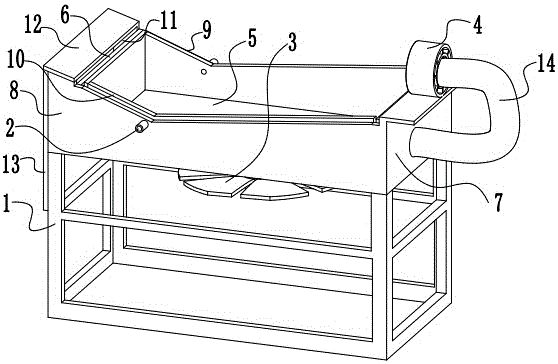

[0025] The reference signs in the drawings of the description include: bracket 1, overflow pipe 2, fan 3, exhaust fan 4, bottom plate 5, left side plate 6, right side plate 7, front side plate 8, rear side plate 9, wooden board 10 , air outlet 11, horizontal plate 12, vertical plate 13, exhaust pipe 14.

[0026] The embodiment is basically as attached figure 1 Shown: the soybean milk heating bed in this scheme includes a support 1 with a rectangular frame structure, a heating pot and a fan 3 installed on the support 1 . The heating pot includes a bottom plate 5 and a left side plate 6 , a right side plate 7 , a front side plate 8 and a rear side plate 9 welded to the bottom plate 5 . The left side plate 6, the right side plate 7, the front side plate 8 and the rear side plate 9 together form a rectangular area, wherein the left side plate 6 and the right side plate 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com