Scale cleaning device for oil pipe external thread

An external thread and oil pipe technology, applied in the field of oil pipe external thread descaler, can solve the problems of increasing the cleaning workload, affecting the efficiency and cleaning quality, dissatisfaction of the oil pipe, etc., so as to improve the cleaning efficiency and quality, reduce the cleaning workload, Thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

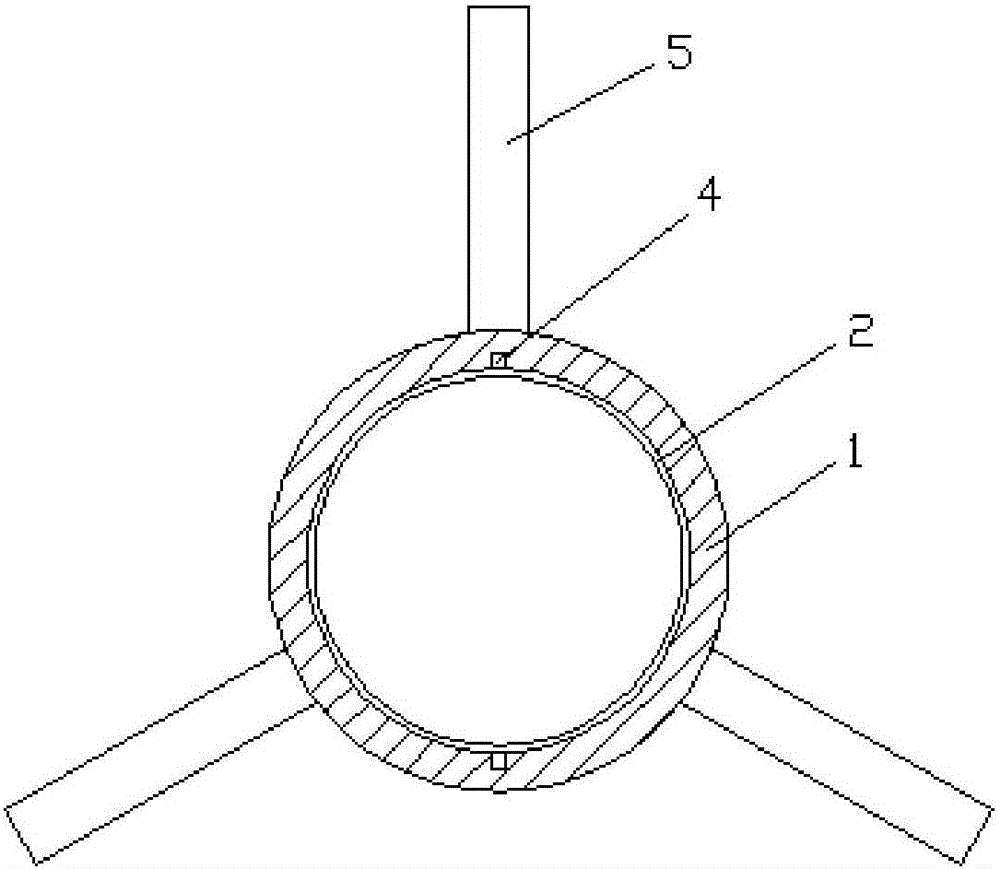

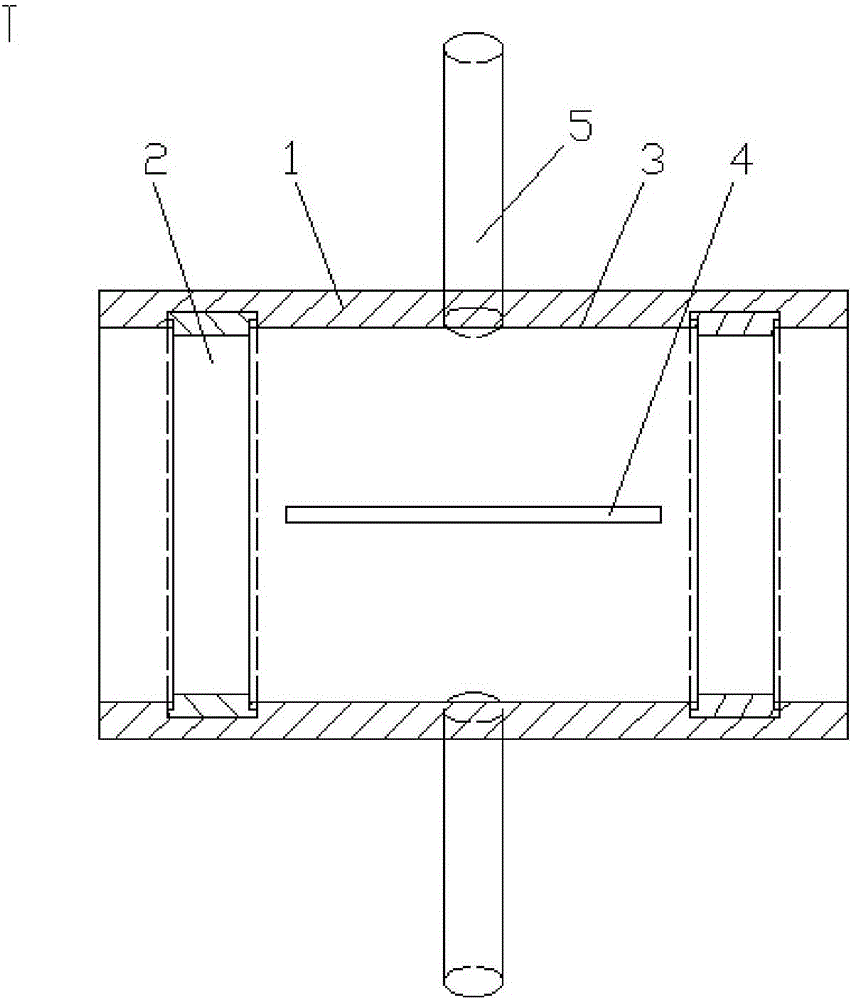

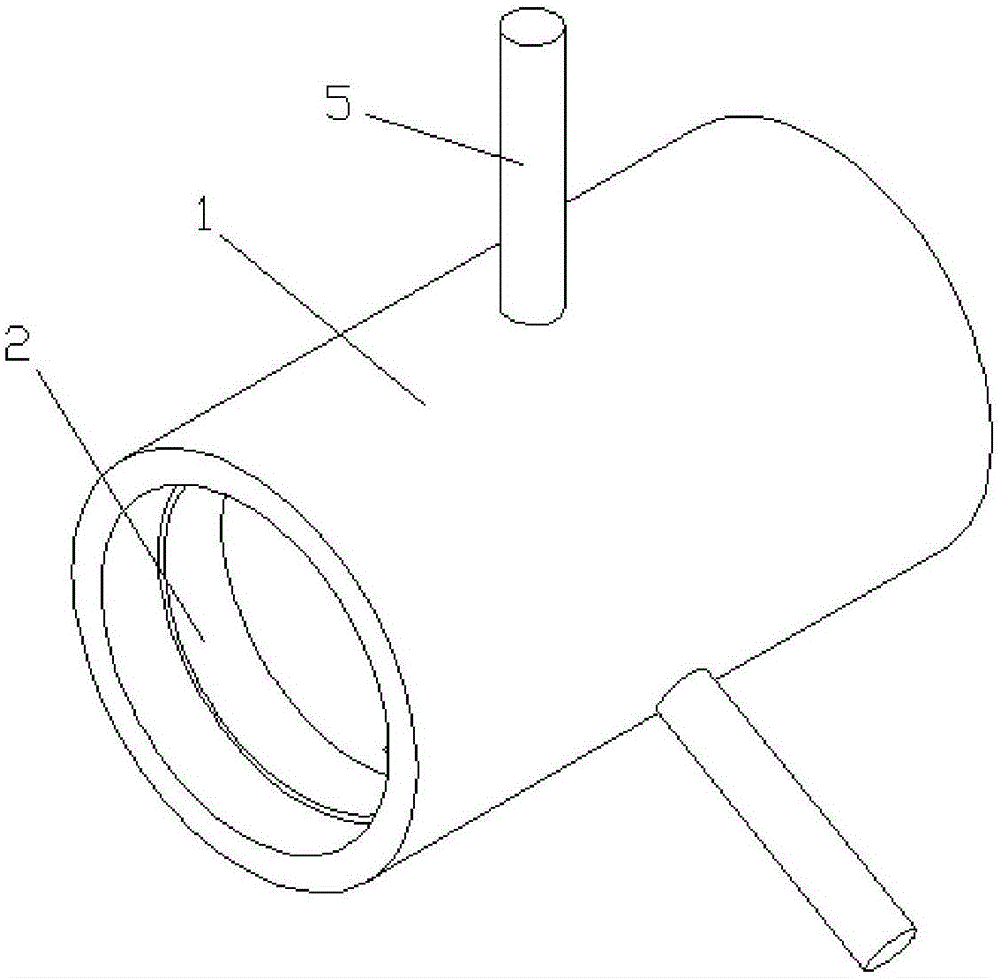

[0016] figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 sectional view of image 3 It is a perspective view of the present invention, as shown in the figure: the oil pipe external thread descaling device of this embodiment includes a cylinder body 1 and a cleaning part 2; the inner wall of the cylinder body 1 is provided with an internal thread 3 that matches the oil pipe external thread The cleaning part 2 is arranged on the inner circumference of the cylinder body 1; the cylinder body 1 with the internal thread 3 and the cleaning part 2 is screwed into the external thread of the oil pipe and then unscrewed to clean the external thread of the oil pipe, and the operation is simple and convenient , the cleaning parts 2 and the external thread are arranged alternately along the axial direction of the cylinder body 1, so that the total length of each cleaning part 2 and the external thread is consistent with the length of the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com