Wood surface minimally invasive device and wood surface treatment method

A wood surface, wood technology, applied in the field of wood surface minimally invasive devices, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment is used to illustrate the wood surface minimally invasive device and wood surface treatment method provided by the present invention.

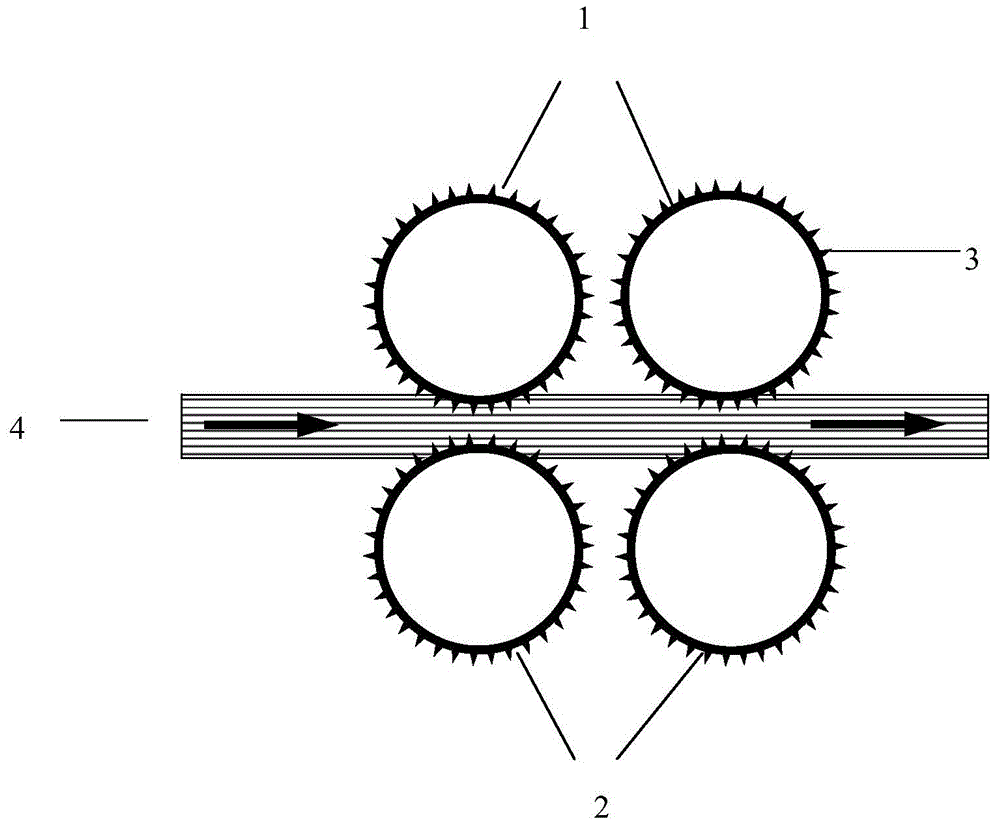

[0051] use as figure 1 The wood surface minimally invasive device shown carries out the minimally invasive treatment of the wood surface, and the wood surface minimally invasive device comprises two driving rollers 2 and two driven rollers 1, and the diameter of the driven roller 1 is 10 times the diameter of the driving roller 2 %, the driven roller 1 is arranged directly above the driving roller 2, and the roller surfaces of the driven roller 1 and the driving roller 2 have needles 3, the needles 3 are conical, and the cross-sectional shape of the needles 3 is rhombus. The vertical section shape from the top of the needle punch 3 to the bottom surface of the needle punch 3 is triangular (the angle of the top is 30°), the distance between the top angles of the needle punch 3 is 2 mm, and the distance between the top ang...

Embodiment 2

[0063] This embodiment is used to illustrate the wood surface minimally invasive device and wood surface treatment method provided by the present invention.

[0064] use as figure 1 The wood surface minimally invasive device shown is for surface treatment of the wood surface, and the wood surface minimally invasive device includes three driving rollers 2 and three driven rollers 1, and the diameter of the driven roller 1 is 15% of the diameter of the driving roller 2 , the driven roller 1 is arranged directly above the driving roller 2, and the roller surfaces of the driven roller 1 and the driving roller 2 have needles 3, the needles 3 are conical, the cross-sectional shape of the needles 3 is rhombus, along the The vertical cross-sectional shape from the top of 3 to the bottom surface of acupuncture 3 is triangular (vertex angle is 40°), the distance between the top angles of acupuncture 3 is 3mm, and the distance between the top angle of acupuncture 3 is from driving roller...

Embodiment 3

[0069] This embodiment is used to illustrate the wood surface minimally invasive device and wood surface treatment method provided by the present invention.

[0070] use as figure 1 The wood surface minimally invasive device shown carries out the minimally invasive treatment of the wood surface, and the wood surface minimally invasive device comprises three driving rollers 2 and three driven rollers 1, and the diameter of the driven roller 1 is 20 times the diameter of the driving roller 2 %, the driven roller 1 is arranged directly above the driving roller 2, and the roller surfaces of the driven roller 1 and the driving roller 2 have needles, the needles 3 are conical, and the cross-sectional shape of the needles 3 is rhombus, along the The vertical cross-sectional shape from the top of 3 to the bottom surface of acupuncture 3 is triangular (vertical angle is 20°), the distance between the top angles of acupuncture 3 is 4mm, and the distance between the top angles of acupunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com