Method for determining preset mode of resin film in RFI process

A technology of preset method and determination method, which is applied in the low-cost field of high-performance resin-based composite materials to achieve the effect of improving penetration efficiency, meeting quality requirements and shortening penetration distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

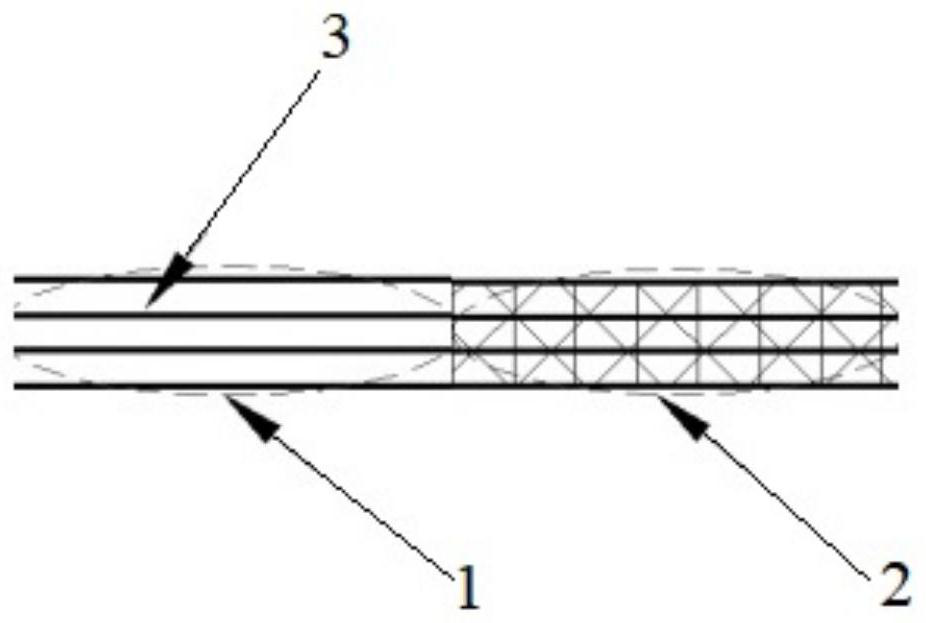

[0106] A panel structure with six T-shaped ribs, the flange of the T-shaped ribs 6 is stitched to the skin 7, formed by the RFI process, and the fiber preform adopts an area density of 160g / m 2 The fiber fabric 3 is laid up, the number of layers of the skin 7 is twenty-five layers, the number of layers of the fiber fabric 3 of the T-shaped rib 6 is sixteen layers, and the fiber density is 1.76g / cm 3 , resin density 1.24g / cm 3 , the fiber volume content requirement is 57%, the tolerance is ±3%, and the surface density is 620g / m 2 A resin film of one specification. The selection method of the resin film preset method is as follows:

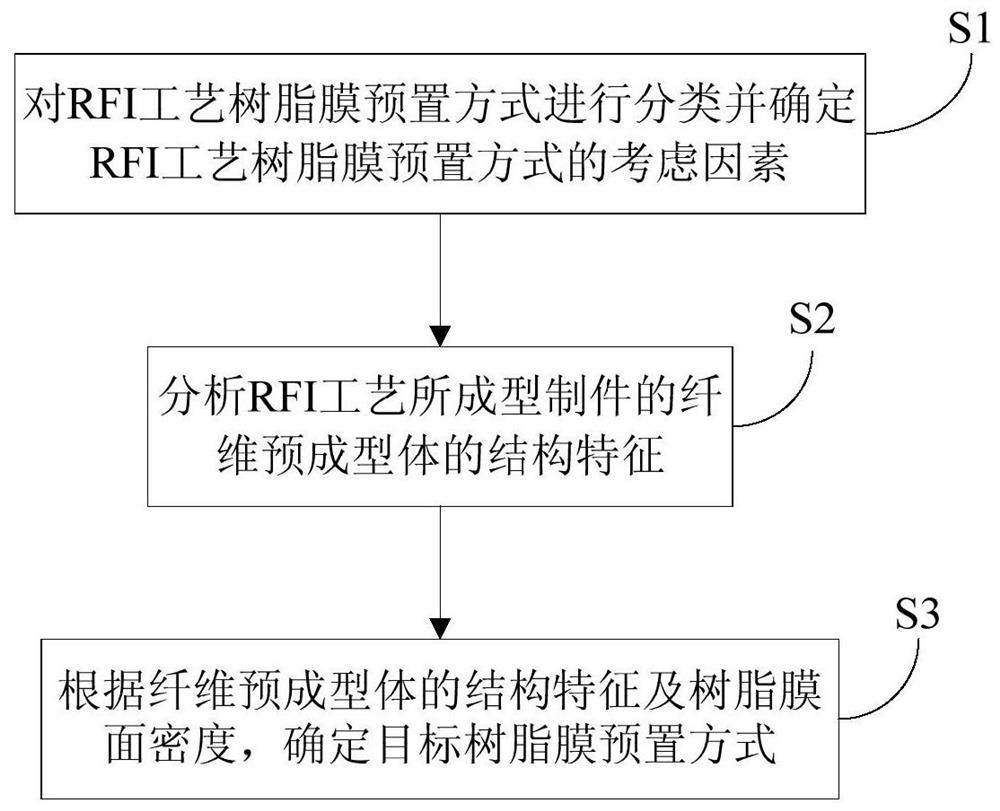

[0107] (a) Classification of RFI process resin film preset methods and factors to be considered in choosing a preset method

[0108] There are two commonly used resin film preset methods in the RFI process: the interlayer preset method and the centralized preset method. Firstly, the specific structural characteristics of the fiber preform are an...

Embodiment 2

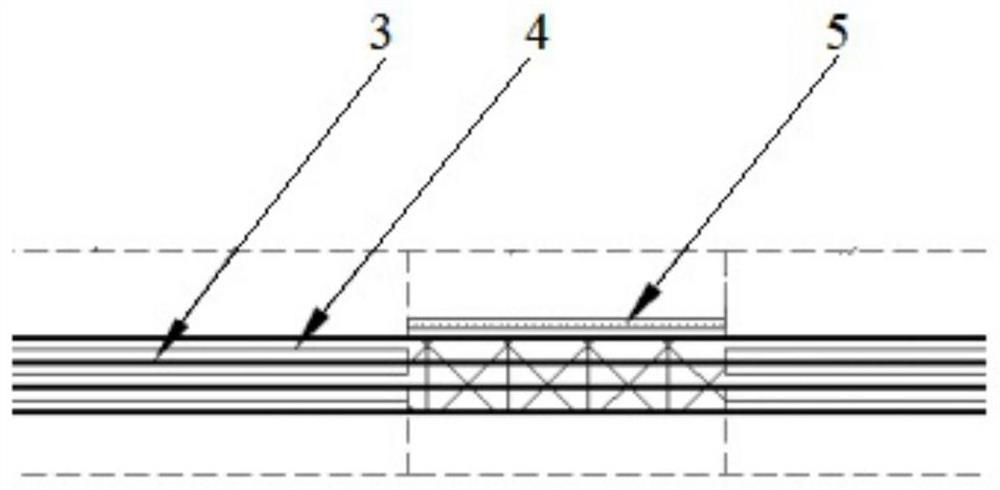

[0132] The wall panel structure with four hat-shaped ribs, the periphery of the skin and the 8 flanges of the hat-shaped ribs are stitched with the skin 7, formed by the RFI process, and the fiber preform adopts an area density of 190g / m 2 The fiber fabric 3 is laid up, the number of layers of the fiber fabric 3 of the skin is twenty layers, the number of layers of the fiber fabric 3 of the cap rib 8 is twelve layers, and the fiber density is 1.8g / cm 3 , resin density 1.24g / cm 3 , the fiber volume content requirement is 58%, the tolerance is ±3%, and the surface density is 620g / m 2 and 105g / m 2 Two specifications of resin film. The selection method of the resin film preset method is as follows:

[0133] (a) Classification of RFI process resin film preset methods and factors to be considered in choosing a preset method

[0134] There are two resin film preset methods in the RFI process: the interlayer preset method and the centralized preset method. Firstly, the specific s...

Embodiment 3

[0172] Combination structure composed of glass fiber fabric and three-dimensional weaving body, the thickness direction consists of fifty-six layers of glass fiber fabric 3 and surface density 35kg / m 2 The three-dimensional weaving body is combined, and it is formed by RFI process. The three-dimensional density of the fiber fabric is 100g / m 2 , fiber density 2.2g / cm 3 , resin density 1.24g / cm 3 , the fiber volume content requirement is 56.5%, the tolerance is ±2%, and the surface density is 125g / m 2 and 1240g / m 2 Two specifications of resin film. The selection method of the resin film preset method is as follows:

[0173] (a) Classification of RFI process resin film preset methods and factors to be considered in choosing a preset method

[0174] For the selection of the two resin film preset methods of the interlayer preset method and the centralized preset method in the RFI process, it is necessary to consider the specific structural characteristics of the fiber preform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com