A method and system for reducing particulate matter emission during warm-up period of direct injection gasoline engine at low temperature

A warm-up stage, particulate matter technology, applied in the direction of machine/engine, engine cooling, mechanical equipment, etc., can solve the problems that affect the driving experience of the engine power output, fail to reach the regeneration temperature condition, and insufficient air mixing, etc., to achieve improved The effect of fuel atomization, reducing the penetration distance of fuel injection, and reducing complaints

Active Publication Date: 2022-05-31

DONGFENG MOTOR CORP HUBEI

View PDF20 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

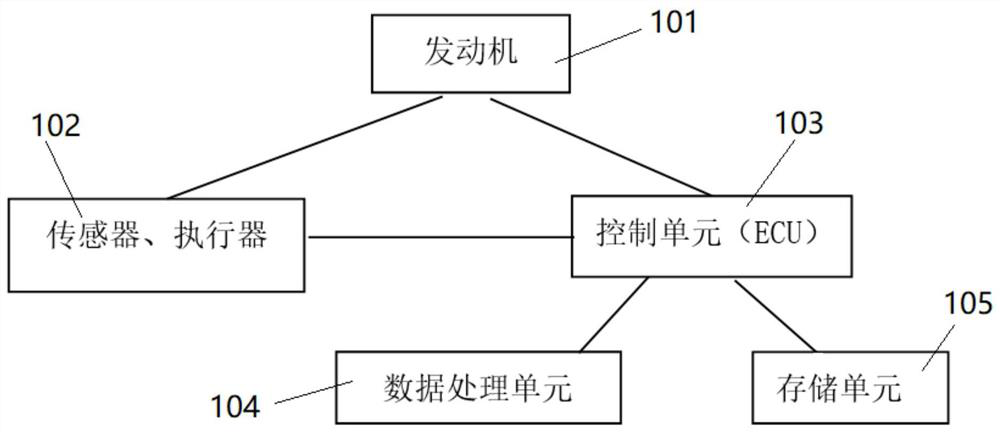

[0002] With the implementation of National 6 emission and fuel consumption regulations for passenger cars, gasoline engines with in-cylinder direct injection are mostly used in vehicle engines, and direct injection gasoline engines are mostly installed with particle traps GPF (Gasoline Particle Filter) to achieve particulate matter emissions Requirements of regulatory objectives, low temperature (temperature lower than -15°C or lower), low speed driving environment, the engine just started, the water temperature is low, the volatility of gasoline is low, and the gasoline sprayed into the cylinder with a single injection is not atomized well. Insufficient mixing with air, insufficient combustion, forming a large amount of particulate matter, which is captured by the GPF. If several driving cycles have been driven at a lower speed, the temperature of the GPF is low (the regeneration temperature cannot be reached), and the GPF will Without good regeneration, particulate matter will quickly accumulate and block the GPF, affecting engine power output and driving experience, and even damage the engine in severe cases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

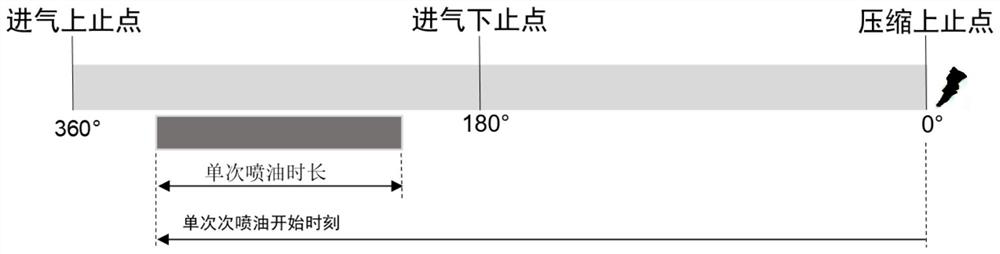

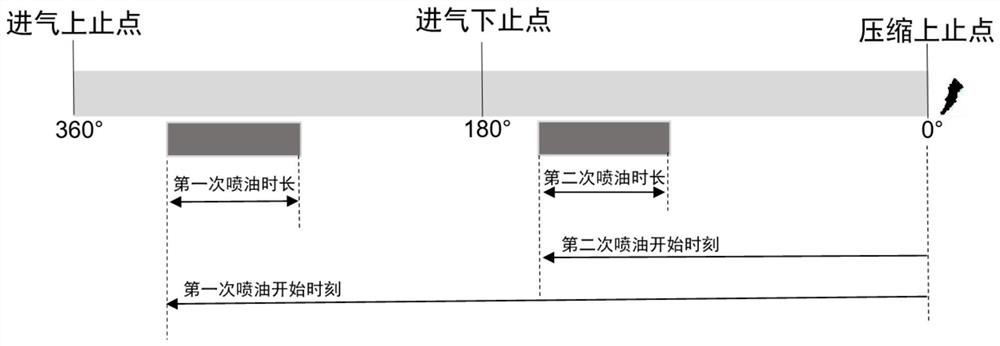

[0033] As shown in Figure 2 and Figure 3, the single injection is in the engine intake stroke, and the first injection of the two injections is in the intake stroke,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The method and system designed by the present invention for reducing the discharge of particulate matter in the warm-up stage of a direct-injection gasoline engine at low temperature are characterized in that the atomization effect of fuel oil in the low-temperature warm-up stage is improved, and the generation of particulate matter is effectively reduced. Increase the fuel injection pressure, and take multiple (generally two) injections at the same time, shorten the time of each injection and reduce the penetration distance of the injection, thus avoiding the excessive fuel injection to the engine cylinder wall (or piston) after the pressure is increased. Risk of particulate matter and oil emulsification. The invention reduces the emission of particulate matter from the engine during the warm-up period under low-temperature and low-speed driving cycles, can effectively reduce the direct emission of particulate matter when there is no GPF, and can avoid the risk of GPF blockage in a short time (several low-temperature and low-speed driving cycles) when there is GPF , to reduce complaints from customers that they need to deliberately run high-speed carbon removal (to regenerate GPF).

Description

A method and the system technical field The invention belongs to the technical field of automobile control, specifically a kind of particle that reduces the warm-up stage of direct injection gasoline engine at low temperature method of discharge. Background technique With the implementation of the national 6 emission and fuel consumption regulations of passenger cars, the gasoline of the direct injection mode in the cylinder is mostly used in vehicle engines. Most of the direct injection gasoline engines are equipped with a particle catcher GPF (Gasoline Particle Filter) to achieve To meet the requirements of particulate emission regulatory targets, in low temperature (temperature below ‑15°C or lower), low speed driving environment, engine Just started, the water temperature is low, the gasoline volatility is low, the gasoline injected into the cylinder by a single injection is not well atomized, and it is not mixed with the air. If it is not fully burned, a lar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02D41/04F02D41/06F02D41/40F01P11/16

CPCF02D41/04F02D41/068F02D41/40F02D41/401F02D41/402F01P11/16F02D2200/101F02D2200/602F02D2200/0414Y02T10/40

Inventor 邹亚张翼陈龙肖文涛

Owner DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com