Swelling device with middle screen guide rod and for accelerating dissolution of polymer

A polymer and guide rod technology, applied in the direction of dissolution, dissolution, mixer, etc., can solve the problems of long polymer dissolution time, large area occupied by the device, and polymer preparation process that cannot be applied on offshore platforms, etc., to achieve shortening Dissolving time, reducing occupied space and load bearing, accelerating interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

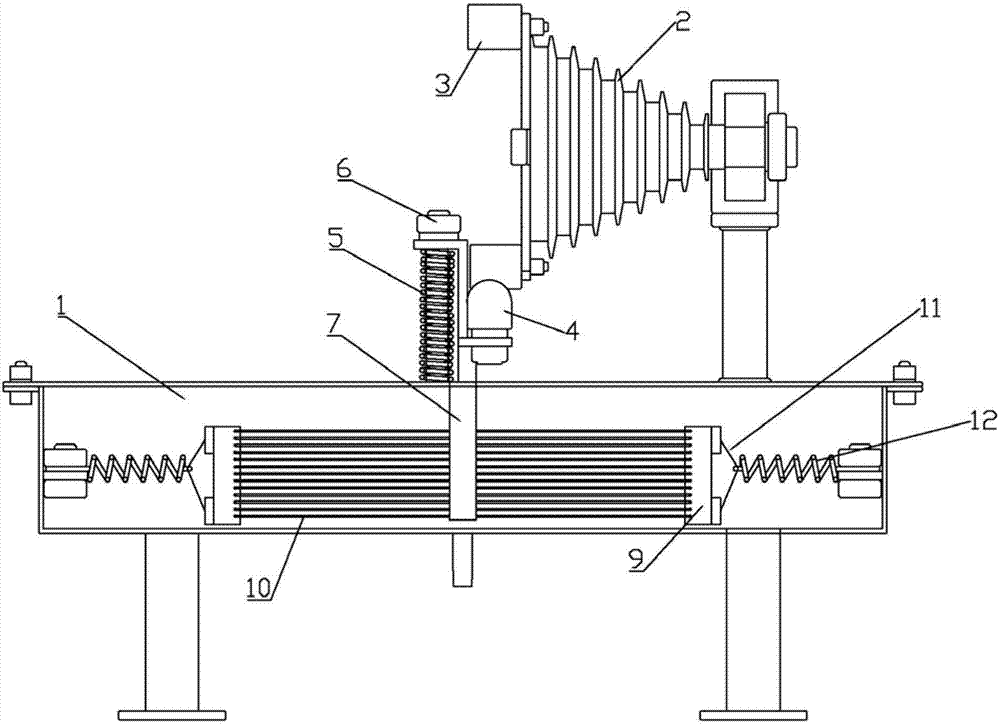

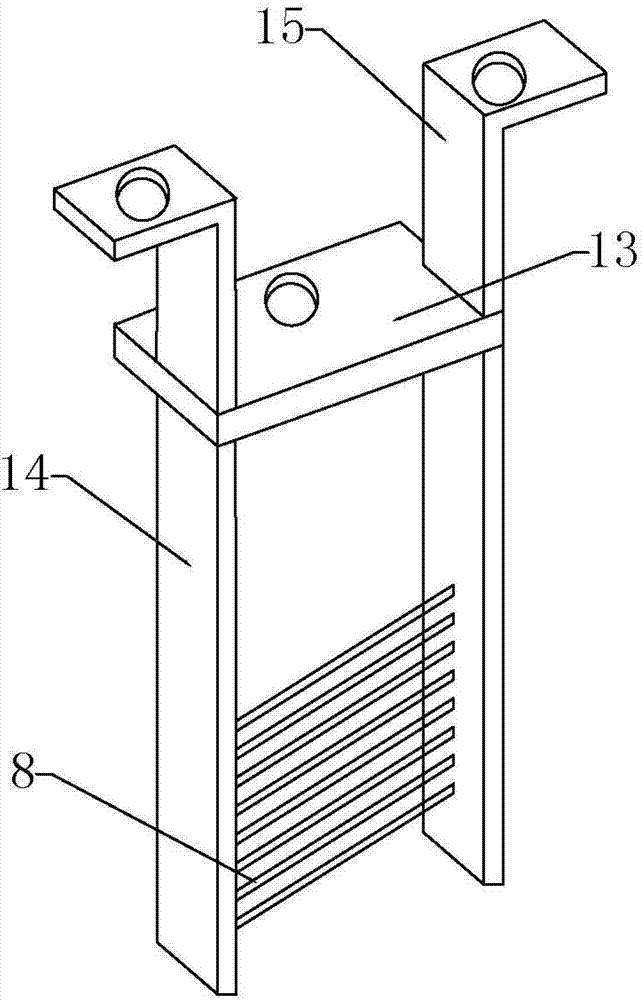

[0019] Such as figure 1 and figure 2 It is known that the tenting device for accelerating polymer dissolution with an intermediate net guide rod is composed of a power system, a motion conversion system, a vibration source system and a container 1. The power system is composed of a moving wheel 2, and the motion conversion system is composed of a beat bar , contact 4, return spring 5, intermediate net guide rod 6, and intermediate net frame 7. The rod 6 is located on both sides of the middle net frame 7, and one end of the middle net guide rod 6 is provided with a bolt and is fixed on the container 1 through the middle net frame 7 and the return spring 5 in turn, and the middle net frame 7 and the return spring 5 can be fixed on the middle net. The guide rod 6 is movable, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com