A kind of protection device and protection method of ink nozzle

A protection device and nozzle technology, which is applied in printing and other directions, can solve the problems of easy rupture of the capsule tube, too compact position of the nozzle bracket, damage to nozzle accessories, etc., to prolong the service life of the nozzle, the protection method is simple and effective, and the service life is extended Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

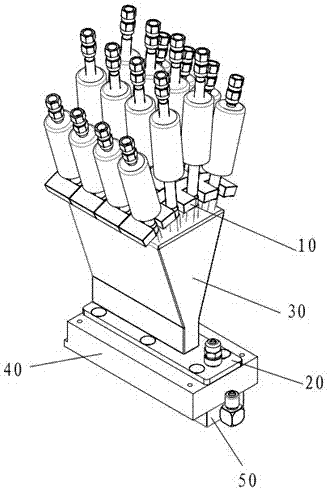

[0039] Such as Figure 1-Figure 4 As shown, a protection device for an ink nozzle includes:

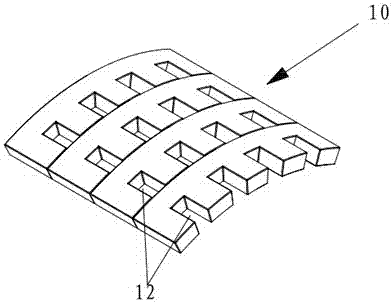

[0040] The nozzle holder 10 is provided with a plurality of first through holes 12 spaced apart on the nozzle holder 10 for separating the nozzle 1; reference figure 2 , The nozzle holder 10 has a certain arc as a whole, and the spacing between the first through holes 12 is designed according to the size of the nozzle, and the solenoid valve of the nozzle is not crowded and is easy to adjust;

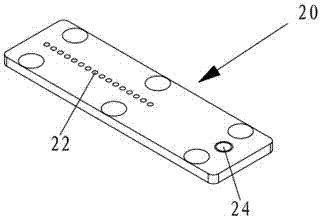

[0041] The nozzle bracket 20, the nozzle bracket is located below the nozzle bracket 10, the nozzle bracket 20 is provided with a plurality of second through holes 22 for separating the bladder tube 2 of the nozzle at intervals; image 3 The second through holes 22 are linearly arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com