Eddy current vibration device

A vibrating device and driving device technology, which is applied to vibration generating devices, drilling with vibration, wellbore/well components, etc., can solve the problems of short service life, low vibration efficiency, high vibration frequency, etc., and achieve excellent vibration effect and high pressure. The effect of low consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

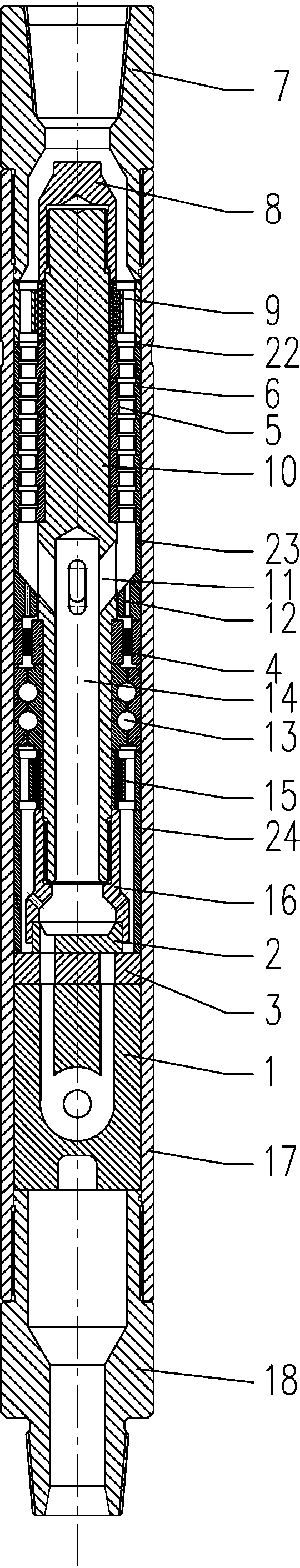

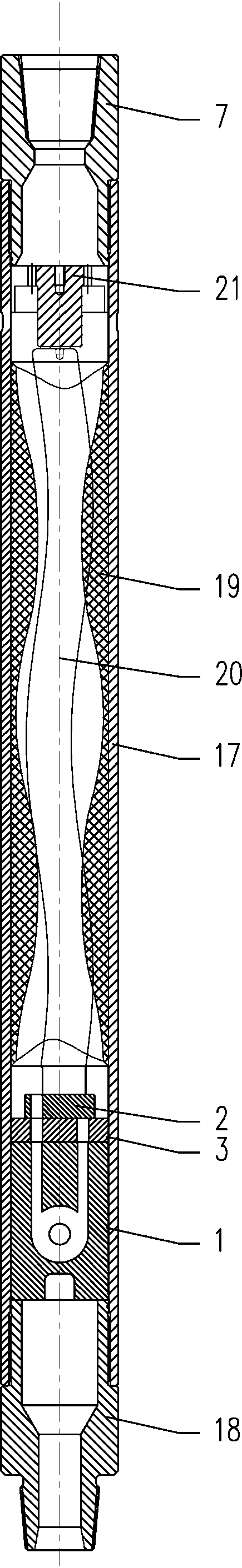

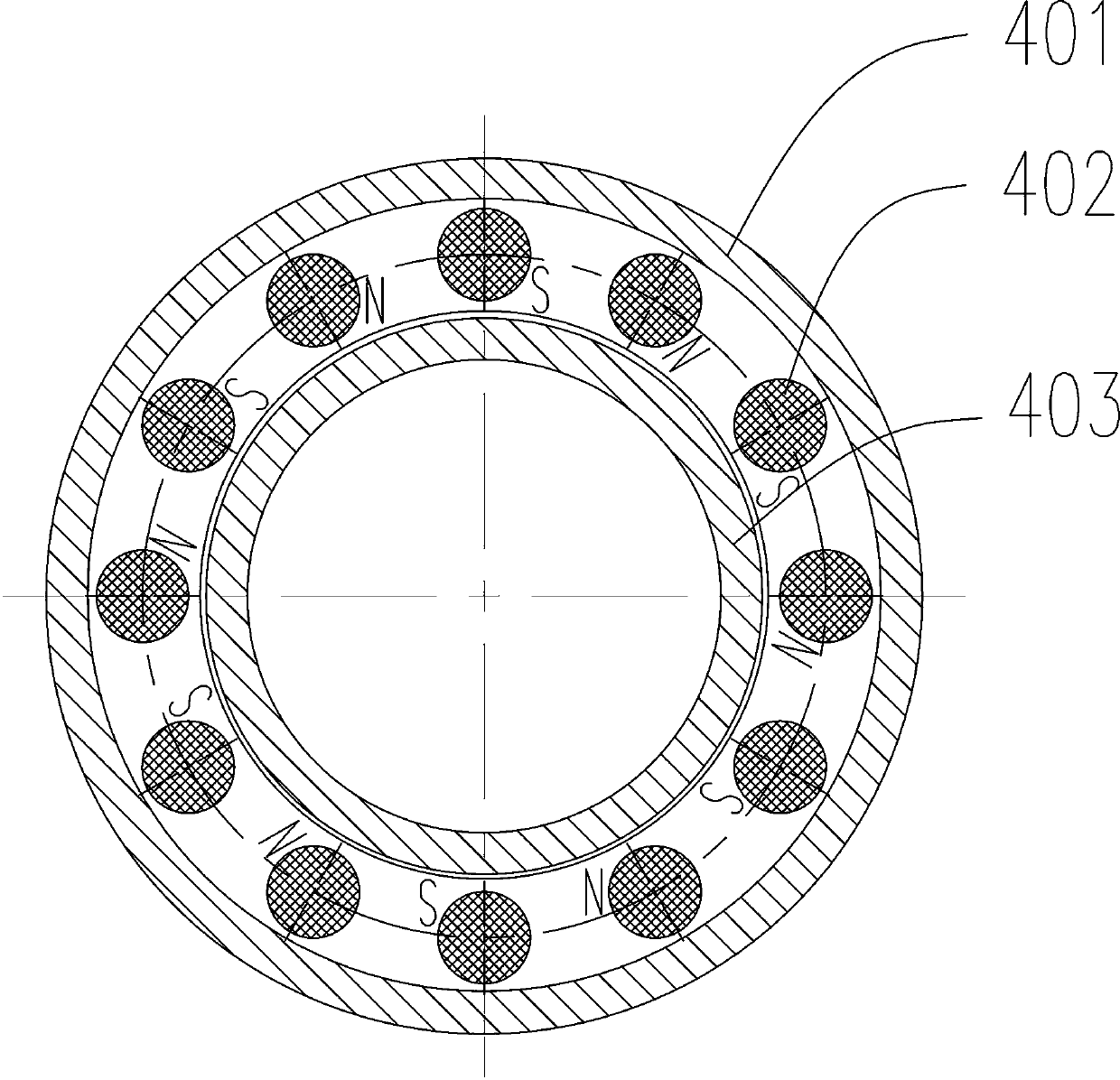

[0045] Such as Figure 1~5 Among them, an eddy current vibration device includes a housing 17, the upper end of the housing 17 is connected to the upper joint 7, and the lower end is connected to the upper joint 7, see figure 1 , 2 middle.

[0046] The housing 17 is provided with a movable valve plate 2 driven to rotate by the driving device, and the vibrating device 1 is provided with a circular vortex chamber 103, specifically, the vortex chamber 103 is cylindrical. At least one liquid inlet groove 101 is connected tangentially to the vortex cavity 103, and the center of the vortex cavity 103 is provided with a vortex cavity outlet 104, and the vortex cavity outlet 104 is connected to the liquid outlet 105; when the high-pressure liquid flow hits the vortex cavity 103, a Vibration, and then the liquid flow is discharged from the outlet 104 of the vortex chamber.

[0047] At least one bypass channel 102 is connected to the liquid outlet 105; when the liquid flows out from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com