Oil supply hydraulic adjusting device for piston cooling nozzle performance experiment bench

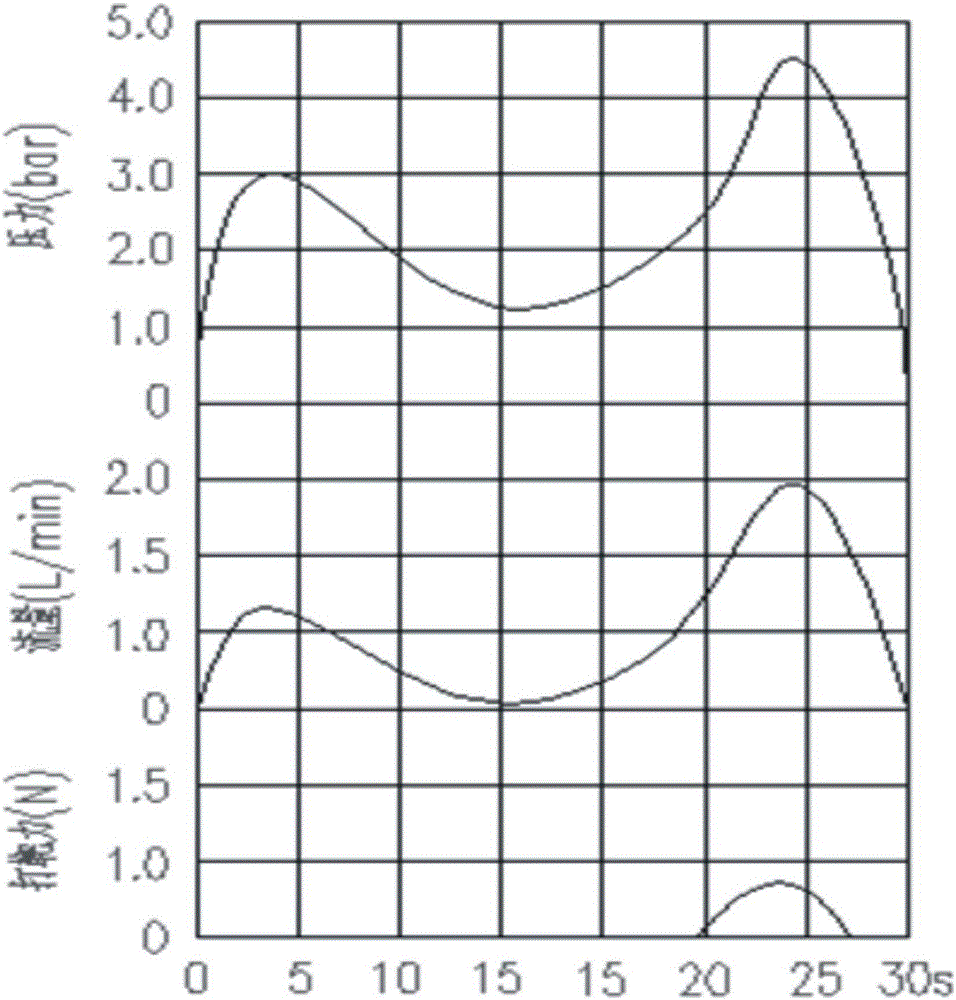

A technology of hydraulic adjustment device and piston cooling nozzle, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc. It can solve the problems of time-consuming operation, large temperature rise of medium oil, and user inconvenience. , to achieve the effect of easy to use, save experimental test time, and increase the gradient of pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

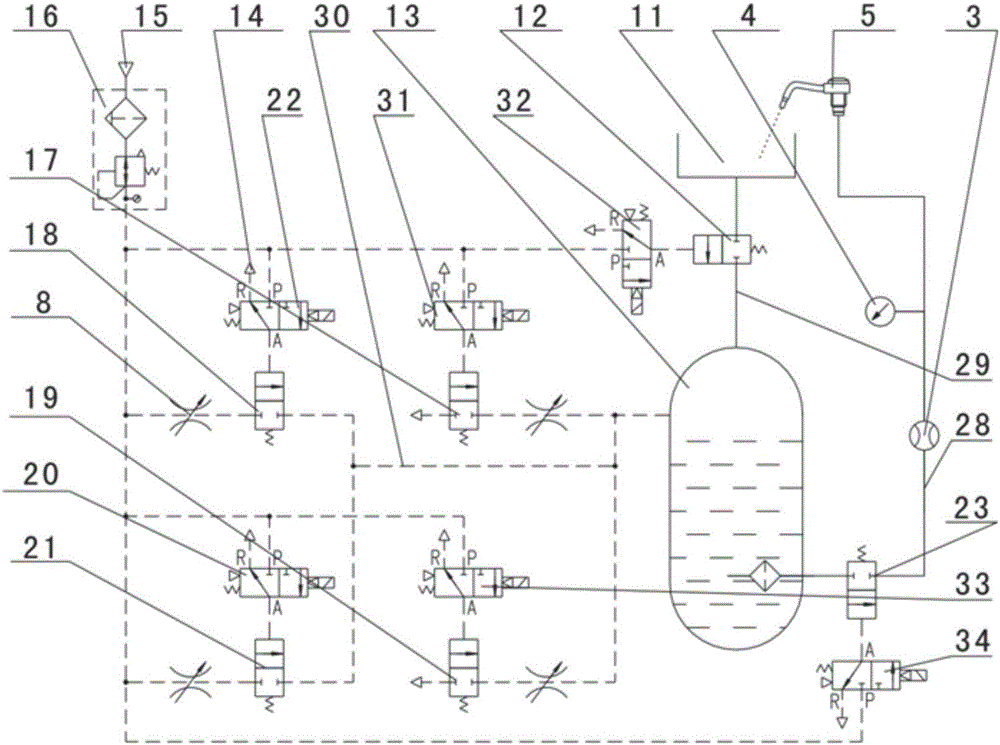

Method used

Image

Examples

Embodiment Construction

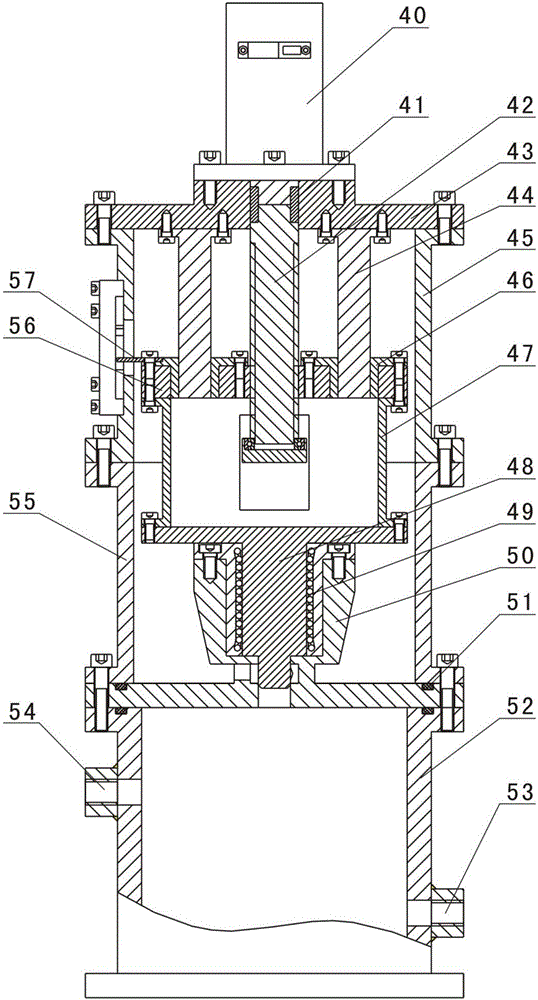

[0055] The present invention will be further described below in conjunction with accompanying drawing:

[0056] Such as Figure 3-Figure 20 As shown, the oil supply hydraulic adjustment device for the piston cooling nozzle performance test bench of the present invention includes a stepper motor 40, a round key 41, a screw 42, a thrust plate 64, a deep groove ball bearing 63, Guide rod 44, top plate 43, support cylinder 45, moving plate 56, copper sliding sleeve 46, follower cylinder 47, moving shaft 48, oil retaining cylinder 55, oil return pipe 66, linear bearing 49, bearing seat 50, auxiliary oil tank 52, auxiliary oil tank The oil inlet 54 on the top of the 52 is connected to the oil outlet of the oil supply source (not shown in the figure), and the oil outlet 53 on the lower part of the auxiliary oil tank 52 is connected to the piston cooling nozzle (see Figure 22 , Figure 23 The oil inlet of the piston cooling nozzle 114) is connected, the bottom plate of the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com