Multifunctional hydraulic combination valve

A hydraulic combined valve and multi-functional technology, applied in the field of hydraulic valves, can solve the problems of high manufacturing cost, multiple auxiliary components, complex structure of the unloading solenoid valve, etc., achieve convenient manufacturing and processing, meet the needs of system work, and ensure normal work. Effects of Temperature and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

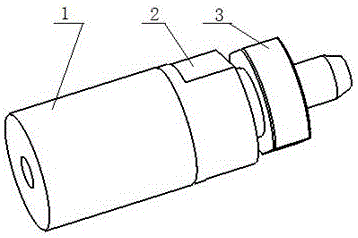

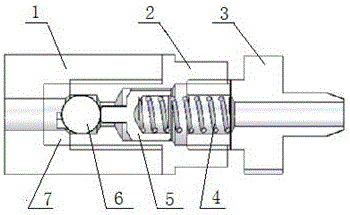

[0030] Embodiment of the present invention: a multi-functional hydraulic combination valve, as shown in the accompanying drawings, includes a valve seat 1, an oil drain screw 3 is installed on the right side of the valve sleeve 2 through a threaded connection, and the valve sleeve 2 is installed on the valve seat through a threaded connection 1 on the right side, a steel ball installation hole 8 is set on the left side of the valve sleeve 2, and a valve seat step shaft hole 9 is set on the right side of the valve seat 1, and the steel ball seat 7 is installed in the valve seat step shaft hole 9 and the steel ball The seat 7 is aligned with the steel ball mounting hole 8, the steel ball 6 is placed in the steel ball mounting hole 8 and can move in the steel ball mounting hole 8 and the steel ball seat 7, the core rod 5 is installed in the middle of the valve sleeve 2 and the core The ejector rod 10 of the rod 5 corresponds to the steel ball 6, the spring 4 is installed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com