Rotary plate type gas distribution valve

A technology of rotating disk and rotating disk, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of poor sealing and complex structure, and achieve the effect of good sealing, simple maintenance and reducing safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

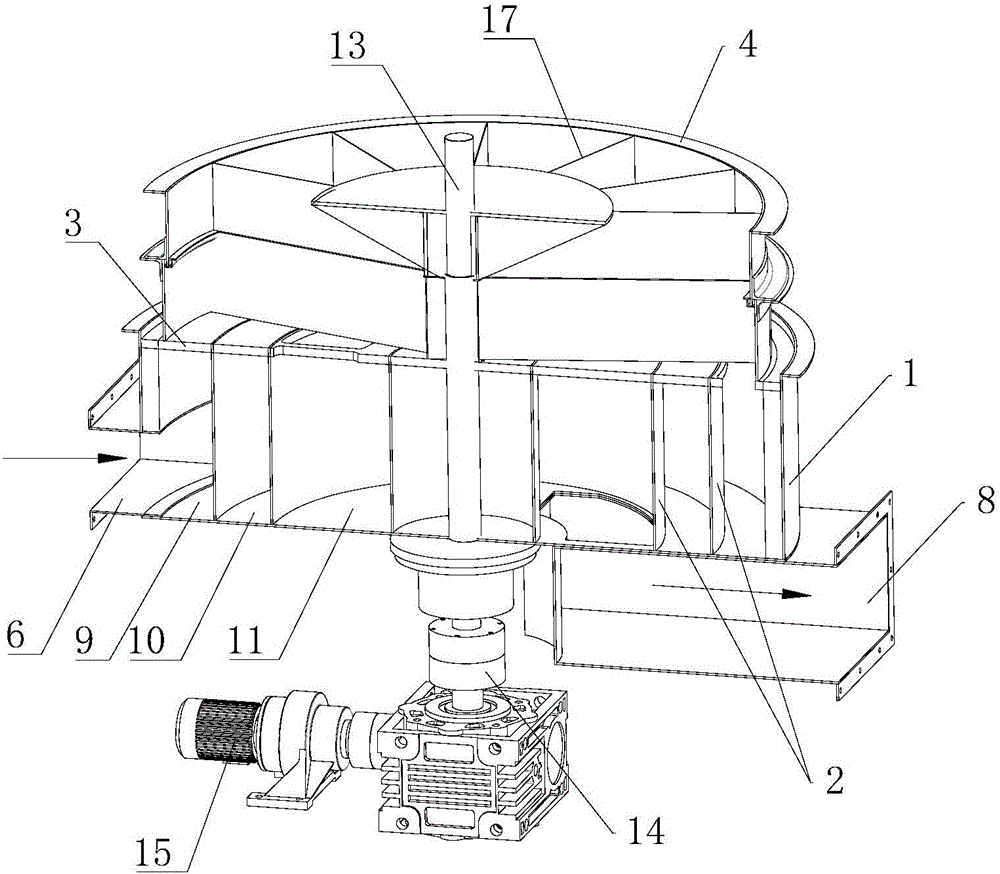

[0035] Such as figure 1 As shown, it is an embodiment of the rotary disk gas adjusting valve of the present invention, the gas adjusting valve can realize the air inlet and outlet while changing the wind direction, and the gas can be continuously sent in and out.

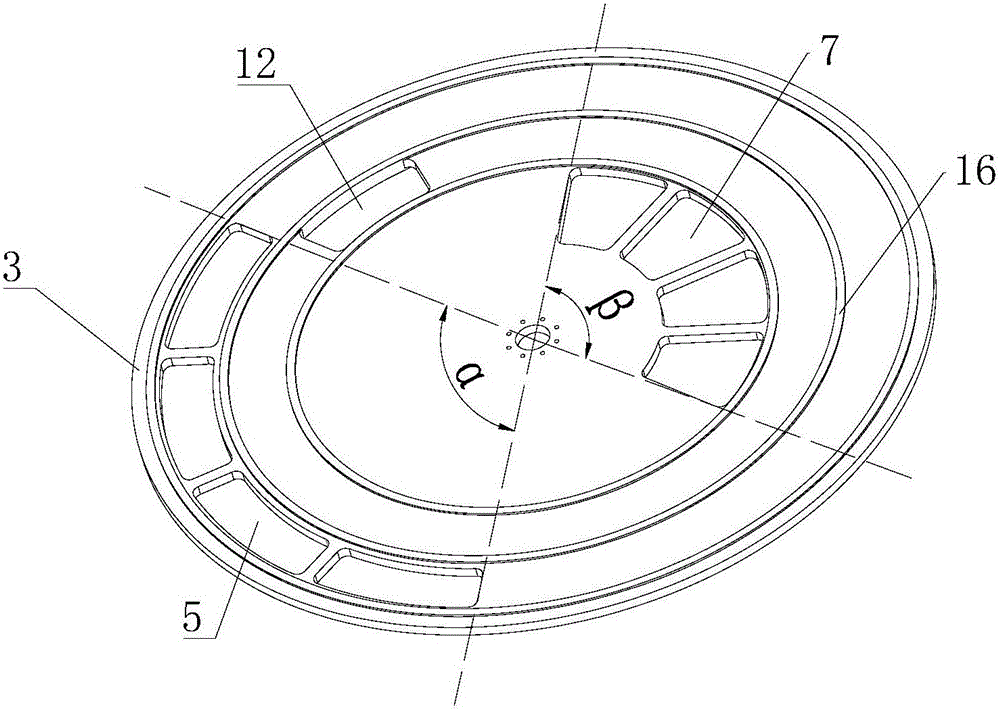

[0036] The rotary disc gas adjusting valve firstly includes a cylindrical casing 1, the casing 1 has a lower end surface and an outer peripheral surface, the upper end surface of which is open. A circular partition 2 arranged concentrically with it is fixed inside the casing 1, and the number of the circular partitions 2 shown in this embodiment is two, and these two circular partitions 2 are arranged inside the cylindrical casing 1. The cavity is divided into three independent cavities, and the three independent cavities are concentric rings.

[0037] A rotating shaft 13 runs through the central axis of the housing 1, and the rotating shaft 13 is connected to the driving device 15 through a coupling 14. Under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com