Wall hanging stove gas supply pipeline safety monitoring system

A technology for gas supply pipelines and safety monitoring, which is used in household stoves/stoves, lighting and heating equipment, solid heating fuels, etc. It can solve the problems of natural gas leakage users getting sick and high fuel use costs, and achieve higher use costs and collection ratios. for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

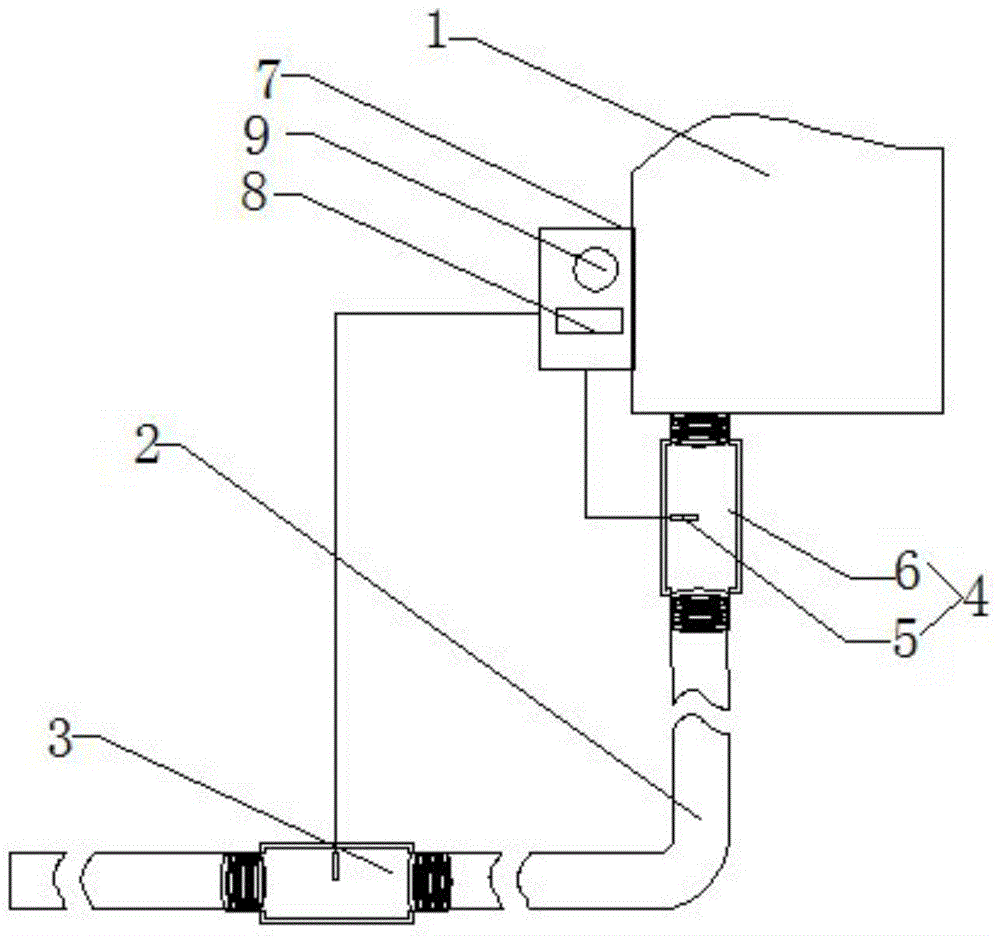

[0015] Such as figure 1 The safety monitoring system for the gas supply pipeline of the wall-hung boiler includes a wall-hung boiler 1 and a pipeline 2 for supplying gas to the wall-hung boiler. Quantitative acquisition module 3 and the second quantitative acquisition module 4; The first quantitative acquisition module 3 and the second quantitative acquisition module 4 are made of flow probe 5 and standard tube 6; The flow probe 5 is connected to the control system 7; The control system 7 is equipped with a comparison module; the control system 7 is also electrically connected to a display 8; the standard pipe 6 is threaded with the gas supply pipeline 2 of the wall-hung boiler; the first quantitative acquisition module 3 It is the same model as the second quantitative acquisition module 4; the control system 7 is also electrically connected with a light alarm and / or an acoustic alarm 9.

[0016] During use, after the first quantitative acquisition module 3 and the second qua...

Embodiment 2

[0018] Such as figure 1 The safety monitoring system for the gas supply pipeline of the wall-hung boiler includes a wall-hung boiler 1 and a pipeline 2 for supplying gas to the wall-hung boiler. Quantitative acquisition module 3 and the second quantitative acquisition module 4; The first quantitative acquisition module 3 and the second quantitative acquisition module 4 are made of flow probe 5 and standard tube 6; The first quantitative acquisition module 3 and the second quantitative acquisition module The quantitative acquisition module 4 is also separately provided with a controller (not shown); the controller is electrically connected to the flow probe 5; the controller is also electrically connected to a wireless transmitter (not shown); the wireless transmitter cooperates A wireless receiving device is installed; the wireless receiving device is equipped with a control system 7; the control system 7 is provided with a comparison module; the control system 7 is also elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com