Gradient drying device for pine nuts

A drying device and gradient technology, applied in the field of pine nut gradient drying device, can solve the problems of poor drying effect and low drying efficiency, and achieve the effect of avoiding mildew and overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

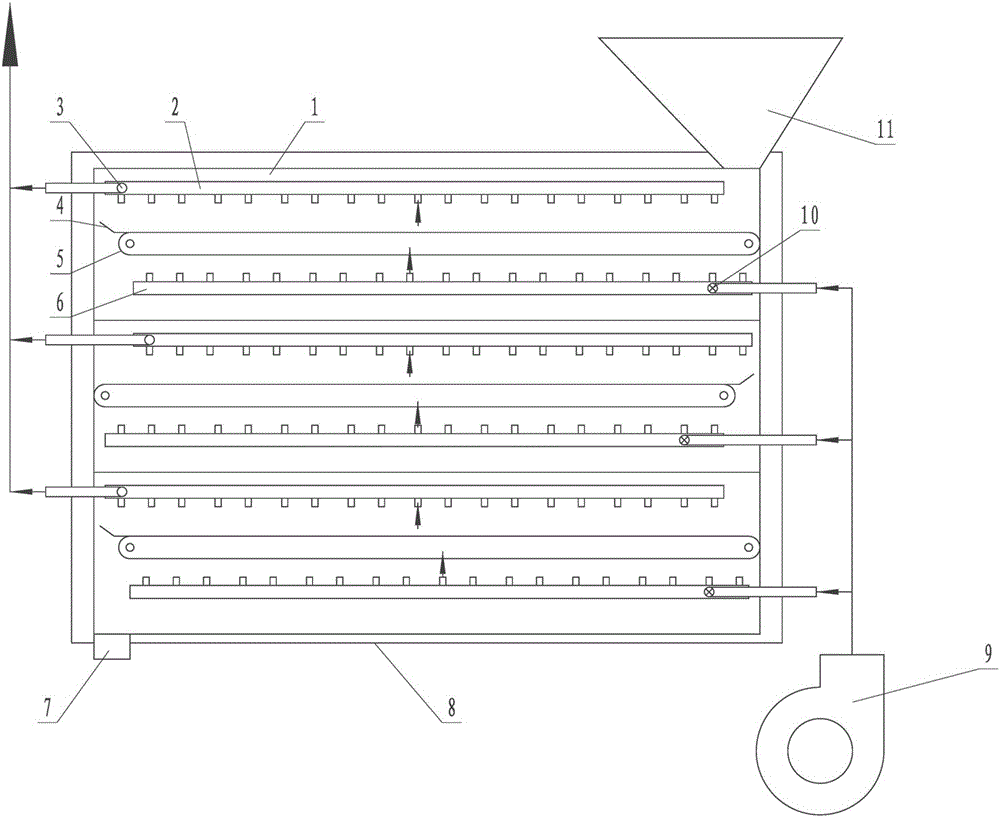

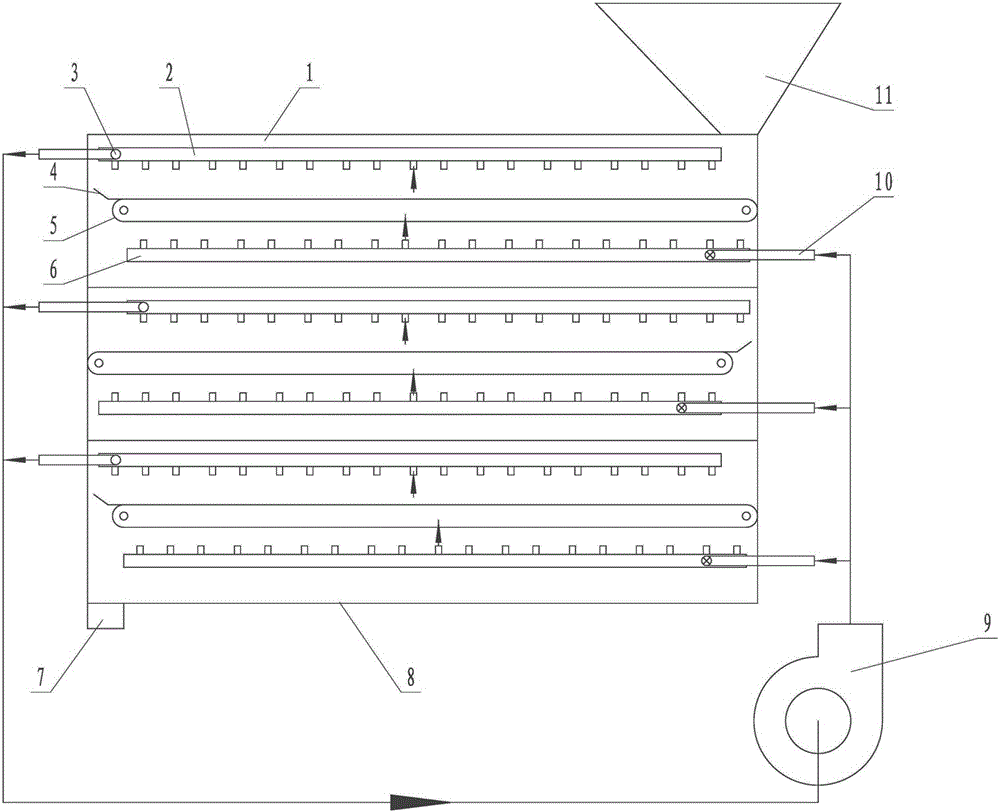

[0020] The pine nut gradient drying device includes a thermal insulation shell 8 arranged on a horizontal plane, a fan 9, and three sequentially connected drying units 1 arranged vertically from top to bottom, which are arranged in the thermal insulation casing and connected to the fan. A hopper 11 is provided on the drying unit at the front end, and a discharge port 7 is provided at the bottom of the drying unit at the end. The drying unit includes a drying shell, a conveyor belt 5 made of metal mesh arranged in the drying shell, an exhaust main pipe 2 arranged above the conveyor belt, and an air inlet main pipe 6 arranged below the conveyor belt. The end of each conveyor belt is provided with an upturned baffle plate 4, and there is a gap of a certain width between the baffle plate and the inner wall of the housing of the drying unit. The lower drying unit falls into the lower drying unit when being squeezed by pine nuts, so as to avoid hindering the movement of pine nuts. ...

Embodiment 2

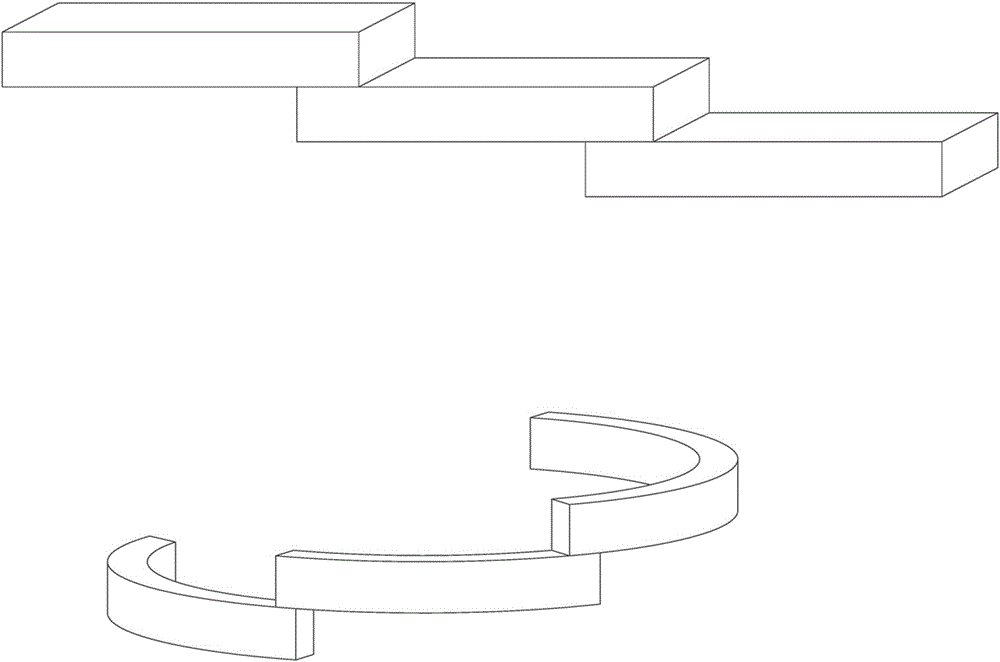

[0022] The combined layout of each drying unit is not unique. In addition to the vertical layout of Embodiment 1, in order to meet the needs of the actual site, the following can also be used: Figure 4 The ladder shape and ring shape are shown, but the floor space of the ladder shape layout is too large, the material consumption of each unit shell is large, and the insulation effect is poor, which is not conducive to saving manufacturing and use costs, so it is usually not used. Although the ring layout occupies a smaller area than the stepped layout, it is not usually used.

[0023] The conveyor belt in each technical solution of the present invention can be a belt with a through hole, or a metal mesh can be used directly. Since metal has a better heat conduction effect and is more conducive to drying, the metal mesh is preferred.

[0024] The thermal insulation shells in the various technical solutions of the present invention can be respectively arranged outside each dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com