High-voltage power transformer for improving wire clamping strength

A high-voltage transformer and clamping technology, which is applied in the field of high-voltage electric power, can solve problems such as restrictions on the application and promotion of high-voltage transformers, and achieve the effects of reasonable center of gravity distribution, vibration reduction, and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

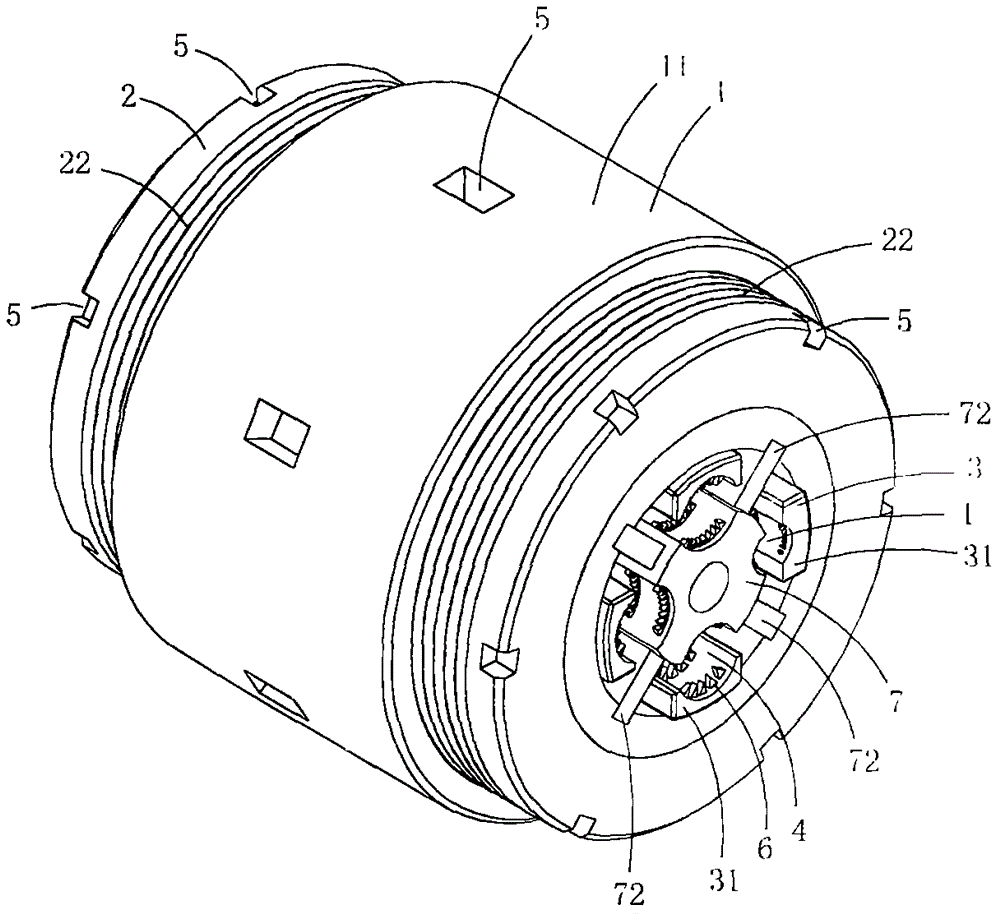

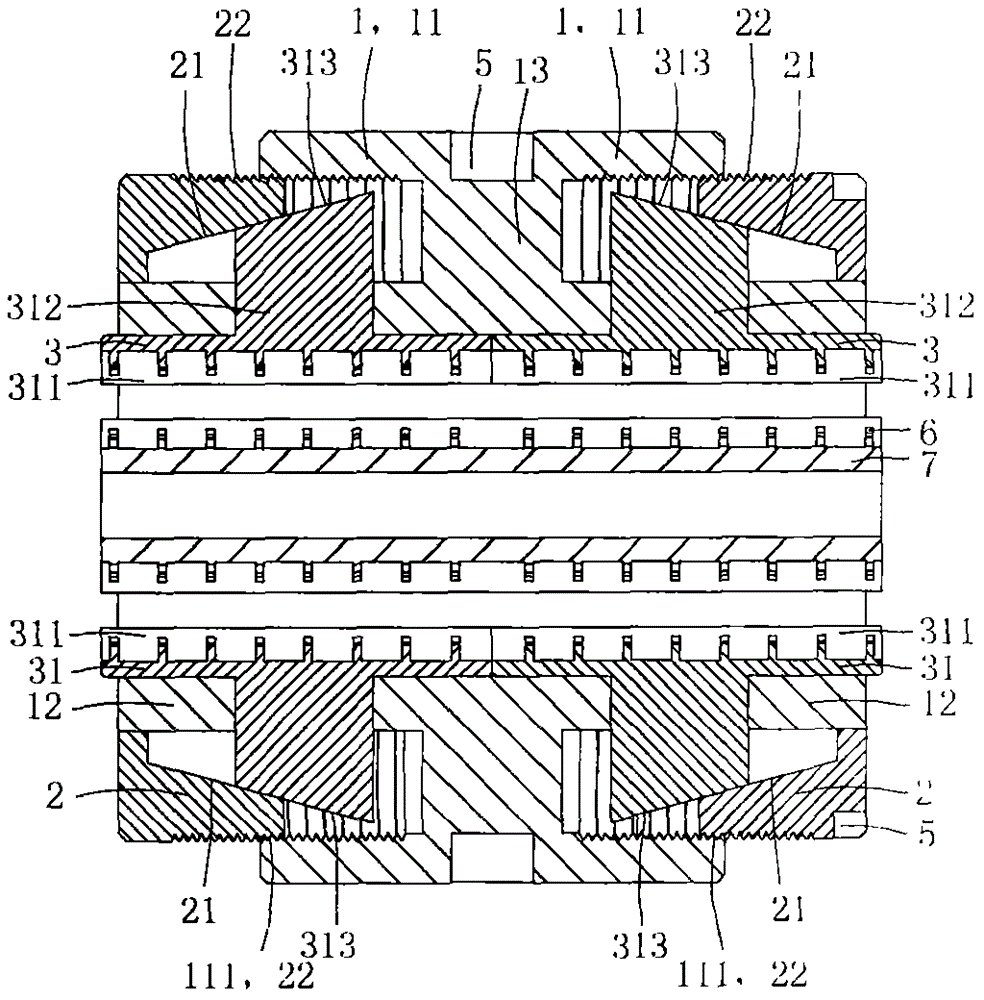

[0014] This embodiment is a high-voltage transformer that improves the clamping strength, see Figure 1 to Figure 5 As shown, it includes a base 1 , a voltage transformer 8 , two pressure rings 2 and two sets of pressure jaw assemblies 3 .

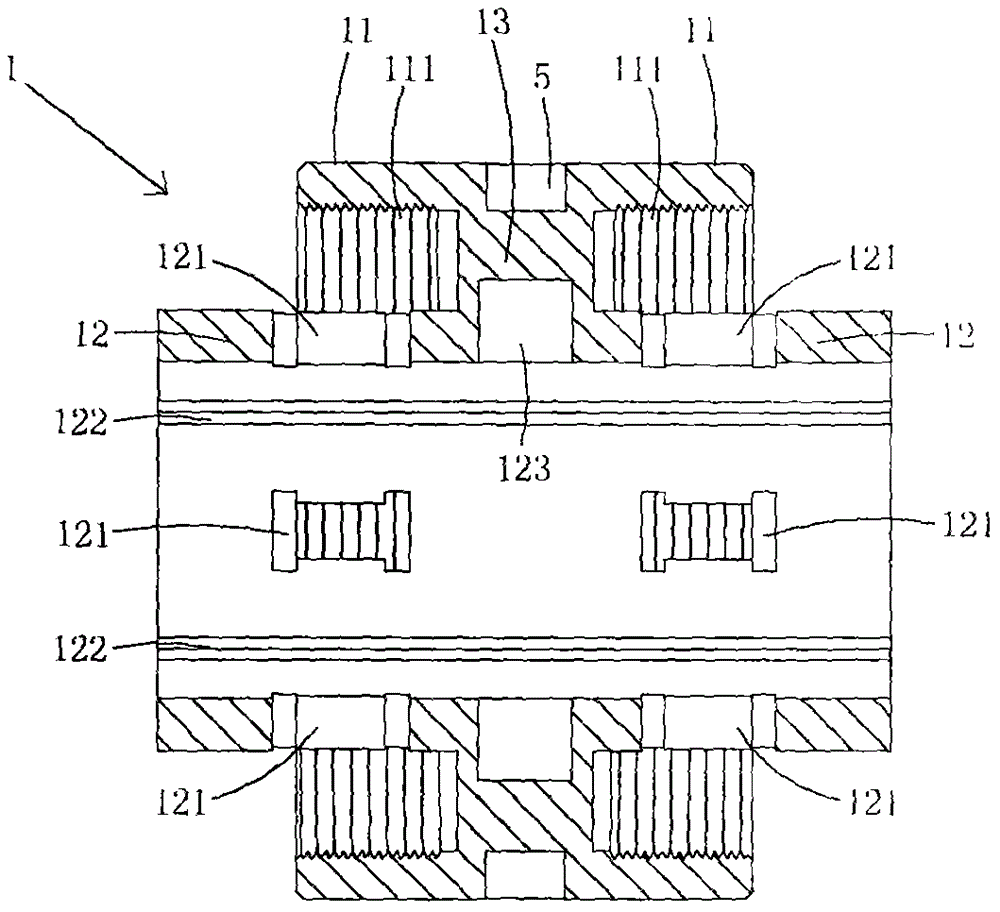

[0015] The base body 1 includes a base pipe part 11, a core pipe part 12 arranged in the lumen of the base pipe, and a connecting plate part 13 for connecting and fixing the base pipe part and the core pipe part; There is an internal thread area 1 port; the base pipe part and the core pipe part are arranged concentrically, and the connecting plate part is an annular plate located between the base pipe part and the core pipe part. In this embodiment, the connecting plate part is located between the base pipe part and the core pipe part. At the axial middle end of the pipe part, two internal thread sections are located on both sides of the connecting plate part; in practice, the structural shape of the connecting plate part only needs to mee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap