Walking mechanism, mechanical structure of line inspection robot and method for overcoming obstacles

A line inspection robot and mechanical structure technology, applied in the field of robots, can solve the problems that the obstacles of the transmission line cannot be crossed, and the continuous inspection of the ultra-high voltage transmission line cannot be realized, so as to enhance the stability, reduce the labor intensity and reduce the operation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

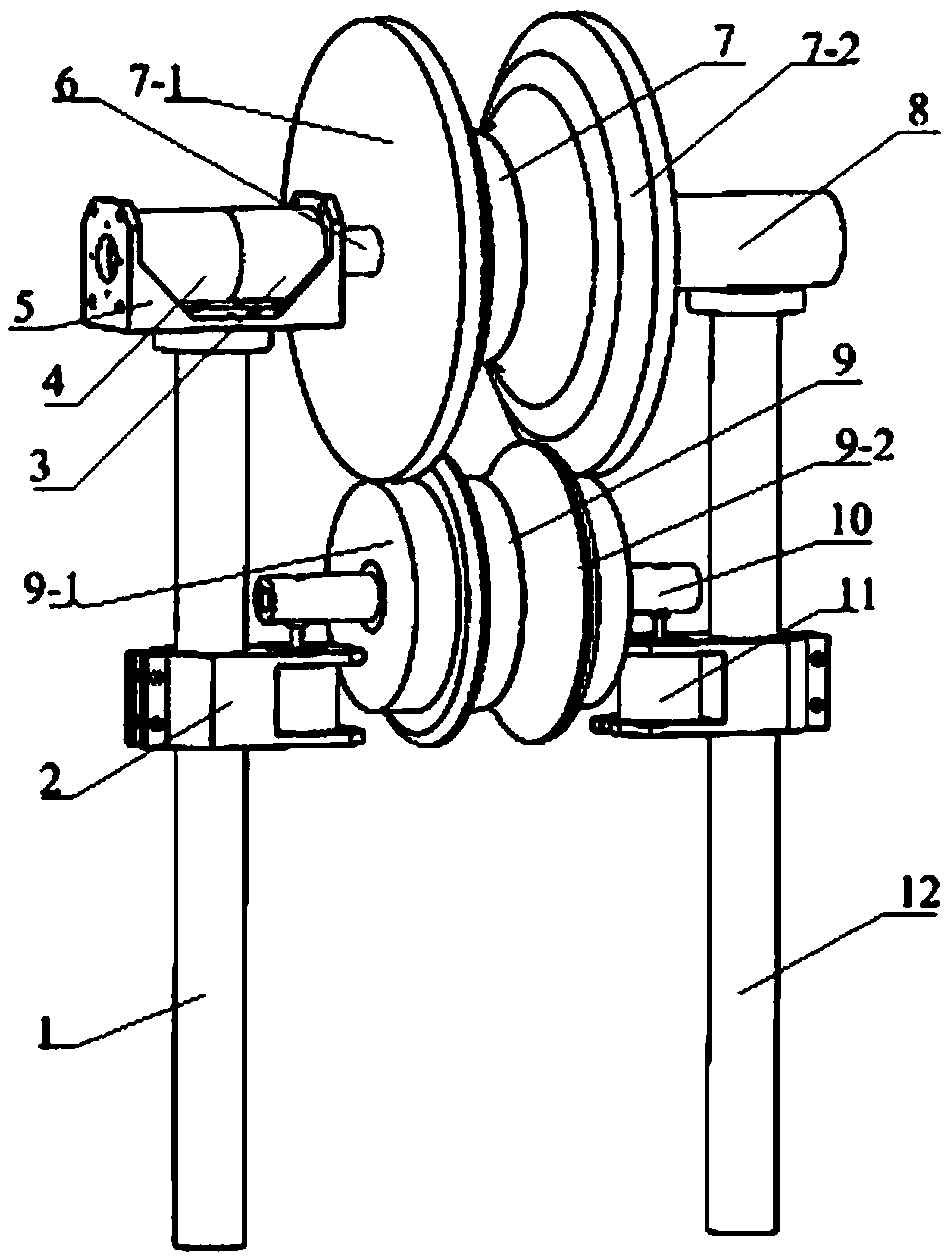

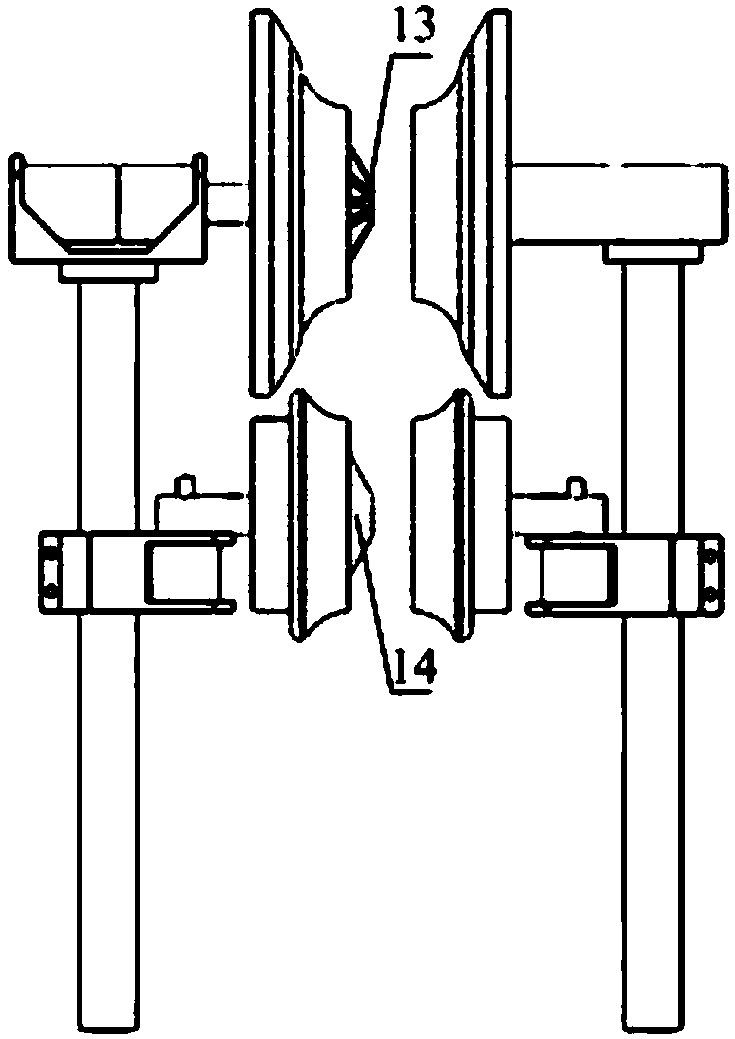

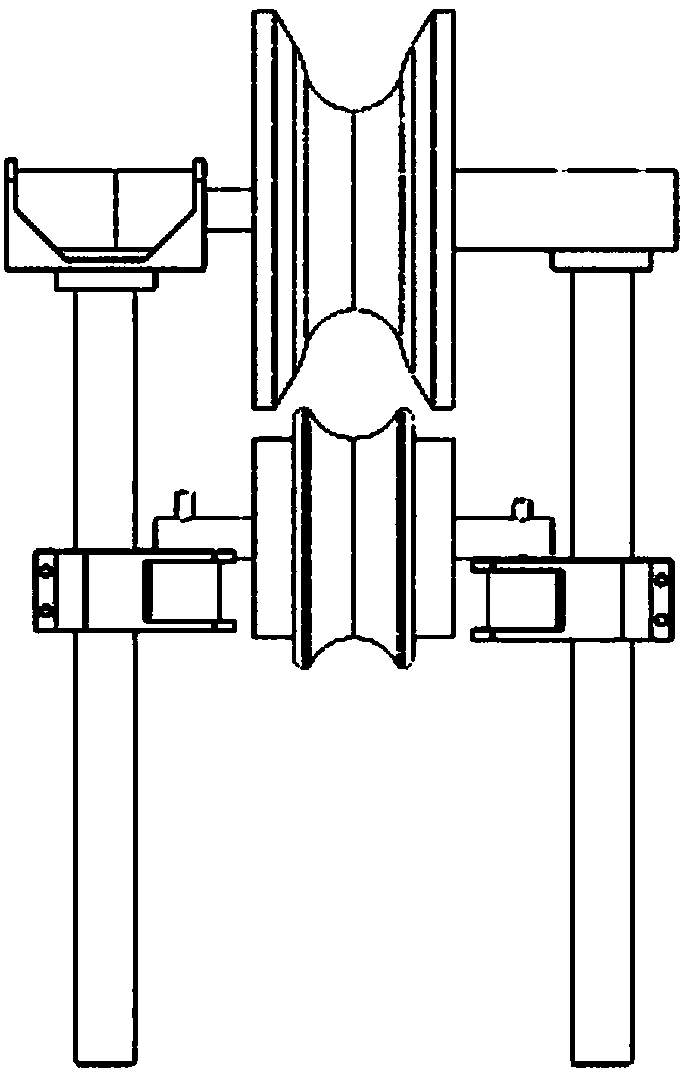

[0028] On the one hand, the present invention provides a kind of traveling wheel and clamping wheel combined traveling mechanism, such as figure 1 As shown, including at least one walking unit, wherein:

[0029] The walking unit comprises a pair of walking and splitting wheels 7, and the walking and splitting wheels 7 include an active walking and splitting wheel 7-1 and a passive walking and splitting wheel 7-2 that can be docked and separated from each other, and the active walking and splitting wheels 7-1 and A first traveling wheel arm 1 and a second traveling wheel arm 12 are arranged below the passive traveling splitting wheel 7-2;

[0030] A pair of clamping and splitting wheels 9 that can be lifted and lowered to match the clamping line are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com