Rotor structure for improving permanent magnet motor power and torque density

A technology of torque density and rotor structure, applied in the field of special motors, to achieve the effect of improving utilization, improving power and torque density, and simplifying design procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

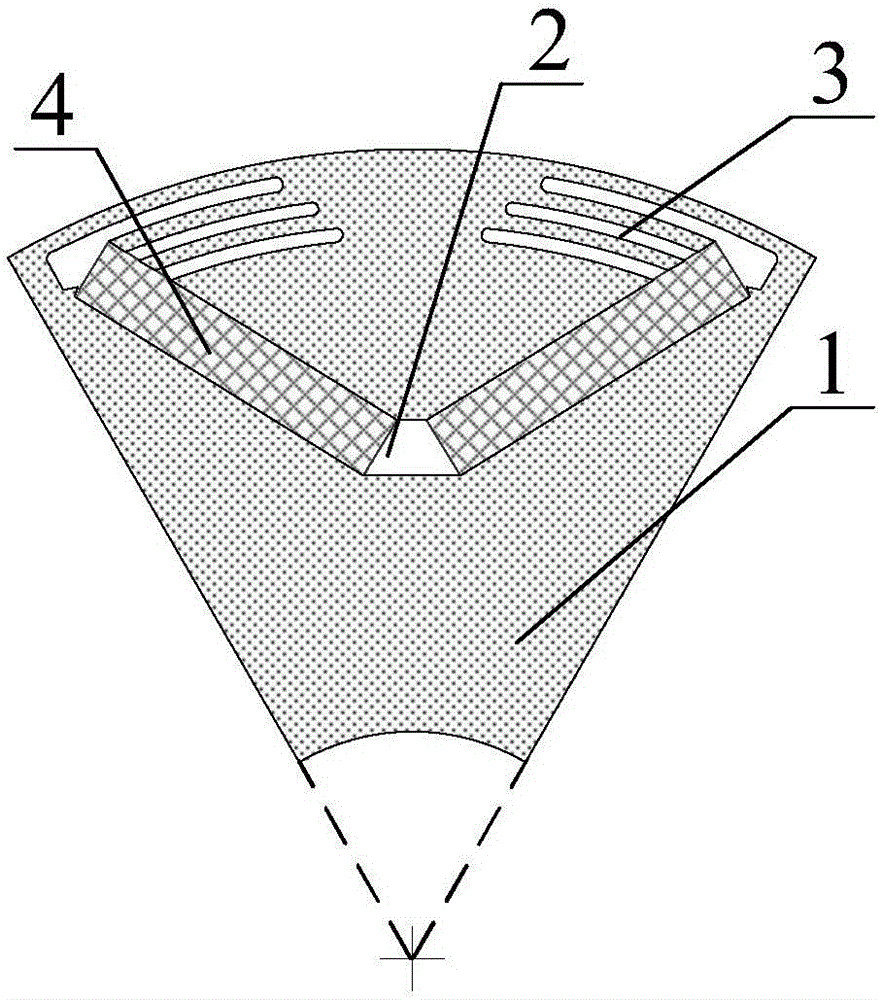

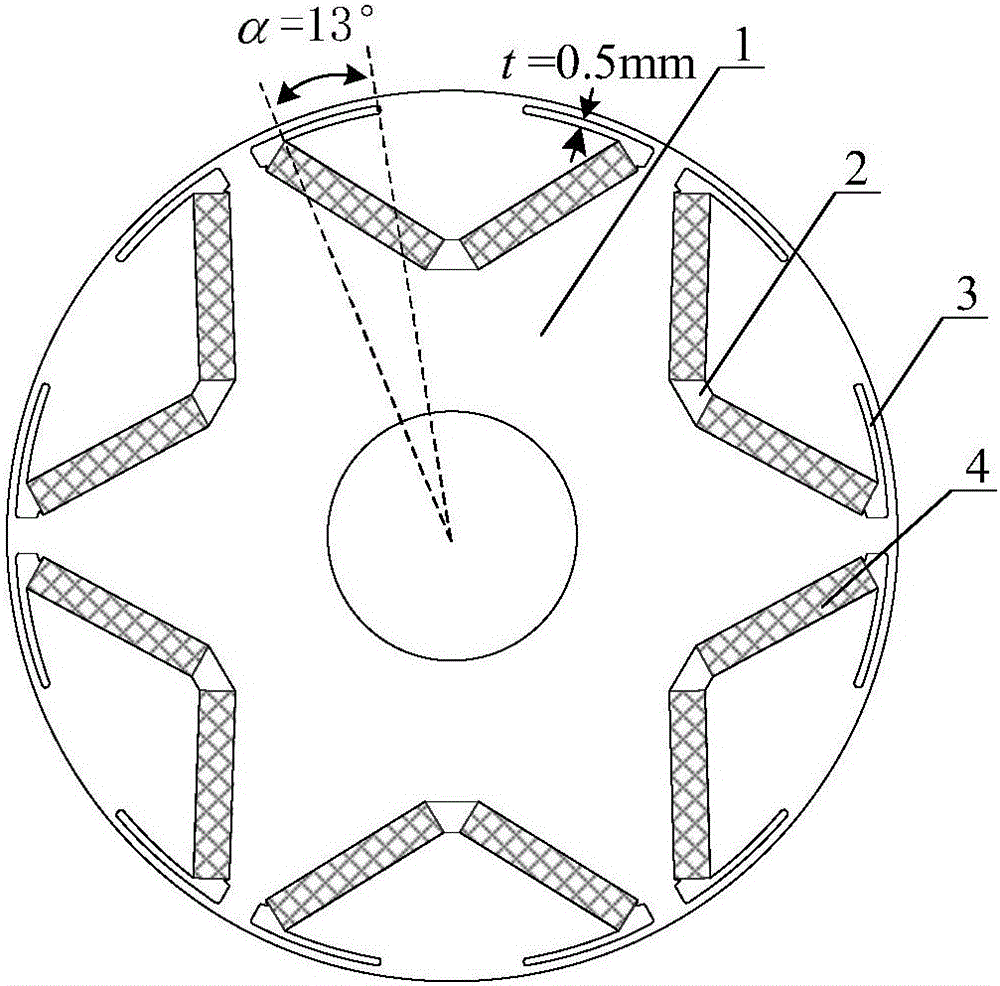

[0021] Such as figure 2 As shown, this embodiment has a structure of 6 poles and 9 slots, and adopts a centralized winding structure. The left and right tops of the permanent magnet slots 2 of the rotor 1 are each provided with a symmetrical bar-shaped slot 3 . The width of the strip groove 3 is t=0.5mm, and the angle α=13°.

Embodiment 2

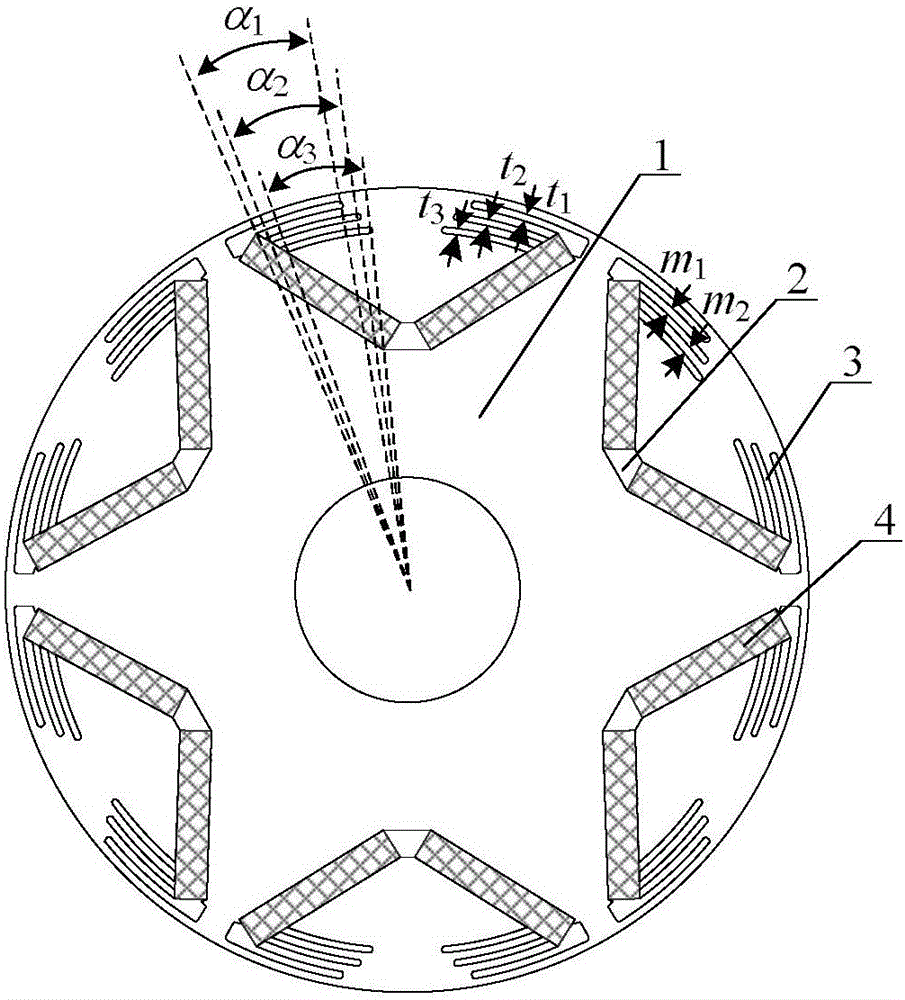

[0023] Such as image 3 As shown, this embodiment has a structure of 6 poles and 18 slots, and adopts a distributed winding structure. The left and right tops of the permanent magnet slots 2 of the rotor 1 are respectively provided with three symmetrical bar-shaped slots 3 . The width t of the strip groove 3 1 = t 2 = t 3 = 0.8mm, angle α 1 = α 2 = α 3 = 8°.

Embodiment 3

[0025] Such as Figure 4 As shown, this embodiment has a structure of 8 poles and 12 slots, and adopts a centralized winding structure. Two symmetrical bar-shaped slots 3 are respectively opened on the left and right tops of the permanent magnet slots 2 of the rotor 1 . Described strip groove 3 width t=0.6mm, angle α 1 = 5°, α 2 =7°.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap