A kind of production method of zero-added kiwi soft fruit NFC juice

A production method and technology of kiwi fruit, applied in food freezing, food science, food ultrasonic treatment, etc., can solve problems such as taste and quality impact, and achieve the effect of improving juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

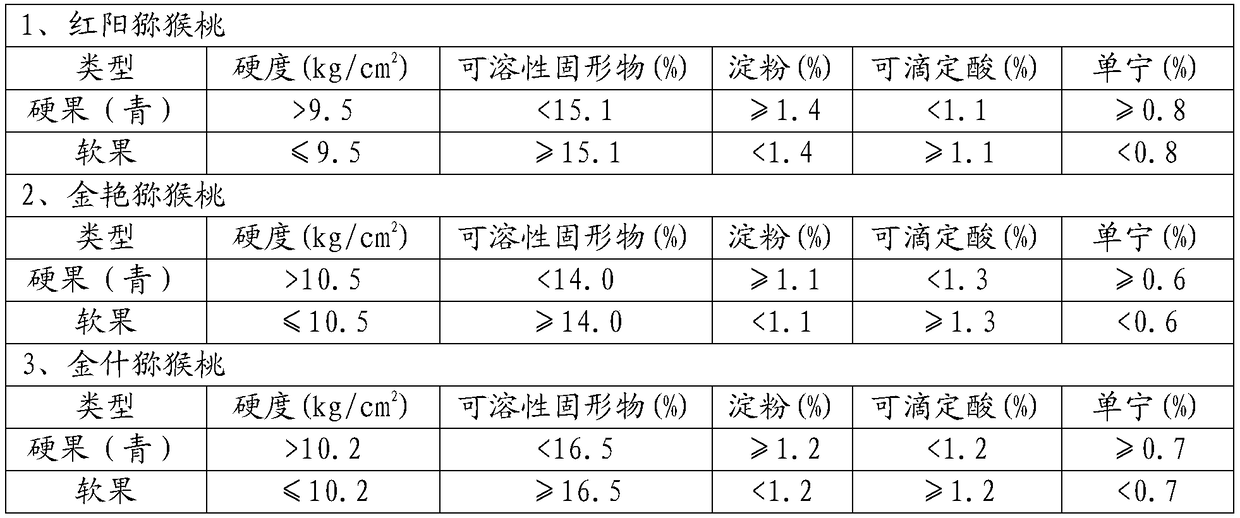

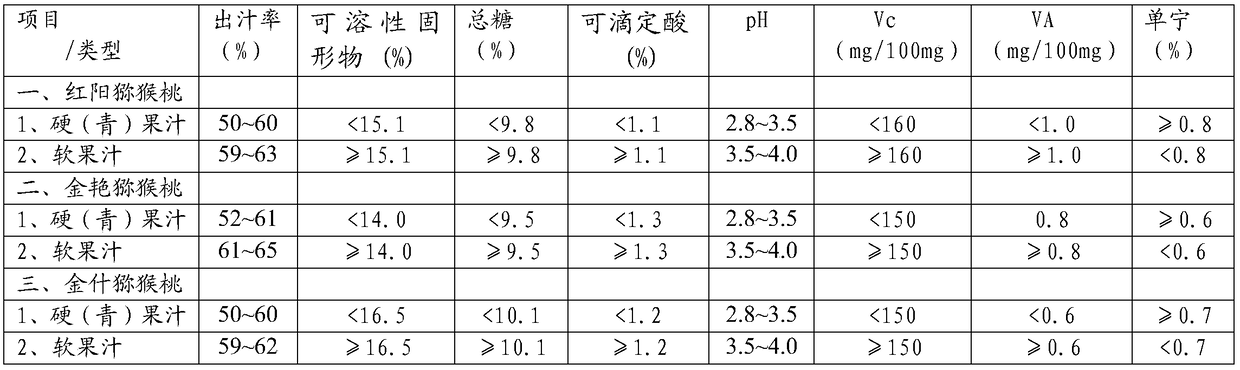

Method used

Image

Examples

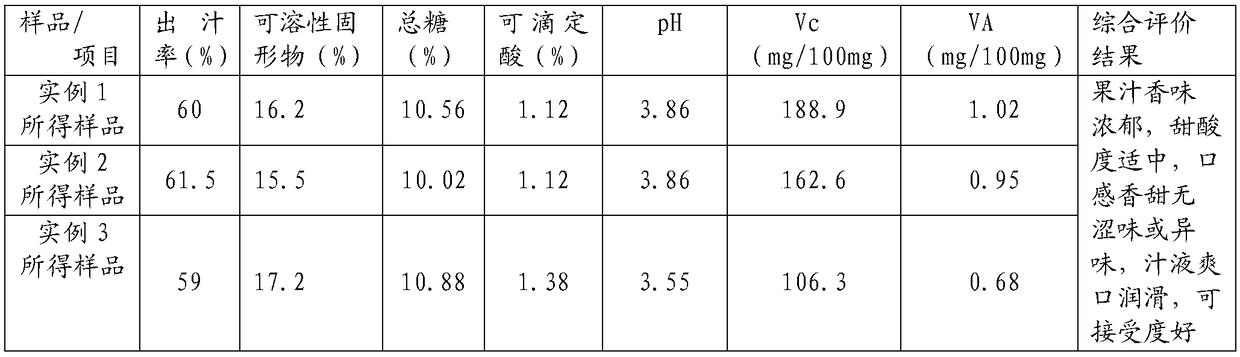

Embodiment 1

[0026] 100kg of Hongyang kiwifruit was selected, cleaned, frozen, mechanically peeled, ground, ultrasonically broken, centrifuged to extract juice, filled, and sterilized, and finally 60kg of zero-added Hongyang kiwifruit nfc juice was obtained. The specific steps are:

[0027] (1) Selection and cleaning: select fresh and graded Hongyang kiwi fruit soft fruit, remove spoiled kiwi fruit and those that do not meet the quality grade requirements; the pulp tissue is soft, no rot, mildew, and insect damage; after selection The raw fruit enters the washing machine, washes the sediment and impurities on the peel and drains;

[0028] (2) Freezing treatment: Pre-cooling + quick-freezing is used for freezing treatment. Pre-cooling parameters are: pre-cooling temperature 0 ℃, pre-cooling time 2h. The quick-freezing parameters are: the quick-freezing temperature is -12°C, and the time is 8 hours. The freezing point temperature in the center of kiwifruit reaches -3.7°C.

[0029] (3) Me...

Embodiment 2

[0035] 1000kg of Jinyan kiwifruit was selected, cleaned, frozen, mechanically peeled, ground, ultrasonically broken, centrifuged to extract juice, filled, and sterilized, and finally 615kg of zero-added Jinyan kiwifruit nfc juice was obtained. in:

[0036] (1) Selection and cleaning: Select the fresh and graded soft fruit of Jinyan kiwi fruit, and remove the rotten and degraded kiwi fruit that do not meet the quality requirements; The raw fruit enters the washing machine, washes the sediment and impurities on the peel and drains;

[0037] (2) Freezing treatment: Pre-cooling + quick-freezing is used for freezing treatment. Pre-cooling parameters are: pre-cooling temperature 2°C, pre-cooling time 3h. The quick-freezing parameters are: the quick-freezing temperature is -12°C, and the time is 6 hours. The freezing point temperature in the center of kiwifruit reaches -3.9°C.

[0038] (3) Mechanical peeling: quickly perform mechanical peeling on the frozen kiwifruit, and adjust ...

Embodiment 3

[0044]500kg of Jinshi kiwifruit was selected, cleaned, frozen, mechanically peeled, ground, ultrasonically broken, centrifuged to extract juice, filled, and sterilized, and finally 295kg of zero-added kiwifruit NFC juice was obtained. in:

[0045] (1) Selection and cleaning: Select the fresh and graded kiwi fruit soft fruit, remove the rotten and degenerate kiwi fruit that do not meet the quality grade requirements; the pulp tissue is soft, no rot, mildew, and insect damage; after selection The raw fruit enters the washing machine, washes the sediment and impurities on the peel and drains;

[0046] (2) Freezing treatment: Pre-cooling + quick-freezing is used for freezing treatment. Pre-cooling parameters are: pre-cooling temperature 1 ℃, pre-cooling time 2.5h. The quick-freezing parameters are: the quick-freezing temperature is -13°C, and the time is 7h. The freezing point temperature in the center of kiwifruit reaches -3.8°C.

[0047] (3) Mechanical peeling: quickly perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com