Filtration system and filtration method

A filter system and filter method technology, applied in the field of liquid treatment, can solve the problems of difficult cleaning of filter impurities, many valve ports, low automation control system, etc., and achieve the effect of realizing automatic control and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

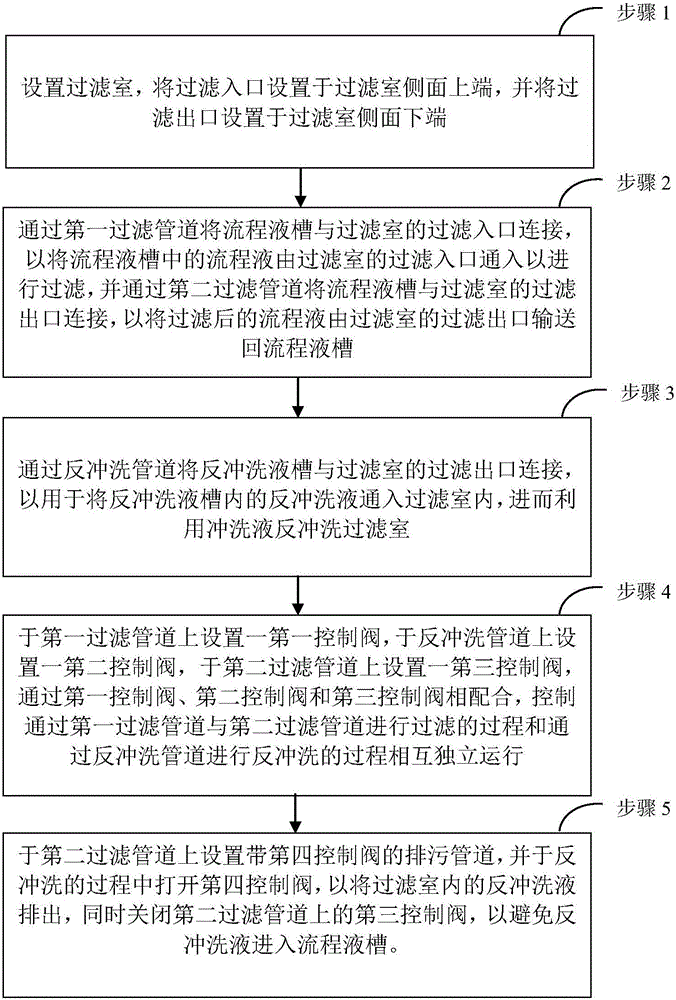

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] In the examples cited in the present invention, there is the sharing of pipelines, so the pipelines connecting various parts cannot be clearly marked, but through the description of the instructions and drawings, those skilled in the art can easily obtain the distribution mode and layout path of each pipeline And shared situation; The direction of the arrow is the determined liquid flow direction under the circumstances given by the embodiment, but it is also limited to the situation given by the embodiment. If the pipeline layout or system structure changes, the direction of the liquid flow should also change accordingly. At the same time, other modifications that do not depart from the essence and spirit of the present invention should also be considered to be included in the present invention.

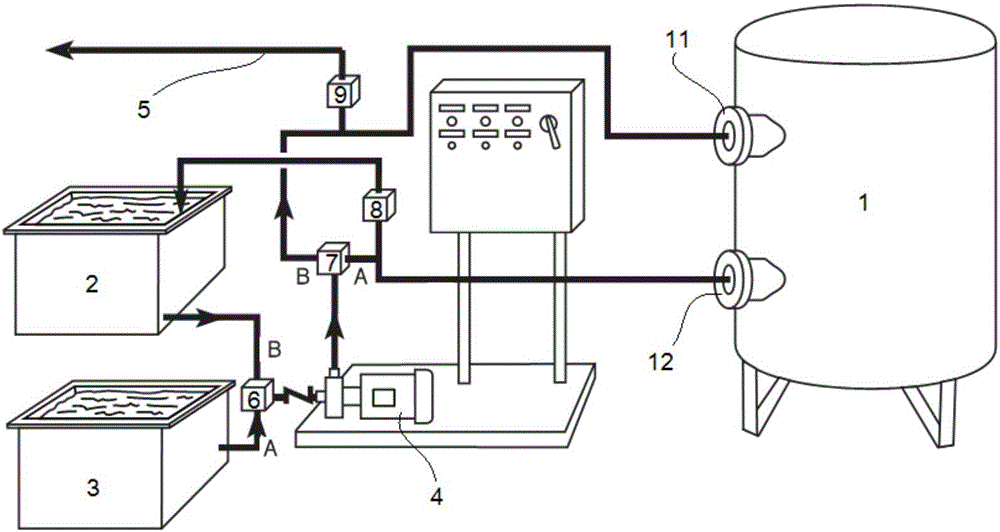

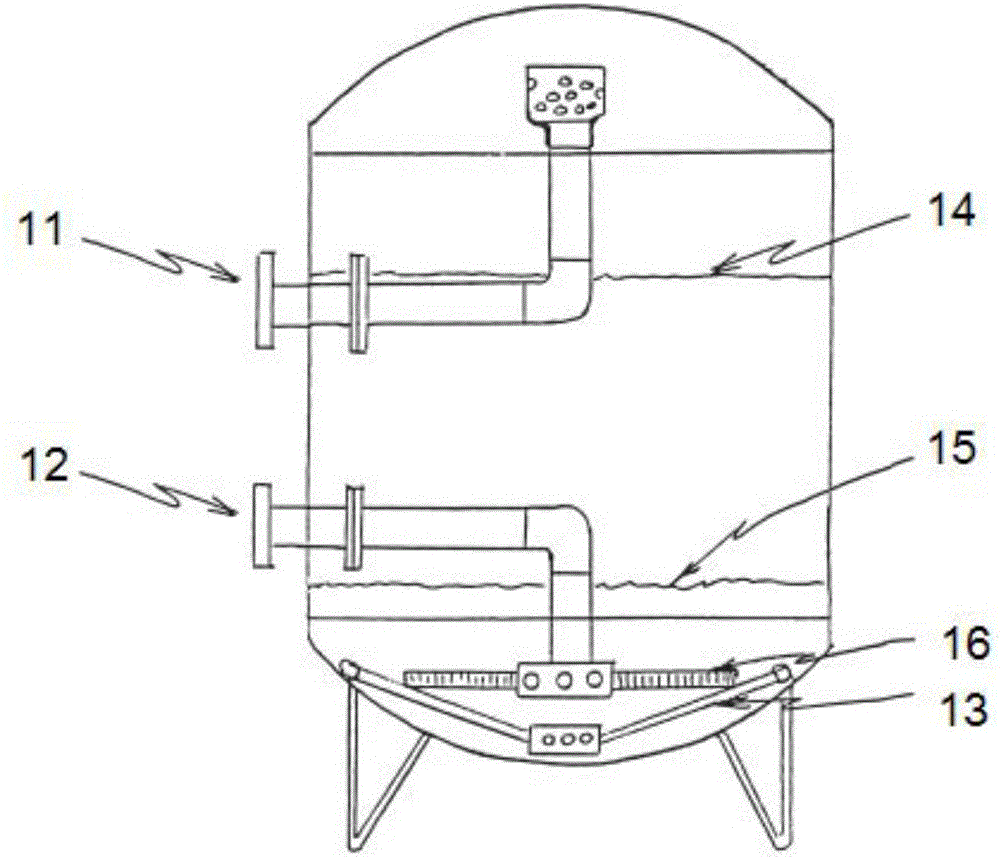

[0046] In a preferred embodiment, as figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com