Moveable type automatic dispatching and sorting electronic weigher and automatic dispatching and sorting weighing method thereof

An automatic scheduling and mobile technology, applied in sorting, weighing equipment and weighing of materials with special properties/forms, etc., can solve problems such as difficult maintenance, difficult to count the total number of actual distributions, and inconvenient movement, etc., to achieve Improve inventory management capabilities, accurate sorting and recording, and reduce manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

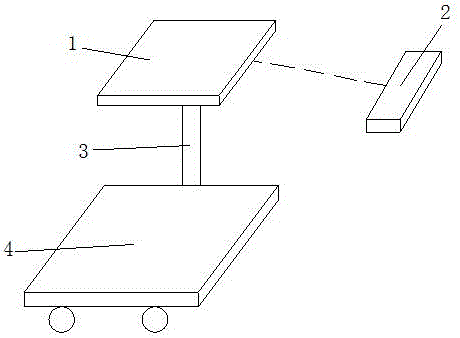

[0054] figure 1 It is a structural schematic diagram of the mobile automatic dispatching and sorting electronic scale of the present invention.

[0055] Such as figure 1 As shown, the present invention provides a mobile automatic dispatching and sorting electronic scale, comprising: an instrument 1, a code scanning device 2, a connecting rod 3 and a scale body 4; one end of the connecting rod 3 is connected with the instrument 1, and the other end is connected with the scale body 4 The code scanning device 2 is connected to the instrument 1 wirelessly.

Embodiment 2

[0057] figure 1 It is a structural schematic diagram of the mobile automatic dispatching and sorting electronic scale of the present invention.

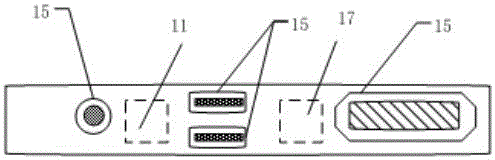

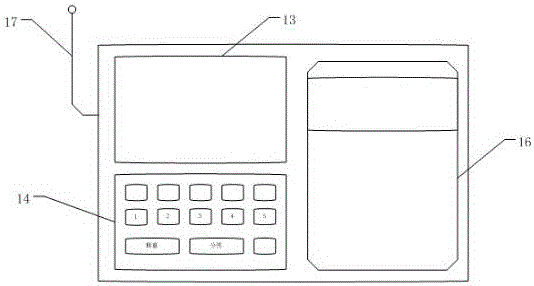

[0058] figure 2 , 3 It is a structural schematic diagram of the instrument of the present invention.

[0059] Such as Figure 1-3As shown, the present invention provides a mobile automatic dispatching and sorting electronic scale, comprising: an instrument 1, a code scanning device 2, a connecting rod 3 and a scale body 4; one end of the connecting rod 3 is connected with the instrument 1, and the other end is connected with the scale body 4 The code scanning device 2 is wirelessly connected to the instrument 1; the instrument 1 also includes: a main control unit 11, a communication module 12, a display module 13, an input module 14, an interface 15, a printer 16 and a wireless transceiver 17, and the main control unit 11 It is respectively connected with the communication module 12 , the display module 13 , the input module 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com