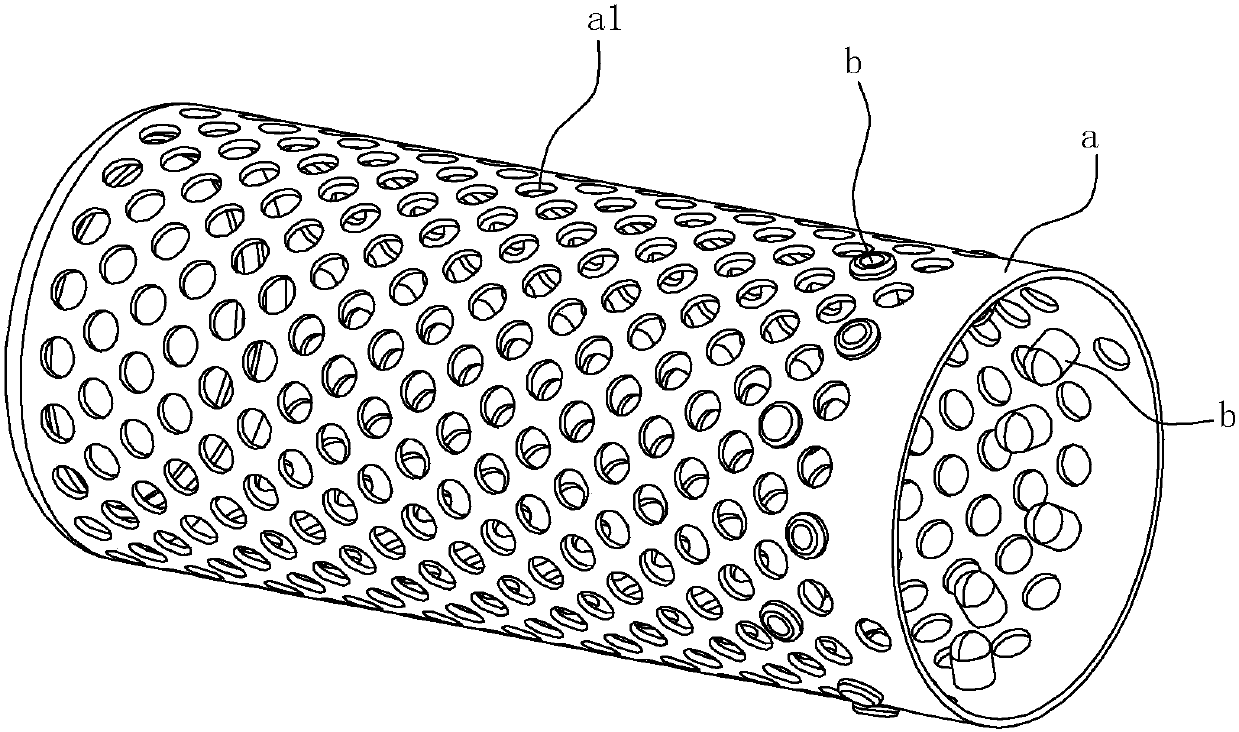

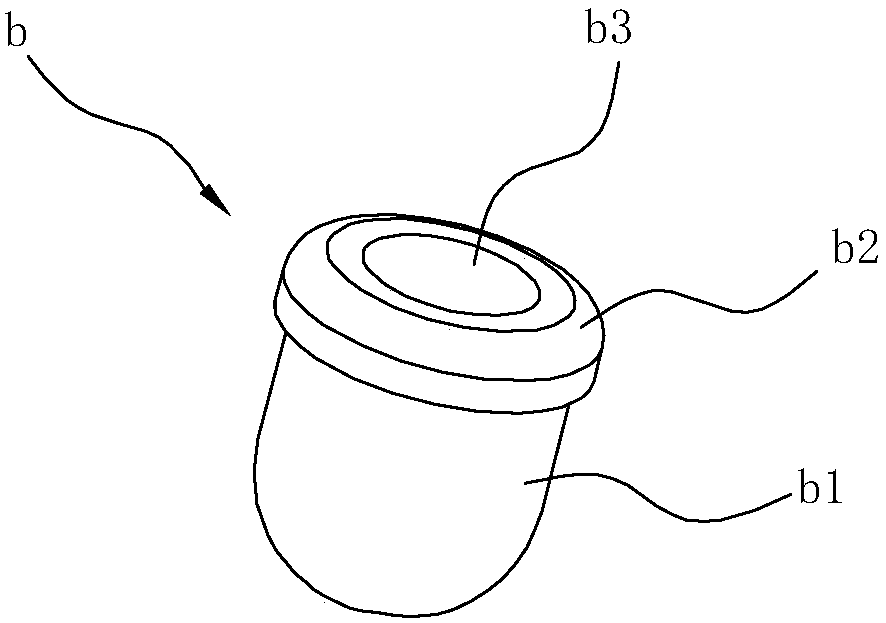

Comb handle metal cylinder planter

A metal cylinder and planting machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor product quality stability, slow artificial planting speed, and affecting comb production efficiency, so as to improve quality stability, Reduce the influence of human factors and avoid the effect of missing planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

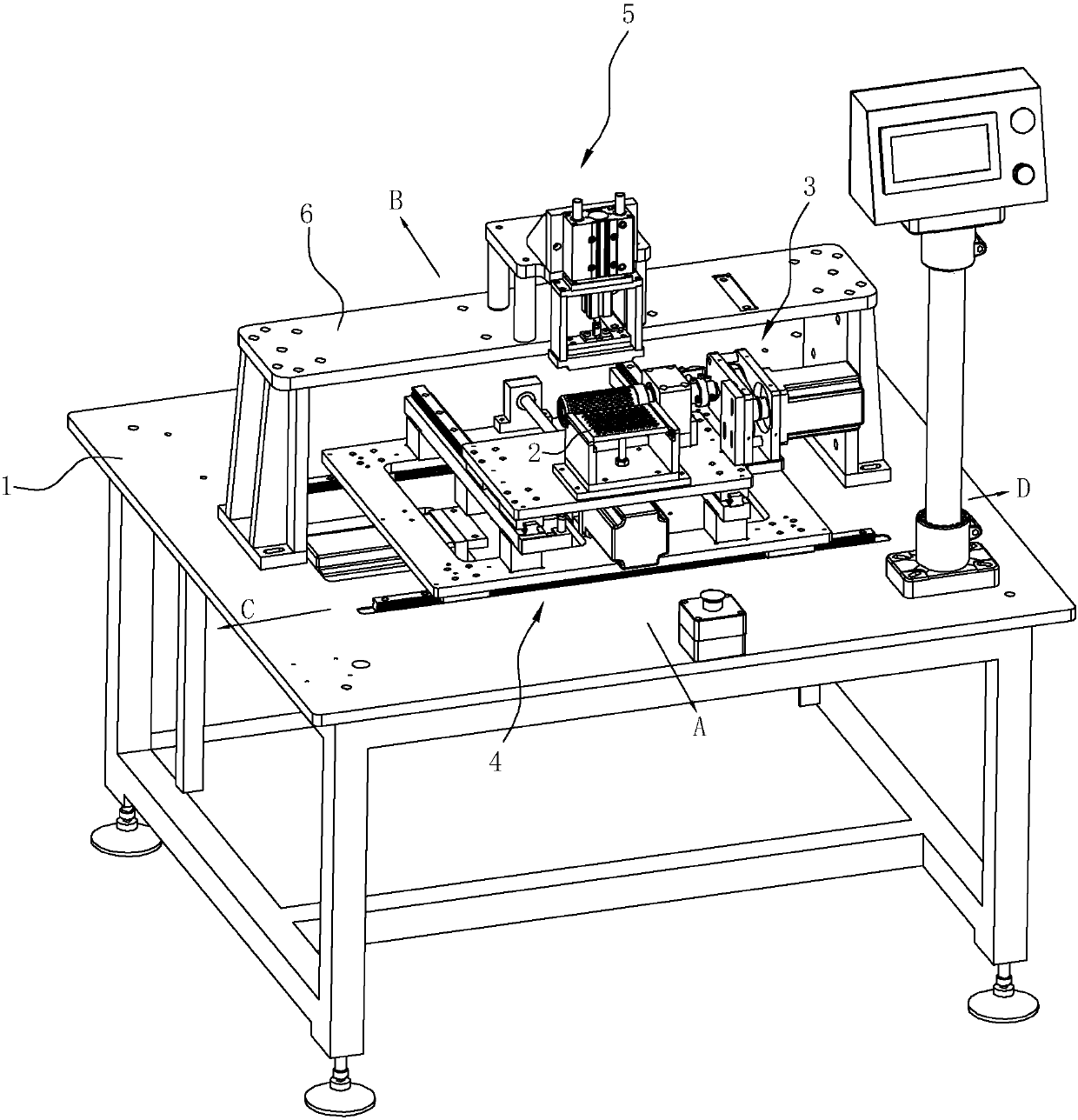

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] Such as Figure 3-9 As shown, the metal cylinder grain planter with a comb handle in this embodiment includes an operating platform 1, a hair planting particle bearing plate 2, a cylinder rotating mechanism 3, a position adjustment mechanism 4 and a hair planting particle transfer mechanism 5. In this example, with image 3 The A direction is the front, the B direction is the rear, the C direction is the left, and the D direction is the right.

[0033]The grain planting work of the present embodiment is completed on the operating platform 1 . The operating platform 1 is provided with a first supporting plate 11 capable of moving back and forth and left and right on the operating platform 1 , and the first supporting plate 11 is set on the operating platform 1 through the position adjustment mechanism 4 and can move forward and backwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com