Elevation type bus chairs

A bus, lift-type technology, applied in vehicle seats, movable seats, bus seats, etc., can solve the problems of increasing passengers, waste of resources, and tired passengers, and achieve the effect of convenient, safe and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described now in conjunction with accompanying drawing.

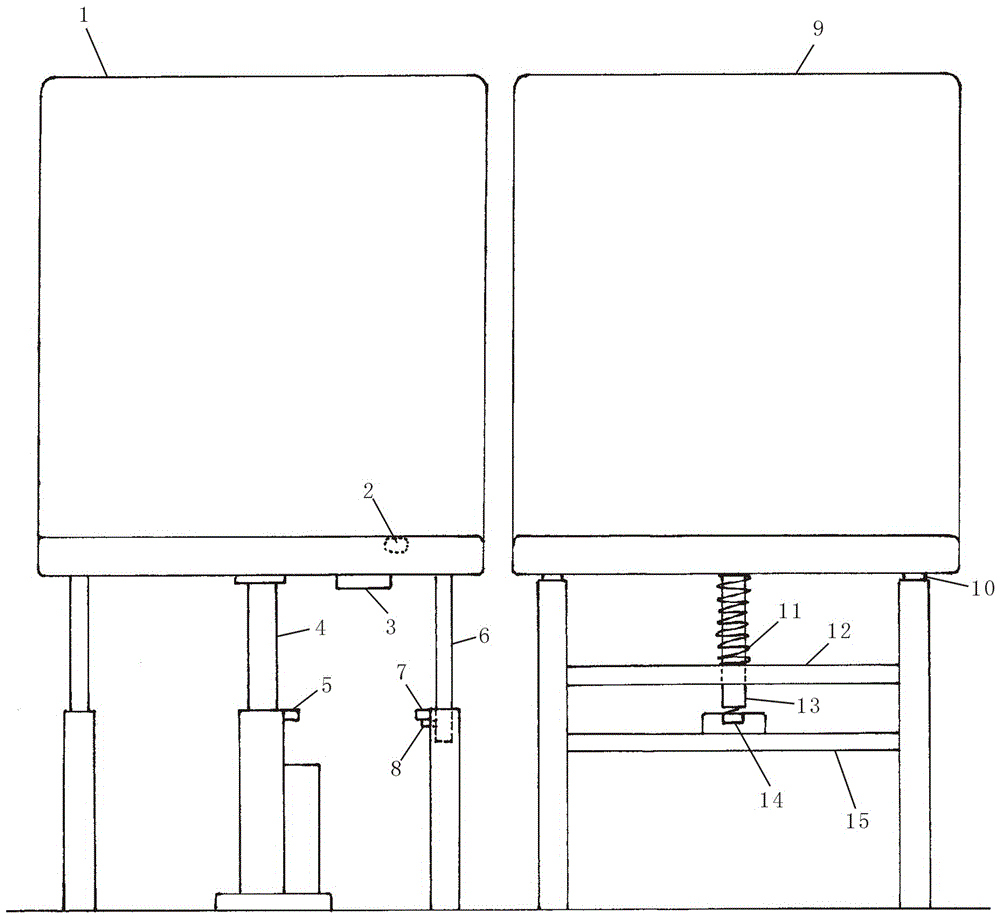

[0010] like figure 1 As shown in the figure, 1. Outside chair, 2. Sensor, 3. Controller, 4. Piston rod, 5. First switch, 6. Lifting rod, 7. Second switch, 8. Touch key, 9. Inside Chair, 10. Shaft, 11. Spring, 12. Upper rail, 13. Vertical bar, 14. Micro switch, 15. Lower rail.

[0011] The chairs refer to two chairs arranged in the same row on the bus that are very close to each other, i.e. the outer chair 1 and the inner chair 9; the outer chair 1 is provided with an electric vertical directional hydraulic device, the bottom of the oil cylinder of the hydraulic device is connected with the floor in the bus, and the top of the piston rod 4 of the hydraulic device is connected with the seat board of the outer chair 1, that is, the first seat board; the oil cylinder is provided with a limit position The first switch 5 that acts, the first switch 5 corresponds to the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com