High-precision automatic material grabbing system with storage location and wagon

A high-precision, material truck technology, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems that affect product quality, serious time-consuming, grasping failure, etc., to improve safety and operating efficiency, improve The effect of working accuracy and reducing human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

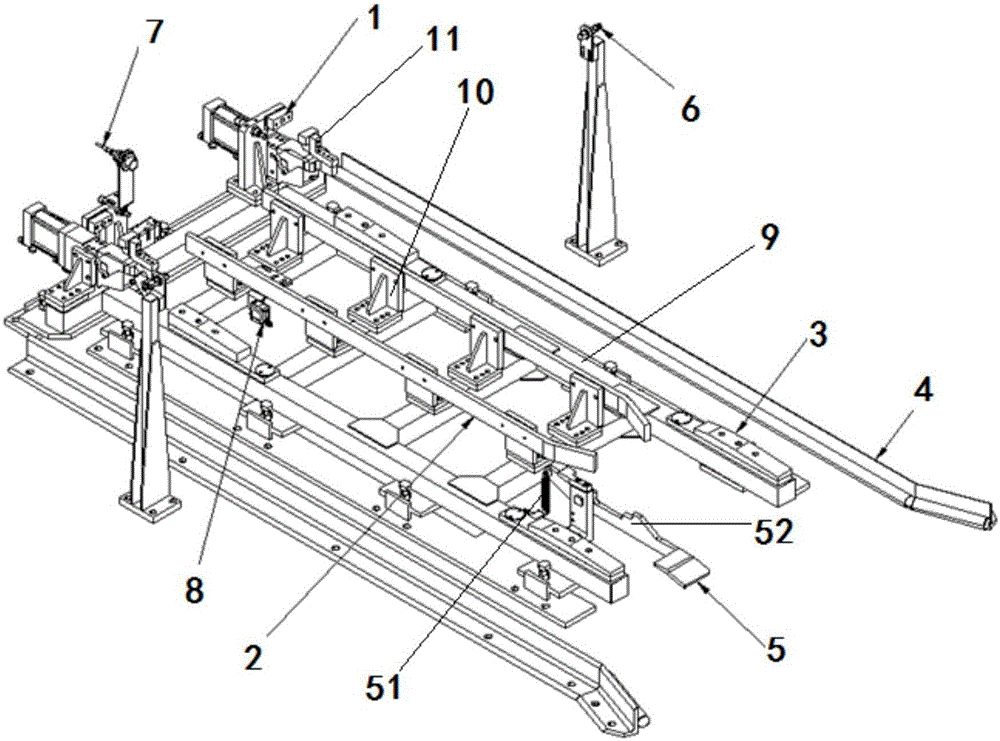

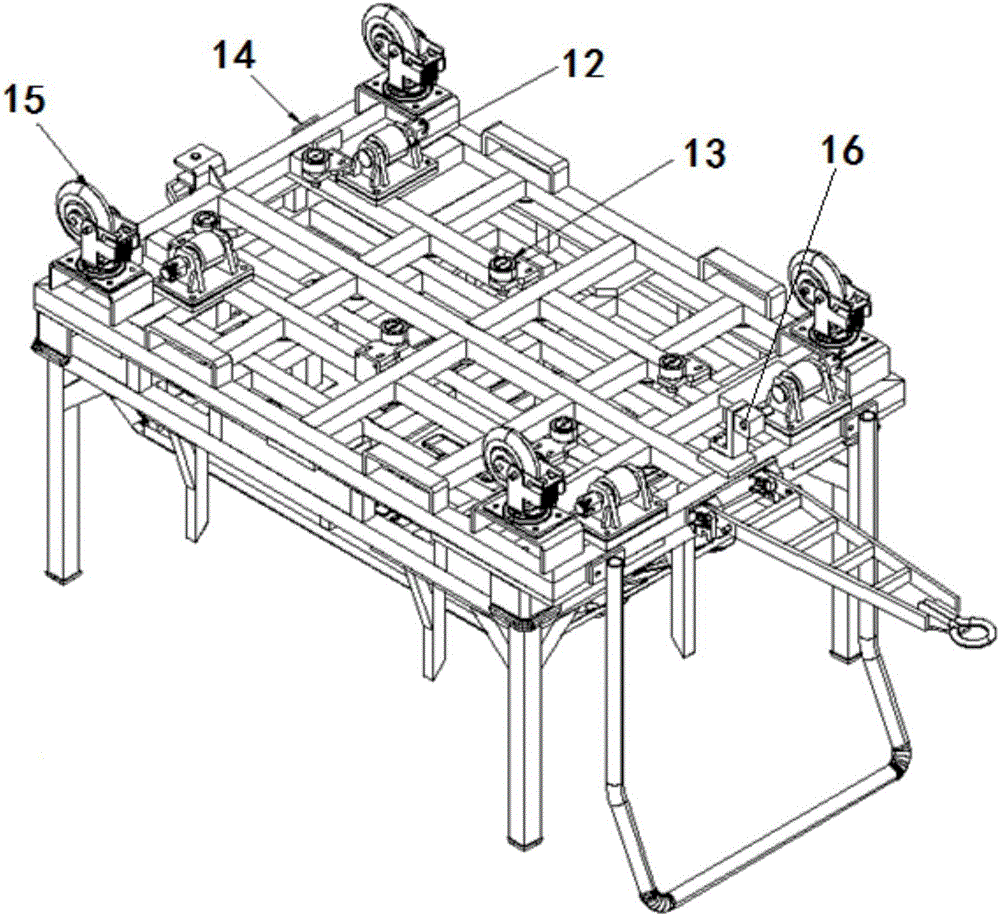

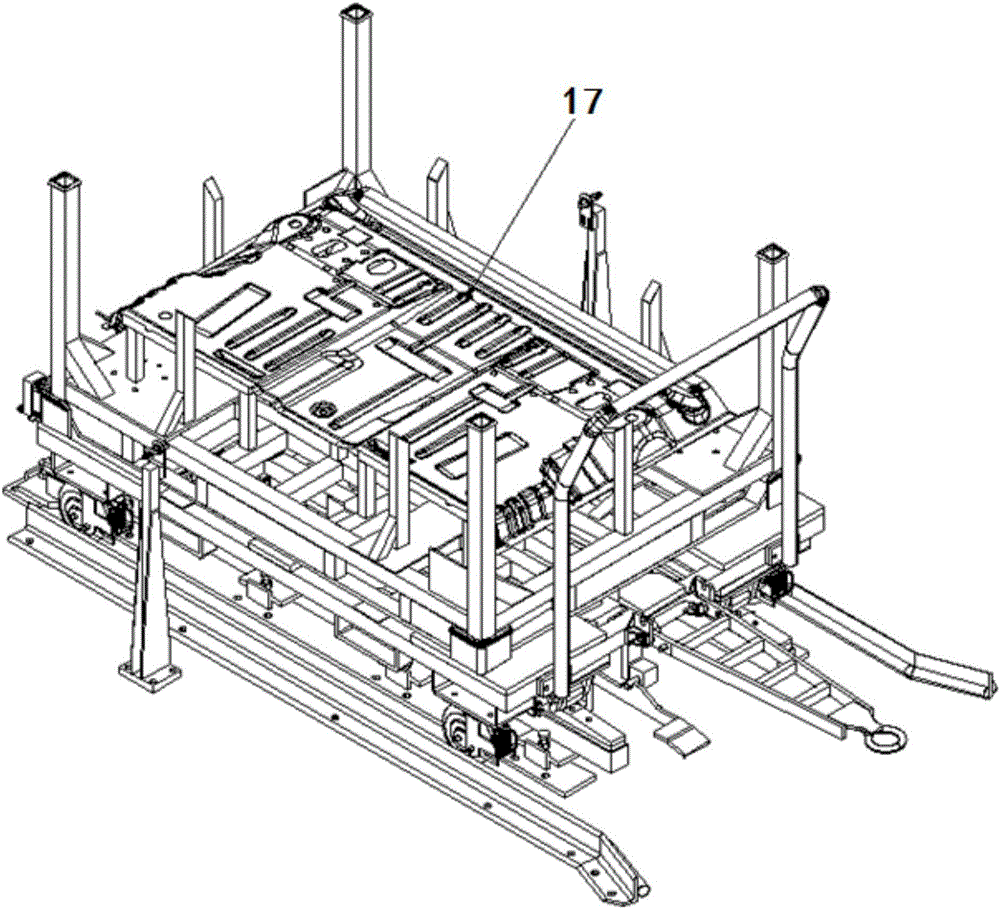

[0023] A high-precision warehouse location and material truck automatic grabbing system, including the warehouse location and material truck. where the location structure is as follows figure 1 As shown, the storage location includes positioning platform 9, X positioning reference plate 1, Y positioning reference guide rail 2, Z positioning reference table 3, rough orientation guide rail 4, foot brake 5, through-beam sensor 6, vehicle type sensor 7 and diffuse reflection sensor 8. Wherein, the positioning platform 9 is located at the center of the storage position, and is mainly used for the positioning of the material truck, the X positioning reference plate 1 is located at the front end of the positioning platform 9, and the Z positioning reference platform 3 includes 4 ladders evenly distributed on both sides of the positioning platform 9 , The Y positioning reference guide rail 2 includes two parallel guide rails, the two parallel guide rails are connected to the position...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap