Automatic drawing-penetrating shaft and adapting structure of winding machine

A technology for adapting structures and winding machines, which is applied in the directions of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems that equipment cannot be automatically adapted, cannot meet production needs, and has a low degree of automation. Simple and reasonable, easy to realize, low work intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

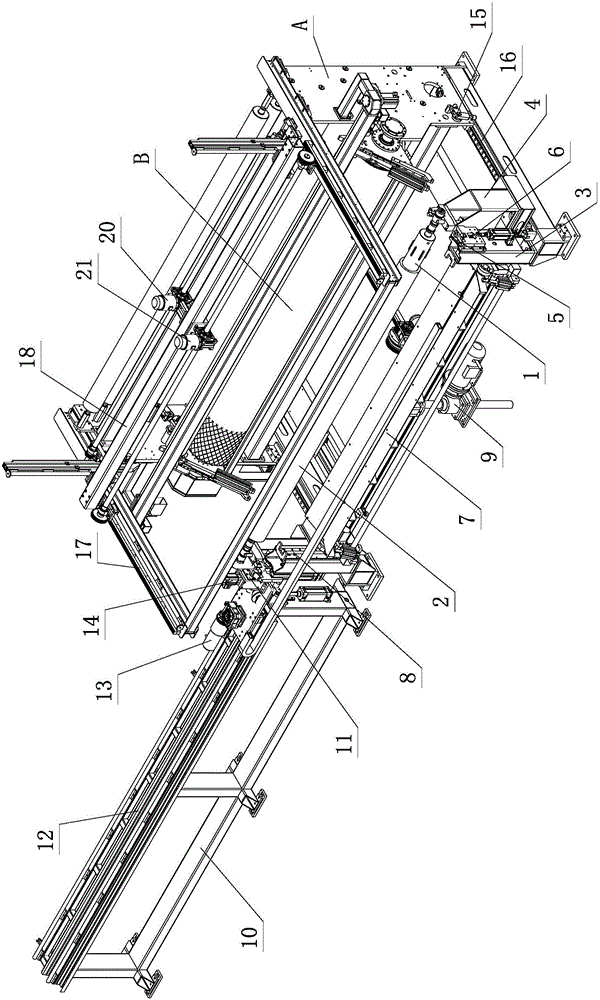

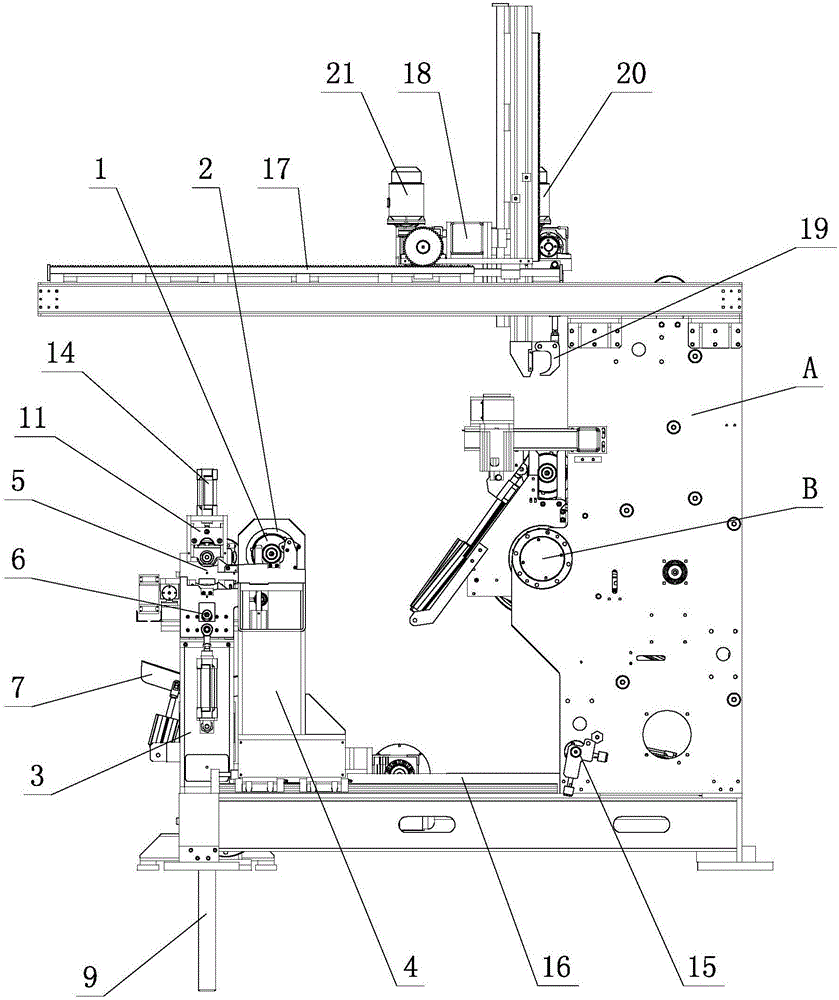

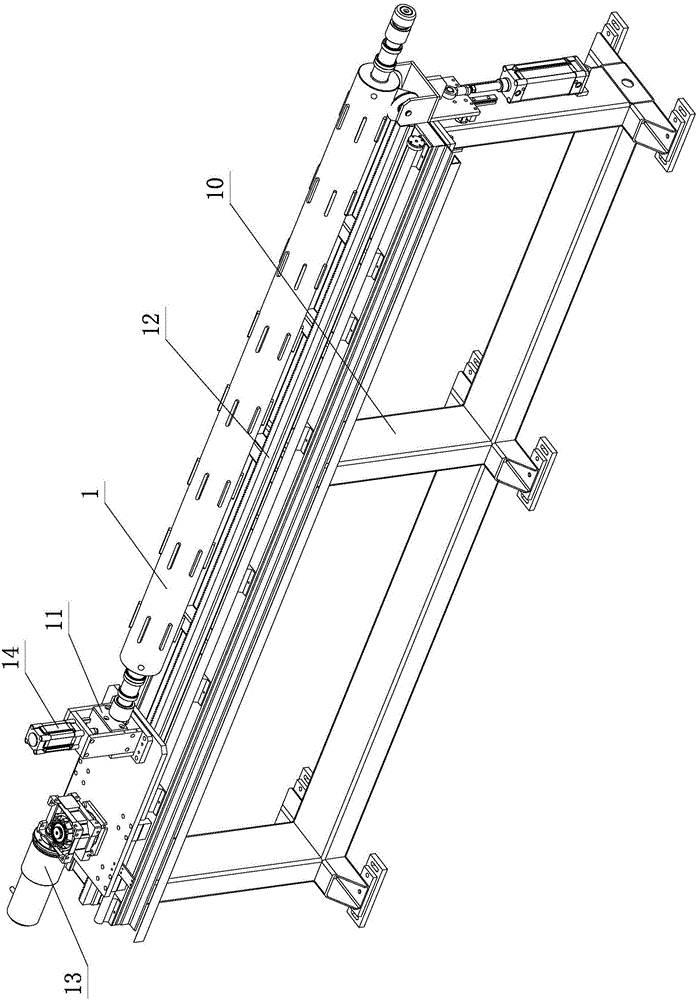

[0019] see Figure 1-Figure 3 , the automatic pull-through shaft and the matching structure of the winder include the main body A of the winder, and the main body A of the winder is provided with an air expansion shaft 1, a winding shaft 2, a winding device B, a conveying device, and an air expansion shaft Threading and pumping device, tray bracket 3 and winding trolley 4; the winding shaft 2 is sleeved on the inflatable shaft 1 at least when rolling the film, and the two move between the winding trolley 4 and the tray bracket 3 through the conveying device; Among them, the tray bracket 3 is provided with a proximity switch 5 and a limit switch 6. The air shaft 1 is automatically pulled away from the winding shaft 2 through the cooperation of the air shaft threading device and the proximity switch 5. The cooperation of the shaft threading device and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com