Elevator system against accidental movement

An elevator system and unexpected movement technology, applied in the elevator field, can solve the problems of slow reaction speed, difficult to pull out, complex structure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

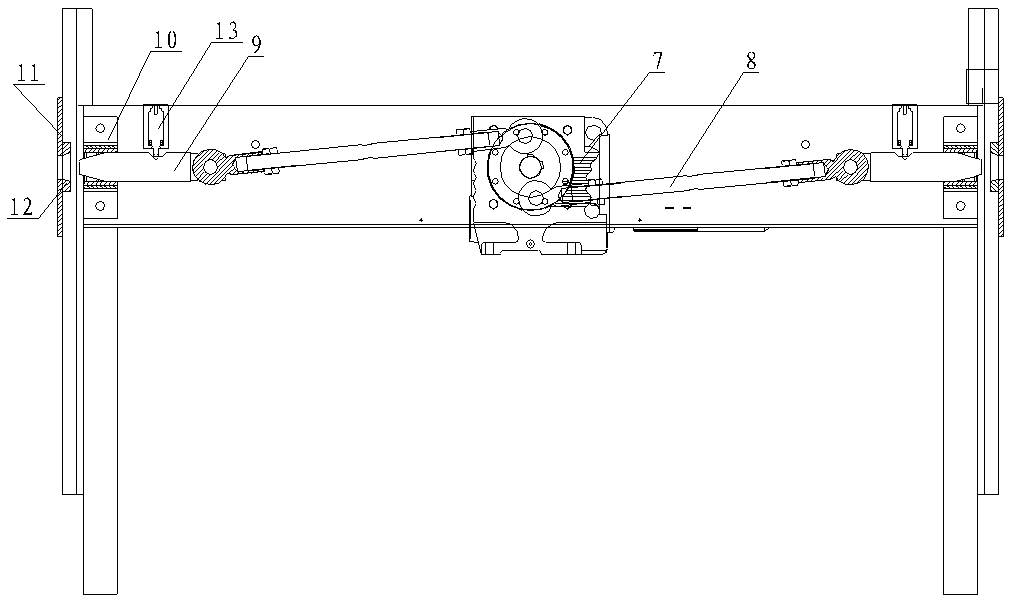

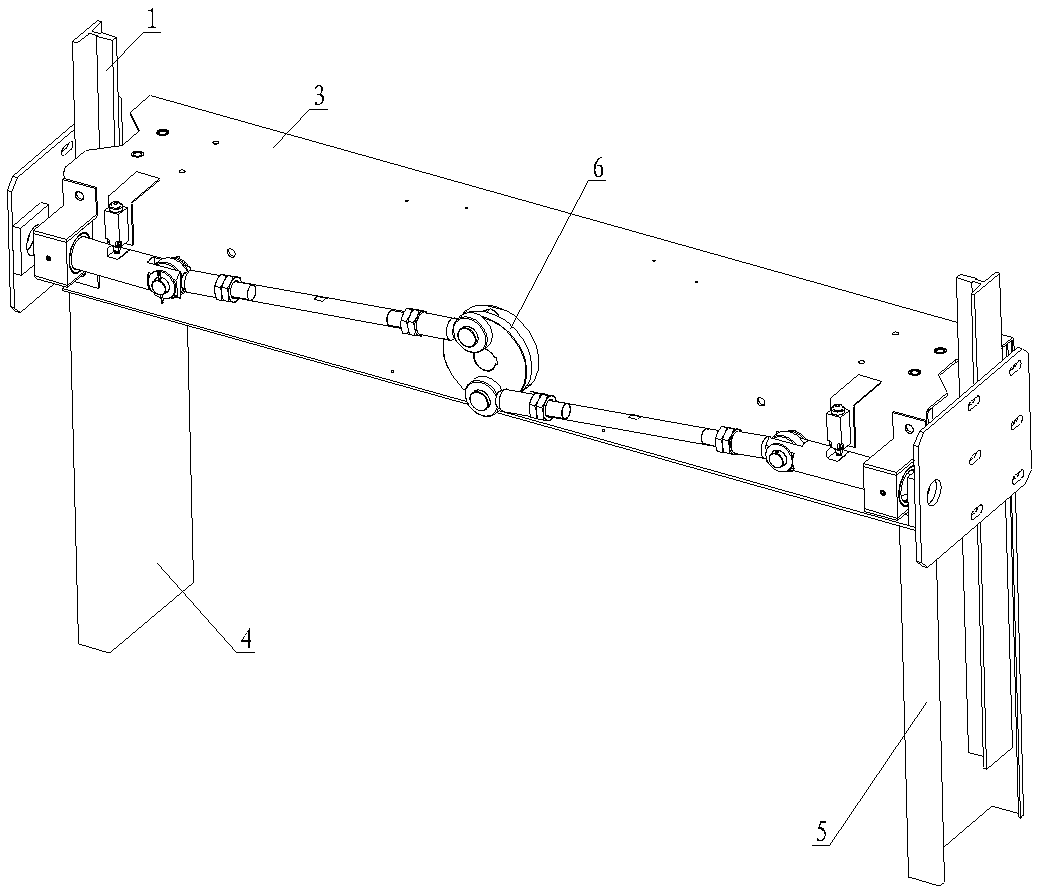

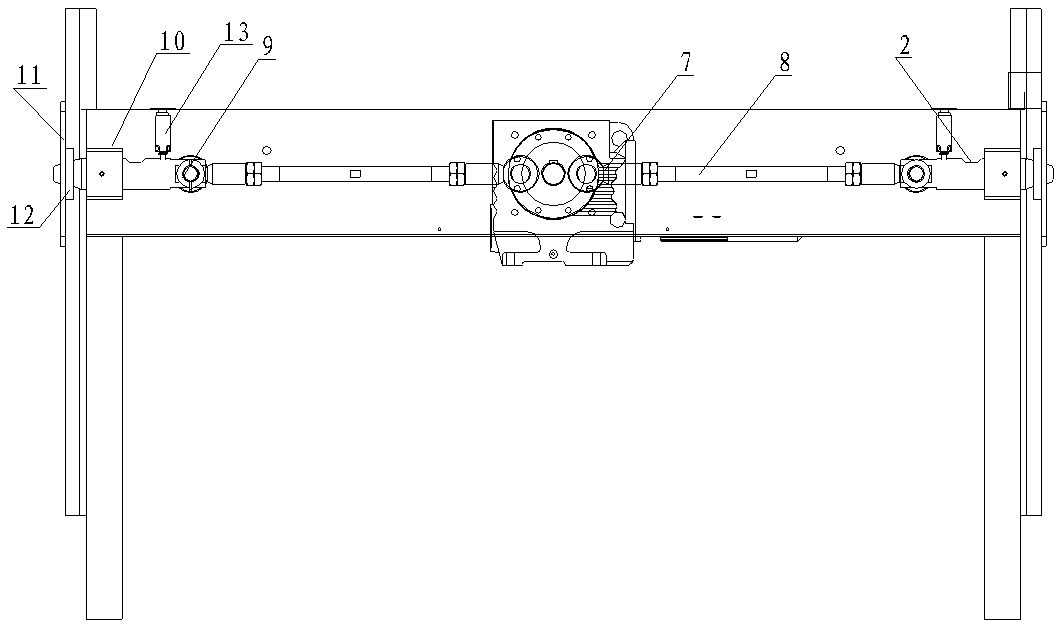

[0016] An embodiment of an elevator system that prevents accidental movement, in Figure 1-Figure 5 Among them, there are two guide rails 1, which are respectively used to be assembled in the hoistway. A car is slidably arranged on the guide rail 1, and a beam 3 is arranged on the upper and lower parts of the car. 4 and the right vertical beam 5, two crossbeams 3 and the left vertical beam 4 and the right vertical beam 5 form a frame shape, the car is in this frame, the crossbeam 3 is directly connected with the steel wire rope, and the above structure is a conventional one in the prior art structure, a flange turntable 6 is installed on the upper beam 3, and a motor is fixedly installed on the beam 3. The output shaft of the motor is equipped with a parking brake device, which will stop the motor when the motor stops. Locking, this type of motor belongs to the commercially available parts, the motor is connected with the flange turntable 6 through the reducer 7, drives the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com