Hoist fastening tool

A fastening and tooling technology, which is applied in the field of building material hoisting, can solve the problems of difficult reuse and huge waste of labor costs, and achieve the effects of ensuring strength, improving stability and service life, and reducing swing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

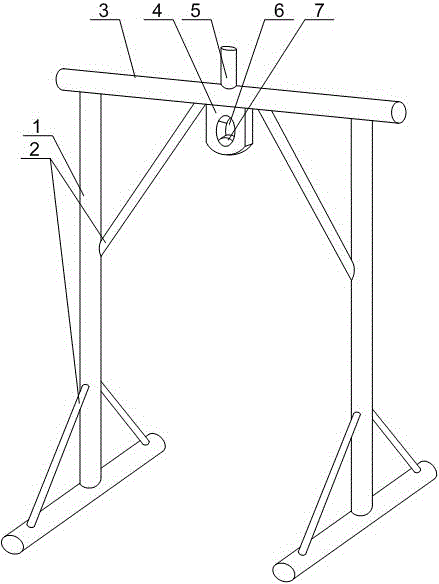

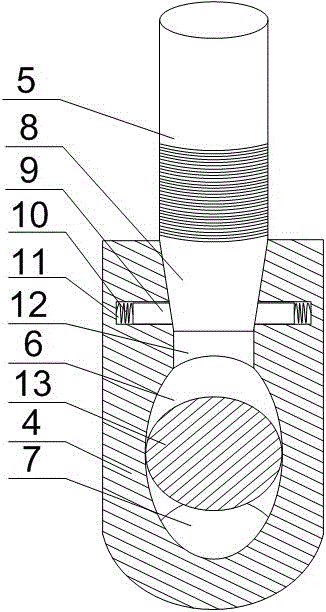

[0023] Such as figure 1 with figure 2 As shown, this embodiment includes a crossbar 3 and two T-shaped support arms 1, the crossbar 3 is welded on the top of the vertical section of the two support arms 1, and a hanging plate 4 is installed at the bottom of the crossbar 3 , the hanging plate 4 is provided with connecting holes 6 and through holes which communicate with each other and the axes are perpendicular to each other, and also includes an adjusting rod 5, the lower section of the adjusting rod 5 moves through the cross bar 3, the through hole in turn and moves toward the connecting hole. 6 extends inwardly, and thread is provided on the outer wall of the lower section of the adjustment rod 5, and the adjustment rod 5 is threadedly matched with the cross bar 3, and the lower end of the adjustment rod 5 is connected with a lower pressing block 12 through a universal head.

[0024] Two T-shaped support arms 1 are formed by welding the remaining building materials in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com