A car door sealing structure and optimization design method

A technology of sealing structure and optimized design, applied in sealing devices, engine sealing, door devices, etc., can solve the problems of reduced door sealing performance and service life, fatigue aging of seals, uneven stress on seals, etc. The effect of reducing frequency and amplitude, improving sealing performance and service life, and reducing oscillation frequency and amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

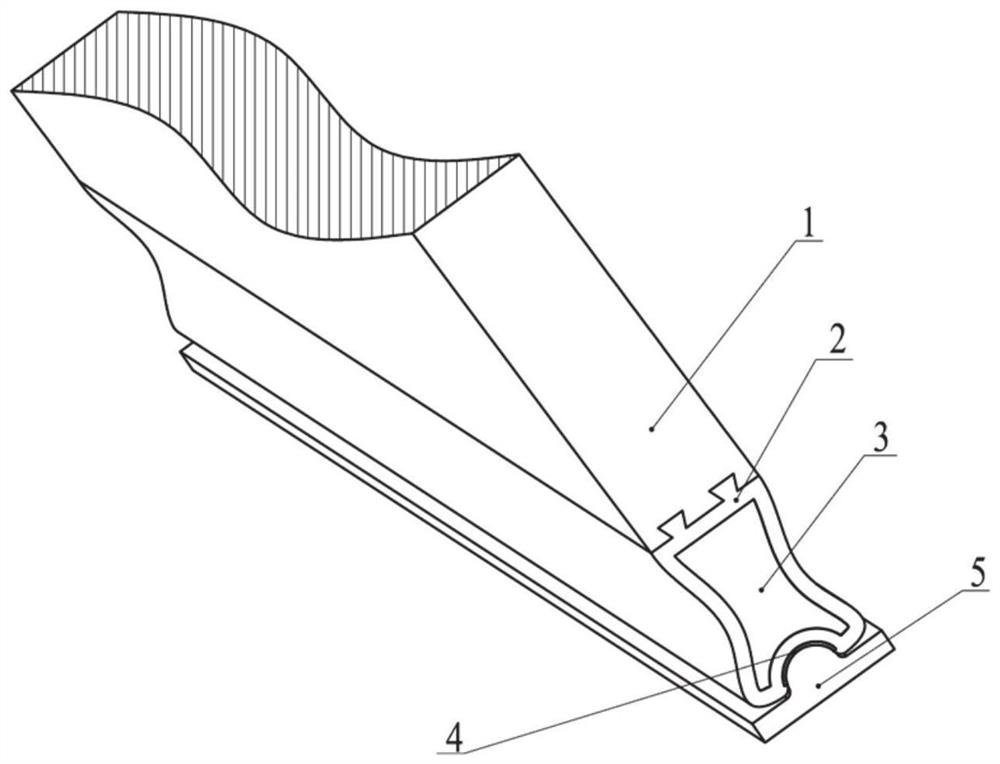

[0036] According to an embodiment of the present invention, an embodiment of a vehicle door sealing structure is provided, referring to figure 1 , comprising: a sealing element arranged at the bottom of the vehicle door 1, the sealing element cooperates with the sealing surface on the floor of the vehicle body to realize the sealing between the bottom of the vehicle door 1 and the vehicle body.

[0037] In this embodiment, the seal at the bottom of the door is a continuous seal with a constant longitudinal section, installed along the length direction of the bottom of the door 1 .

[0038] The structure of the seal includes: a seal cage 2, the seal cage 2 is a hollow structure, which increases the structural stability of the seal cage while ensuring light weight; the overall shape of the seal cage longitudinal section is hyperbolic, along the The bottom surface of the door is set to ensure the maximum contact area between the seal retainer and the door and the floor sealing su...

Embodiment 2

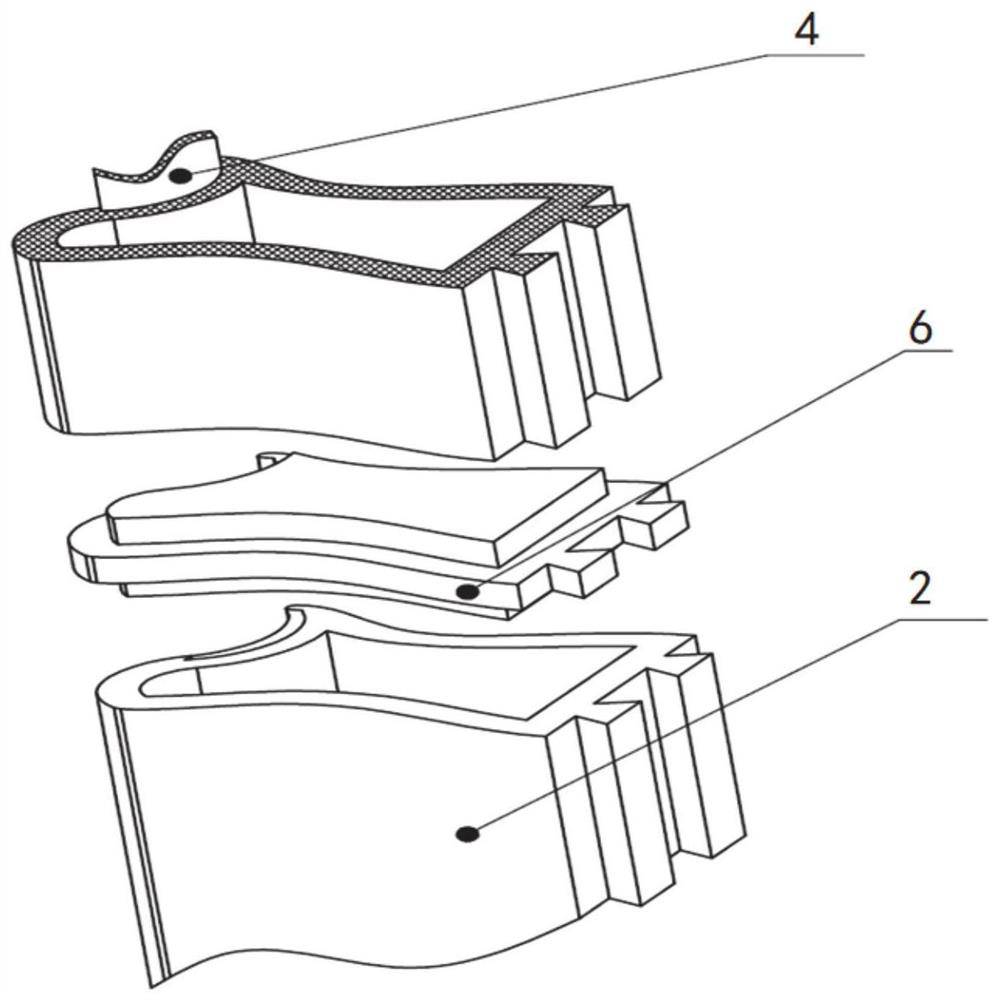

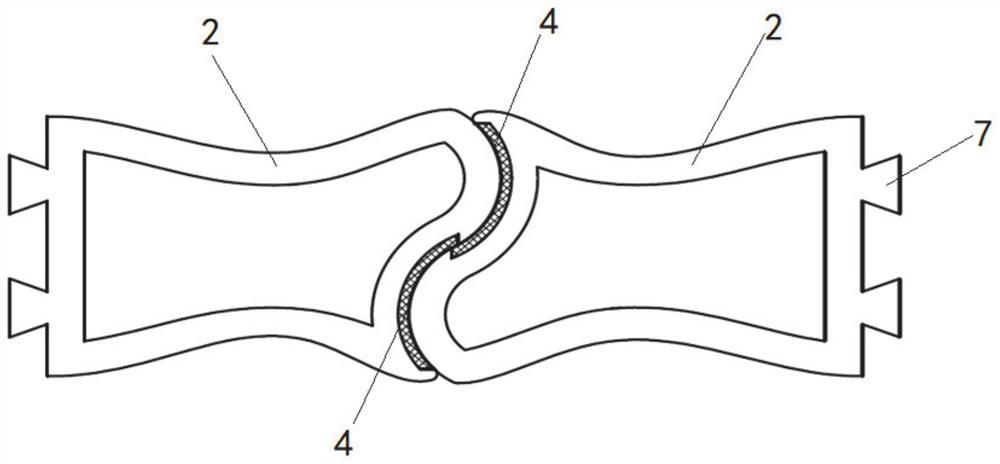

[0049] According to an embodiment of the present invention, an embodiment of a vehicle door sealing structure is provided, referring to figure 2 , including at least one section of seals respectively arranged on the opposite sides of the vehicle doors 1 on both sides;

[0050] The seal includes: a seal cage 2, the seal cage 2 is a hollow structure, which increases the structural stability of the seal cage while ensuring light weight; the overall shape of the seal cage longitudinal section is hyperbolic, along the side of the door setting, while satisfying the structural stability, it can ensure the maximum contact area between the seal retainer and the side of the door and the seal retainer, thereby enhancing the sealing effect; it should be noted that the longitudinal section here refers to the A longitudinal section in the width direction.

[0051] In this embodiment, the first side of the sealing cage 2 is an S-shaped arc surface in the length direction, and a soft sealin...

Embodiment 3

[0070] According to an embodiment of the present invention, an embodiment of a vehicle door sealing structure is provided, referring to Figure 5 , the door 1 is installed on both sides of the passenger compartment of the rail vehicle, and the door 1 is consistent with the arc of the body of the rail vehicle to keep the shape of the vehicle smooth, thereby reducing the aerodynamic resistance when the vehicle is running. The door is a sandwich structure, the two surface layers are mainly formed by sheet metal stamping, and the middle core layer is made of sound-proof cotton and supplemented by a connecting frame structure to ensure the overall connection strength and bearing capacity of the door. Sealing parts and the contact area 10 of the car body sealing part are arranged around the car door to ensure the sealing and sound insulation performance of the vehicle after the car door 1 is closed.

[0071] The door bottom seal 8 described in Embodiment 1 is arranged on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com