Raw material storage tank for food safety production

A food safety and storage tank technology, applied in the field of raw material storage tanks for food safety production, can solve the problems affecting the use quality of liquid raw materials, reducing the storage space of raw material storage tanks, etc., so as to slow down the swing speed and frequency, avoid cavity bubbles, The effect of pure raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

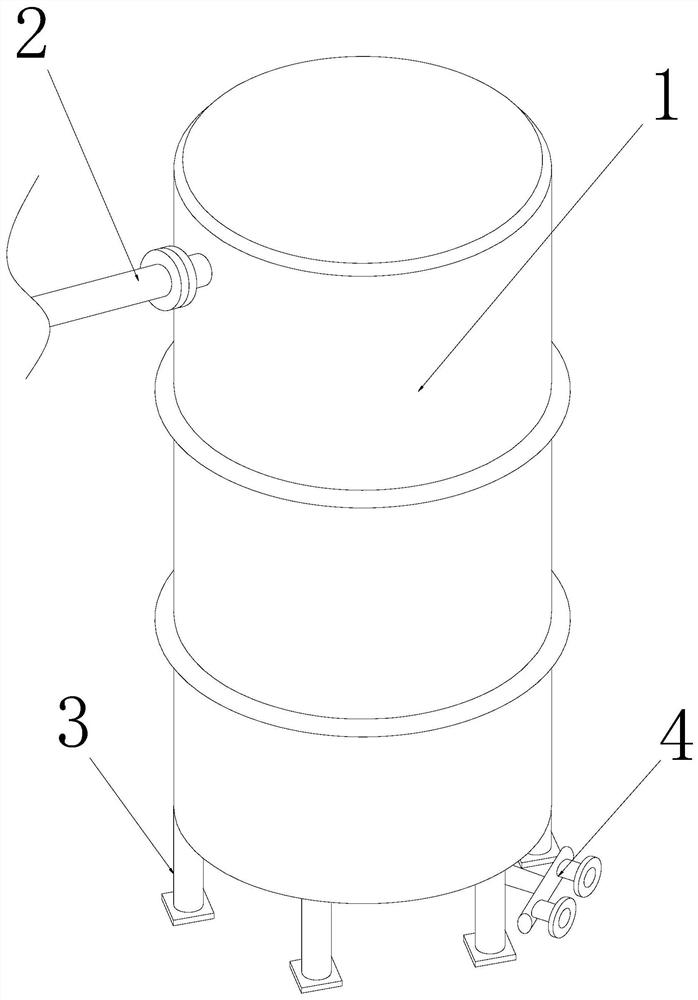

[0029] The invention provides a raw material storage tank for food safety production, the structure of which includes a tank body 1, a feed pipe 2, a column foot 3, and a discharge pipe 4, the tank body 1 is flange-connected with the feed pipe 2, and the The column foot 3 is welded and connected to the bottom of the tank body 1, and the discharge pipe 4 is flange-connected to the lower end of the tank body 1.

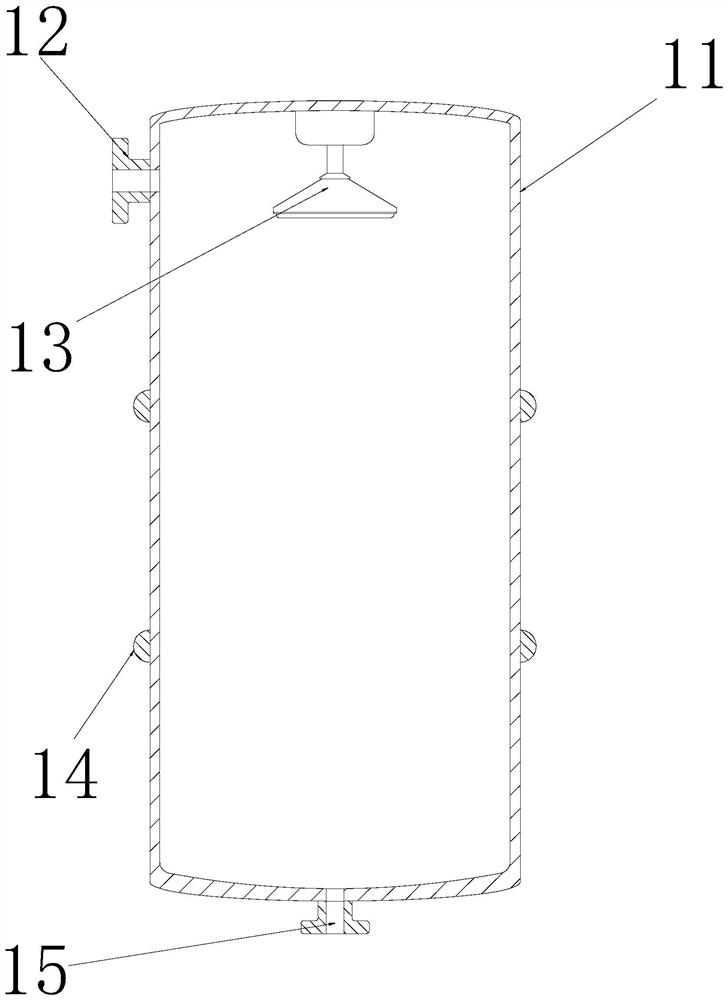

[0030] The tank body 1 is composed of a casing 11, a feed inlet 12, a material stopper 13, a hoop 14, and a discharge port 15. The feed inlet 12 is welded to the upper left side of the casing 11, and the material stopper 13 The upper end is welded and connected to the top of the inner wall of the shell 11 . There are two hoops 14 in total, and the two hoops 14 are respectively embedded and connected to the surface of the shell 11 .

[0031] The ma...

Embodiment 2

[0036] Example 2: Please refer to Figure 6-Figure 9 , the specific embodiments of the present invention are as follows:

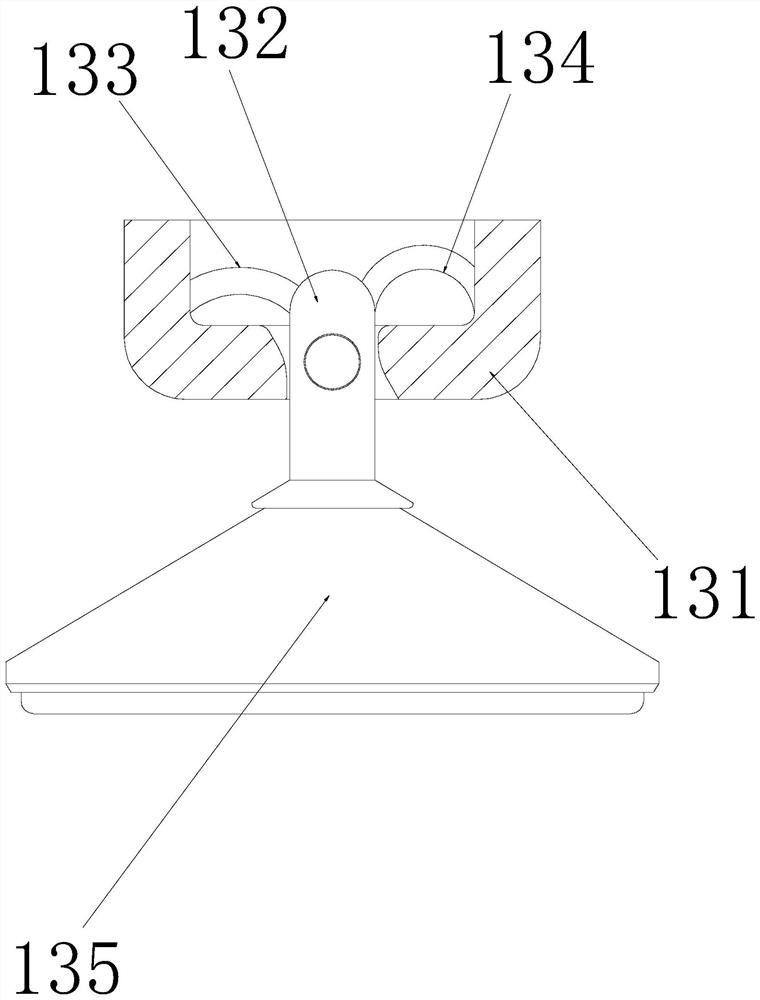

[0037] The present invention provides a raw material storage tank for food safety production. The material blocking device 135 is composed of a bracket 351, a stopper 352, and a material throwing tray 353. The stopper 352 is an umbrella-shaped structure with a narrow top and a wide bottom. The block 352 is welded to the upper end of the support 351, and the material throwing tray 353 is movably engaged on the surface of the support 351. When the material impulse reaches the surface of the throwing tray 353, the stopper 352 with an upper narrow and a lower wide umbrella structure can prevent the material from The splash flows into the gap between the throwing tray 353 and the support 351, preventing the material from being polluted.

[0038] The material rejection disc 353 is composed of a disc body 531, a slip ring 532, a rejection bar 533, and a blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com