Grid structure for silo roof

A network frame structure and network frame technology, which is applied in the direction of building construction and construction, can solve the problems of small rigidity of the warehouse roof, inability to bear force together, and deformation of the roof of the warehouse, so as to save purlins, reduce self-weight, and reduce the amount of steel used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

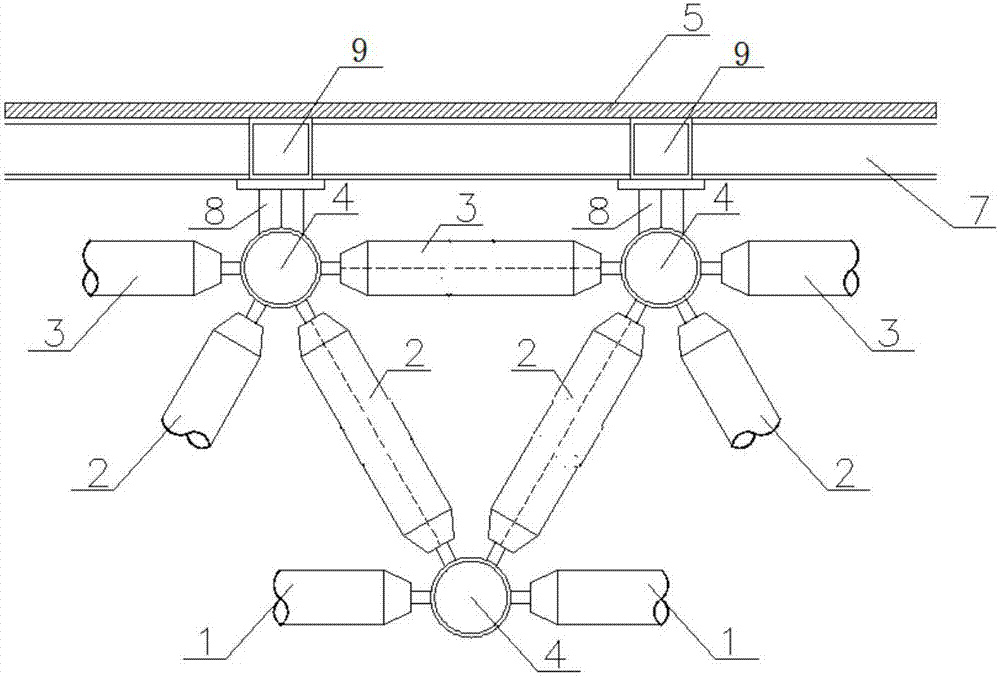

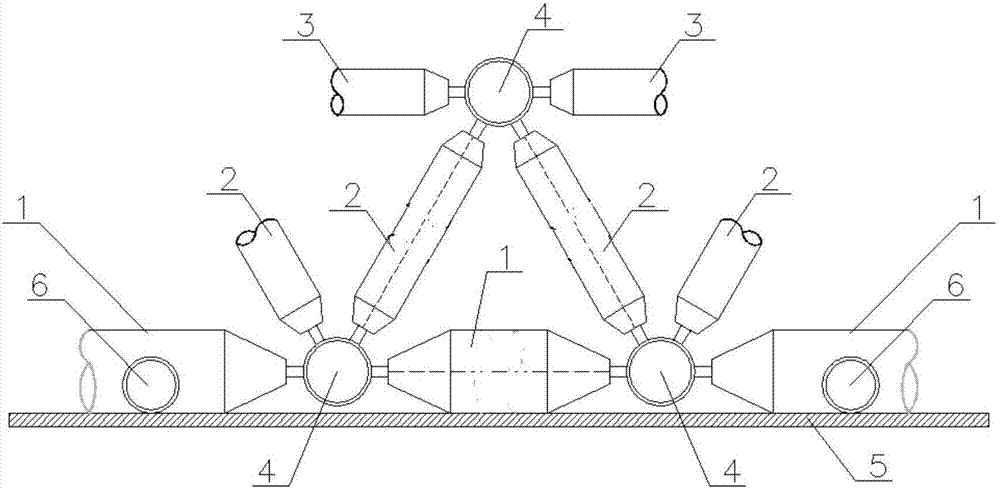

[0038] In order to improve the spatial rigidity and overall stability of the silo roof structure, a combined space structure system is formed by the grid structure and the roof plate to provide a grid structure for the silo roof, such as figure 2 As shown, it mainly includes grid rods (including grid lower chord 1, grid web 2 and grid upper chord 3), grid ball joints 4, warehouse roof 5 and warehouse roof stiffener 6. The network frame structure is arranged above the warehouse roof 5, and the lower chord member 1 of the network frame and the warehouse roof 3 are connected by welding.

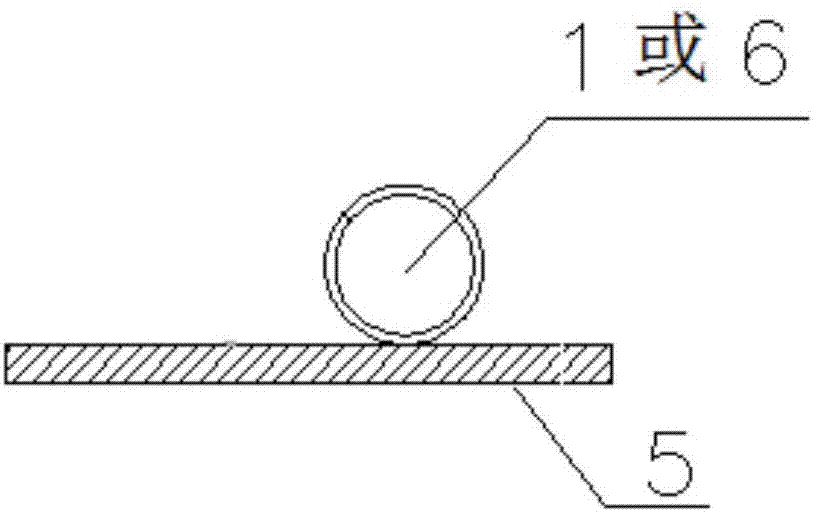

[0039] The cross-sectional shape of the grid lower chord 1 is circular, and its diameter will be greater than the diameter of the grid ball node 4 so as to be directly welded with the warehouse roof 5. Due to the direct increase, the wall thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com