Outer wall plate waterproof node

An external wall panel and node technology, applied in the direction of walls, building components, building insulation materials, etc., can solve problems such as affecting the appearance, unsuitable for external wall thermal insulation panels, and unfavorable for the transportation of internal partitions in external walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

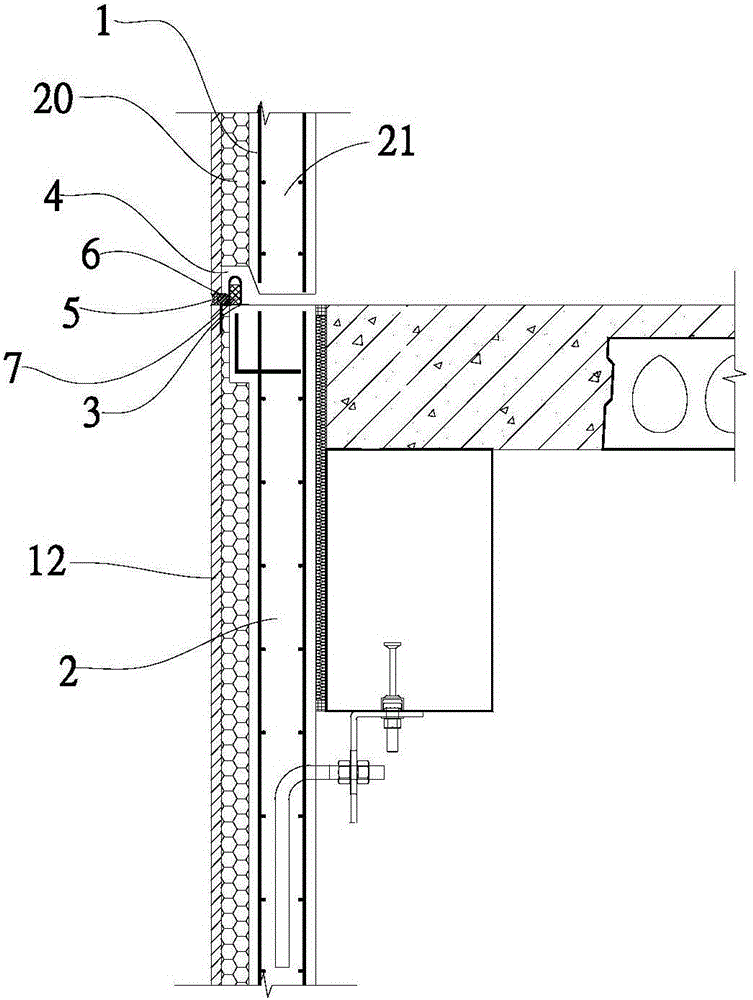

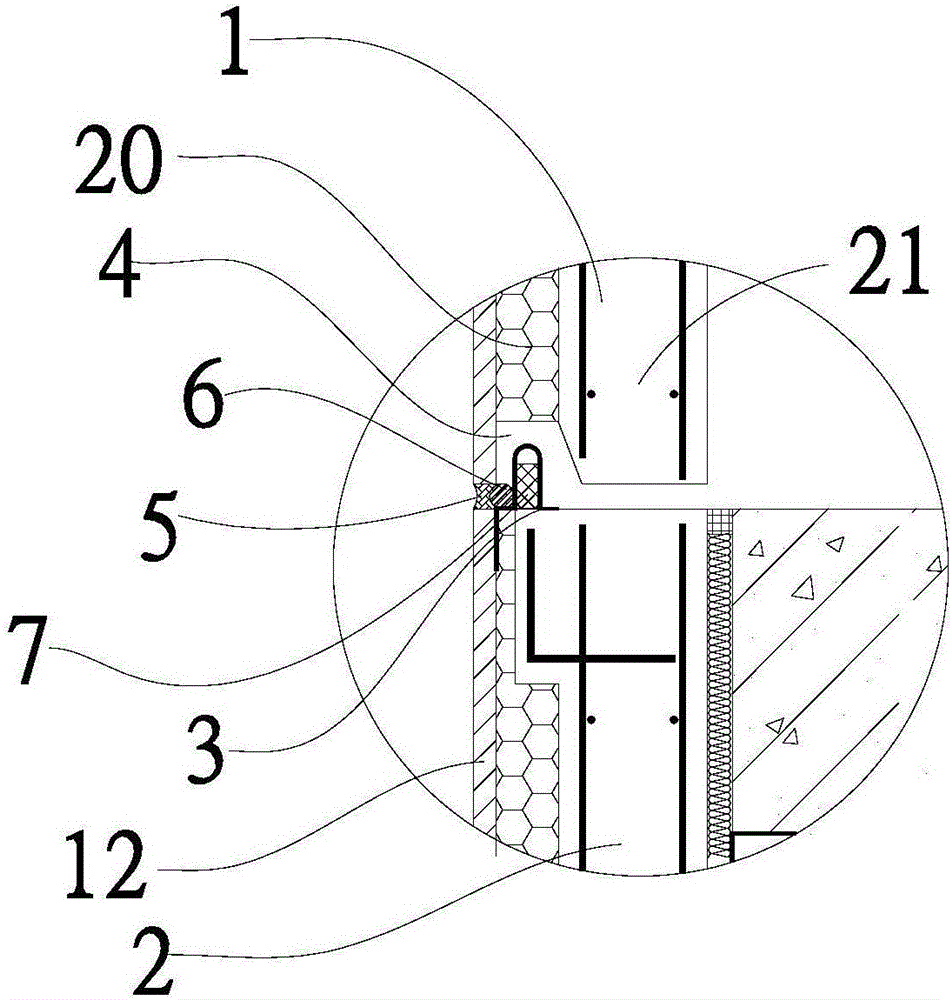

[0032] Embodiments of the present invention are as follows, with reference to figure 1 with figure 2 , a waterproof node of an exterior wall panel, comprising an upper exterior wall panel 1 and a lower exterior wall panel 2, the upper exterior wall panel 1 and the lower exterior wall panel 2 at least including an outer leaf plate 12, an insulation layer 20 and a structural layer 21 , the thermal insulation layer 20 is arranged between the outer leaf board 12 and the structural layer 21, the upper outer wall panel 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com