Evaluation method for physical and chemical action of drilling fluid and shale formation

An evaluation method, mud shale technology, applied in mining geology, oil and gas drilling borehole stability, and oil and gas drilling fields, can solve the problems of lack of comparability, inability to reflect the impact speed and strength of drilling fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

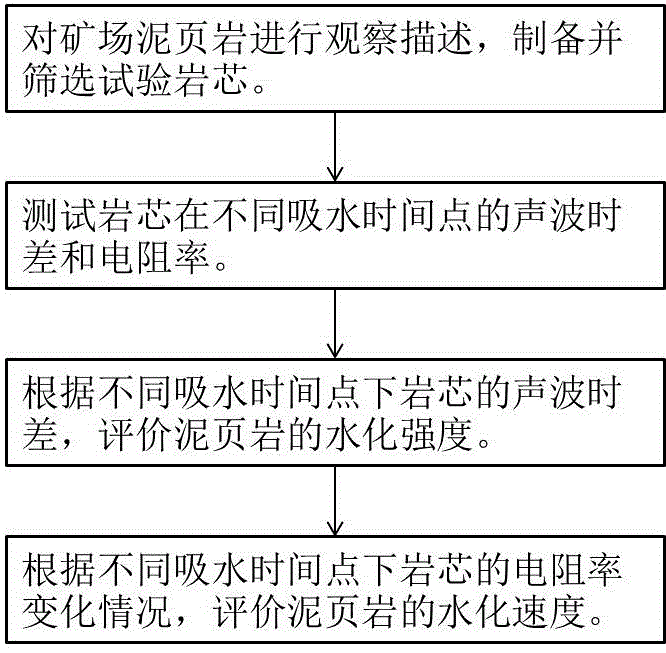

[0026] Such as figure 1 As shown, an evaluation method for the physical and chemical interaction between drilling fluid and shale formation, which includes the following steps in sequence:

[0027] The first step is to observe and describe the mud shale in the mine, prepare and screen core samples;

[0028] The second step is to test the acoustic time difference and resistivity of the core at different water absorption time points under the formation conditions;

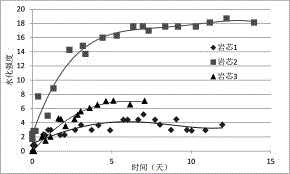

[0029] The third step is to evaluate the hydration intensity of the shale according to the acoustic time difference of the core at different water absorption time points;

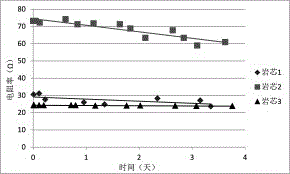

[0030] The fourth step is to evaluate the hydration rate of the mud shale according to the change of the resistivity of the core at different water absorption time points;

[0031] In the first step, observe the shale and determine the direction of its bedding plane, use an air corer to drill cores along the normal direction perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com