A high elongation composite anchor cable and its installation method

A technology with high elongation and installation method, which is applied in the installation of anchor rods, earth cube drilling, mining equipment, etc., can solve the problems of anchorage failure, cable body breakage, instability, etc., achieve high strength and elongation, and facilitate separation and installation , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

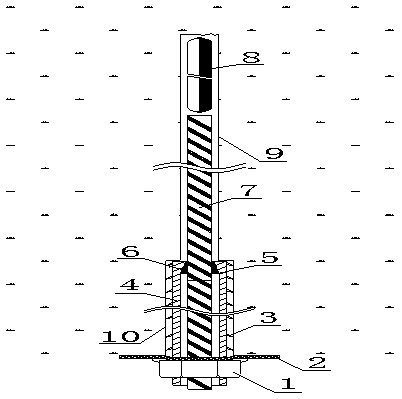

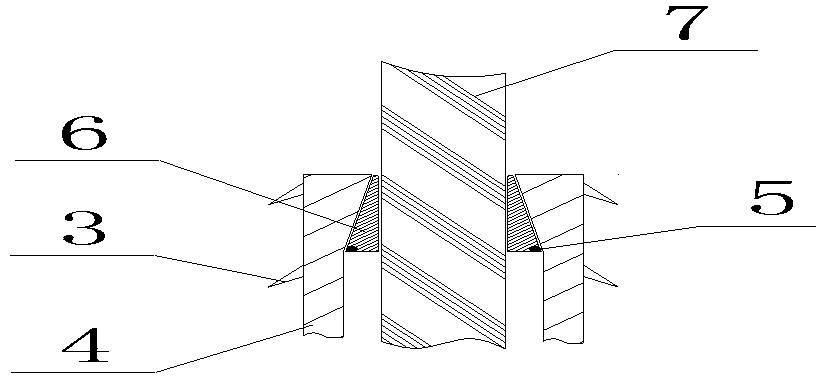

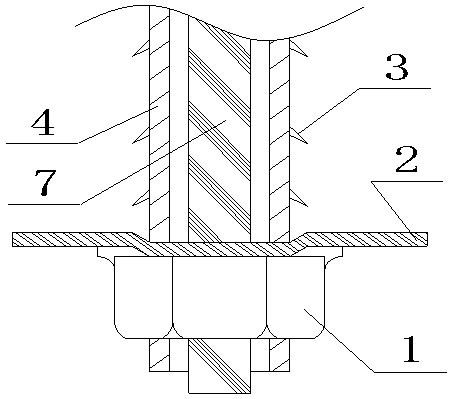

[0015] refer to figure 1 , figure 2 , image 3 To illustrate the present invention, a high-elongation composite anchor cable includes a cable body 7, a high-elongation sleeve 4, a lock 1 (take nut fastening as an example), a tray 2, an embedded card 6, and a ring spring 5. The top end of the cable body 7 is anchored in the deep part of the borehole 9, and the high elongation sleeve 4 is placed on the end of the cable body 7. The cable body 7 and the high elongation sleeve 4 form a tight connection structure through the embedded card 6, and the ring spring 5 ensures During installation, the embedded cards 6 are regularly arranged on the cable body 7, and the lock 1 is fastened to the end of the high-elongation sleeve 4, and the tray 2 is closely attached to the surrounding rock of the roadway. The ultimate breaking force of the high elongation sleeve 4 should be greater than or equal to 80% of the ultimate breaking force of the cable body 7, and the cable body can be adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com