Fluid-controlled ultra-high pressure two-way stop valve and method for fluid cut-off or communication

A fluid communication and ultra-high pressure technology, applied in the hydraulic field, can solve problems such as high requirements for hydraulic control check valves, failure of hydraulic control check valves, failure of ultra-high pressure, etc., to achieve reliable cut-off effect, high cut-off reliability, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

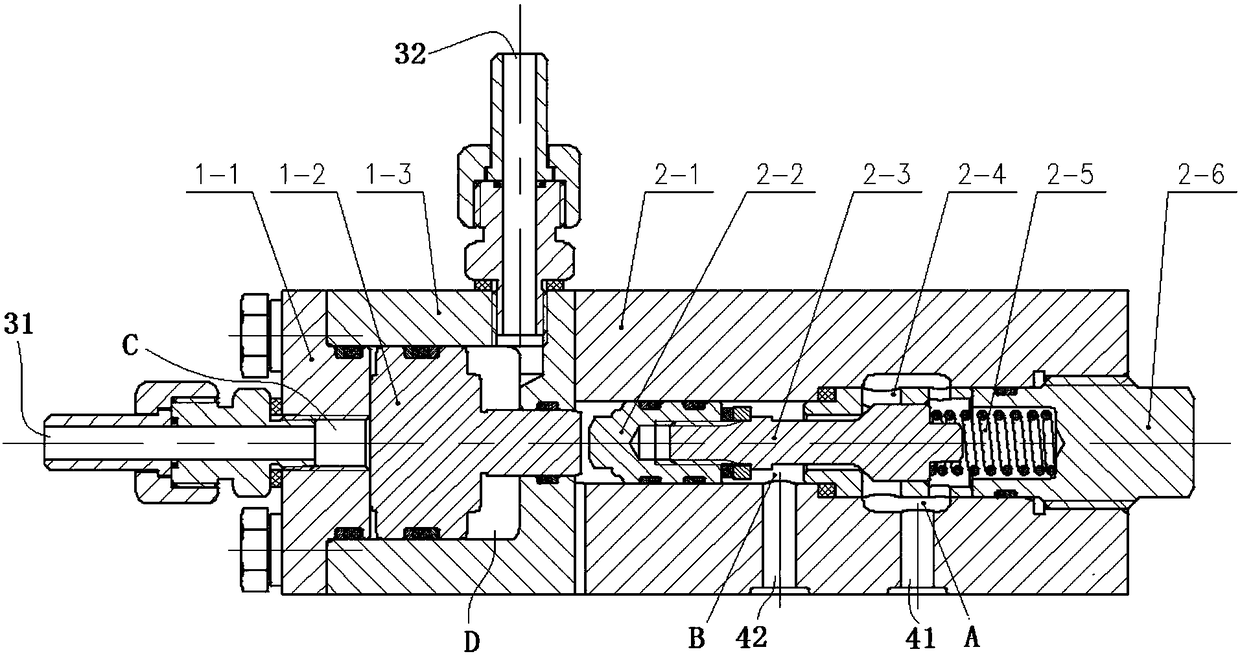

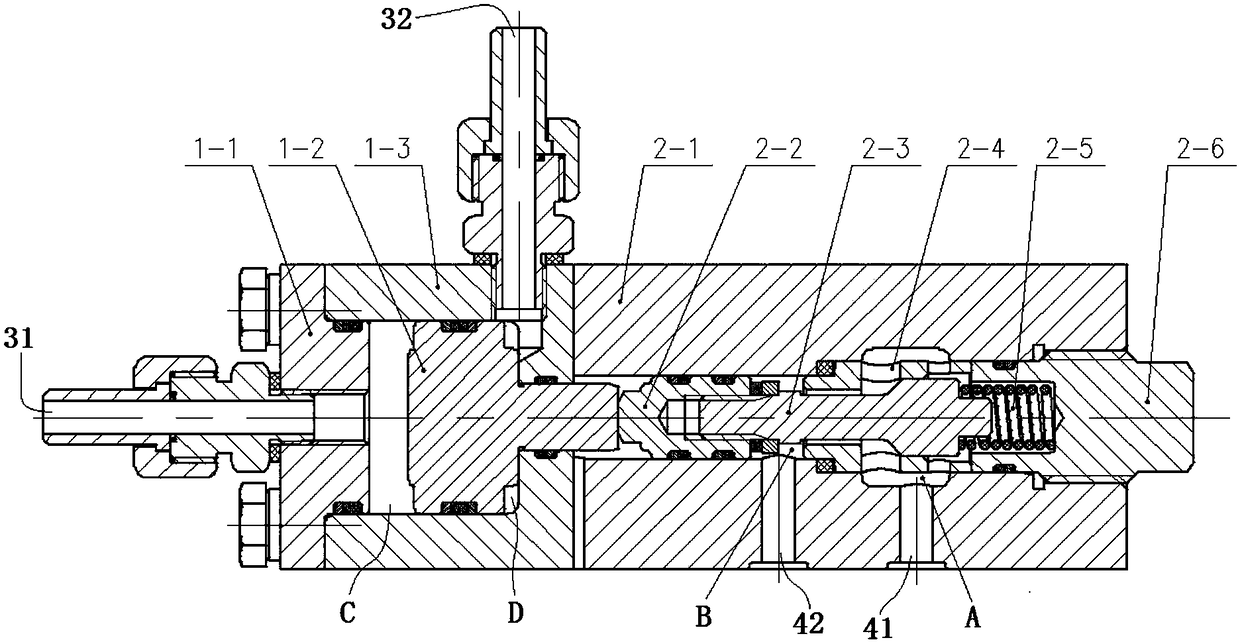

[0036] A hydraulically controlled ultra-high pressure two-way stop valve for fluids, such as figure 1 and figure 2 As shown, it includes two major parts, the oil control valve group and the liquid control valve group. The oil control valve group includes the oil chamber end cover 1-1, the oil chamber piston 1-2, and the oil control valve body 1-3; Valve body 2-1, intermediate piston 2-2, conical piston 2-3, valve sleeve 2-4, compression spring 2-5, plug 2-6.

[0037]The intermediate piston 2-2 is sealed with the liquid control valve body 2-1 through more than two O-rings plus back-up rings in a piston sealing form. The conical surface piston 2-3 is inserted into the valve sleeve 2-4, and the conical surface is ground to coincide with the inner step of the valve sleeve, so that the conical surface can be sealed. The conical front end of the conical piston 2-3 is connected with a thin rod and passes through the central circular hole of the valve sleeve 2-4. The diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com