A kind of igniter for discharging jet

An igniter and jet-releasing technology, which is applied in the directions of combustion ignition, ignition through the guide flare, combustion method, etc., can solve the problems of low ignition reliability, poor safety, inconvenient installation, etc., and achieve safe and reliable ignition, safe and reliable ignition, Strong flame effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

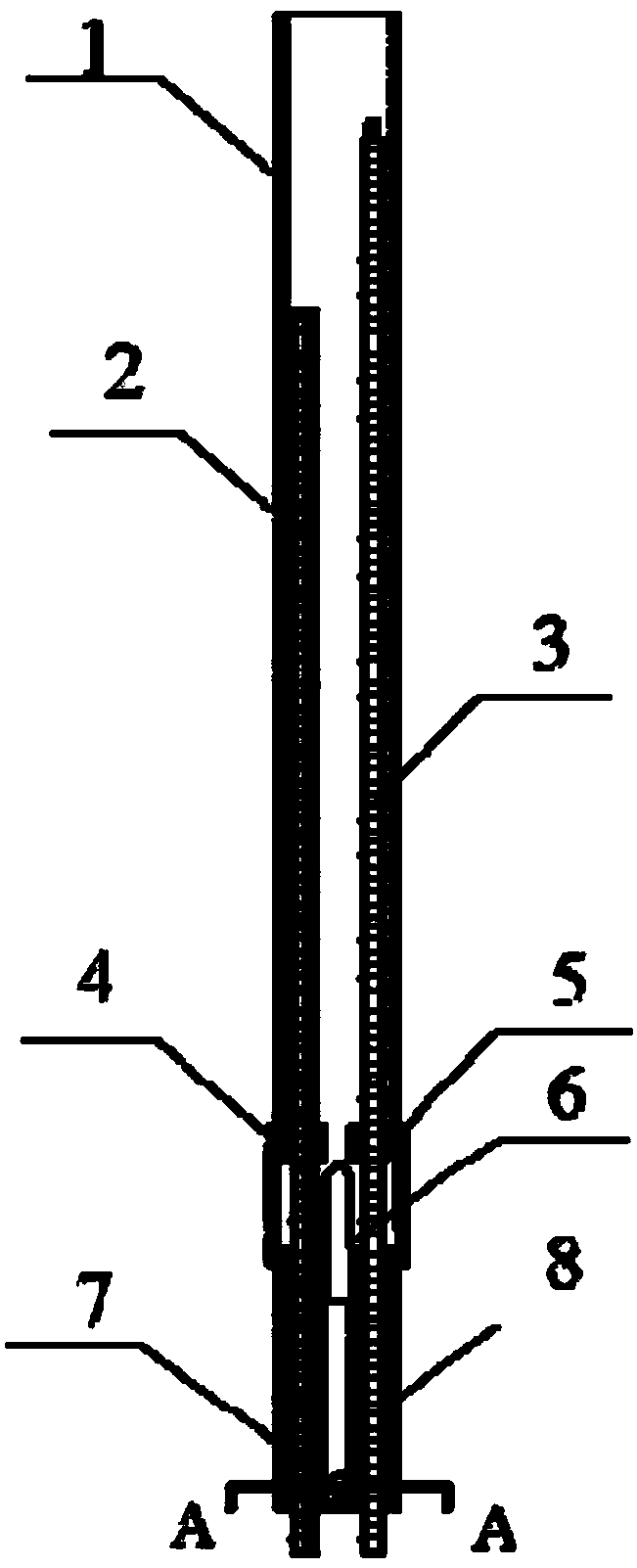

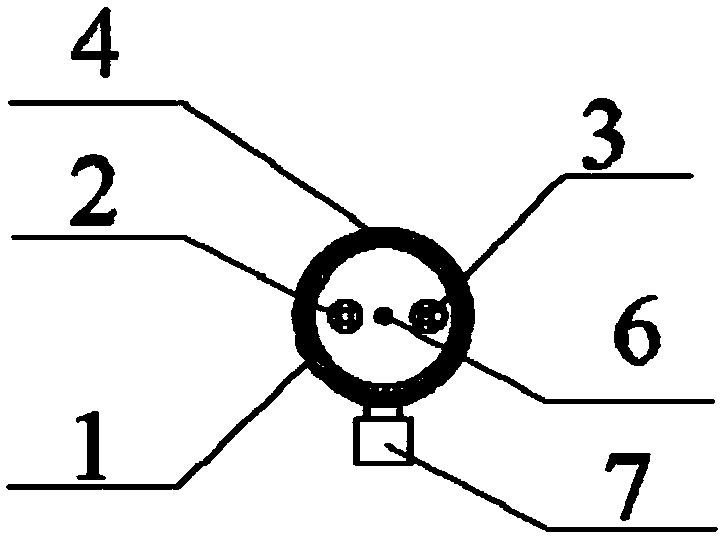

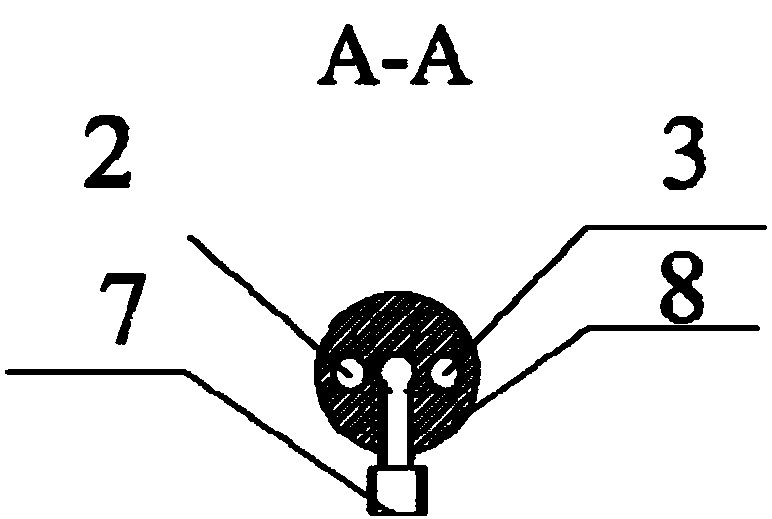

[0019] An igniter for blowing gas, such as Figure 1 to Figure 3 As shown, a combustion tube 1 is included, an ignition needle 2 and a flame probe 3 are arranged in the combustion tube 1, the combustion tube 1 is connected with a burner joint 8, and a nozzle 6 is provided on the burner joint 8. The bottom of the combustion tube 1 is provided with a fuel gas inlet 7 .

[0020] In the above embodiments, the combustion cylinder 1 is provided with a limiting hole 5 .

[0021] In the above embodiments, the combustion cylinder 1 is connected to the burner joint 8 through the connecting rod 4 .

[0022] In the above embodiments, the fuel gas inlet 7 is connected to the intake pipeline of liquefied petroleum gas or atomized diesel gas.

[0023] In the above embodiments, the fuel gas inlet 7 is connected to the liquefied petroleum gas or atomized diesel gas inlet pipe through threads or flanges.

[0024] In the above embodiments, the burner joint 8 is provided with a fuel flow chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com