System and method for modifying harmonic oscillator based on chemical etching integrated quartz cylindrical shell

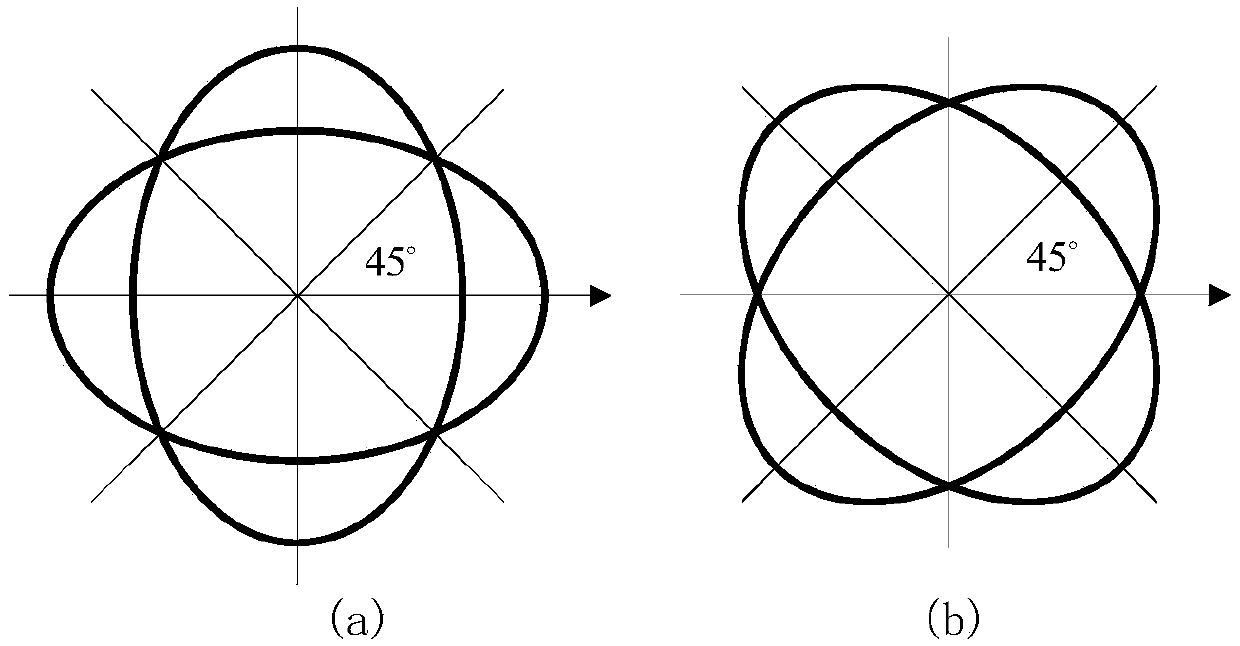

A cylindrical shell and chemical etching technology, which is applied to instruments and gyro effects for speed measurement, surveying and navigation, etc., can solve the problem of difficulty in guaranteeing the symmetry of the machining of the modified groove, affecting the quality factor of the harmonic oscillator, and reducing the quality factor of the harmonic oscillator and other problems, to achieve the effect of low cost, correct mode shape offset angle, and reduce frequency cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

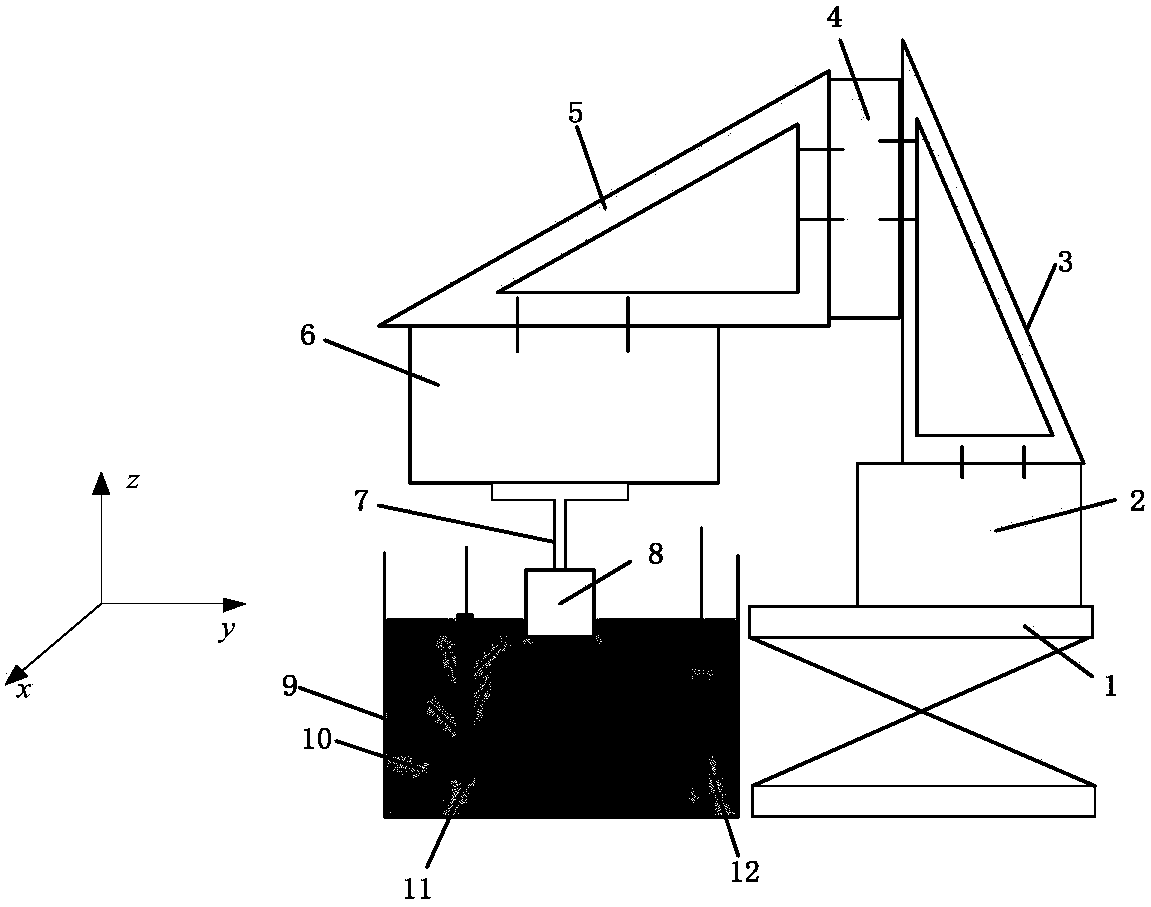

[0049] The specific embodiments of the present invention will be further described below in conjunction with Ansys software simulation.

[0050] The present invention carries out the chemical modification method for the integrated quartz cylindrical shell resonator, the method comprises the steps:

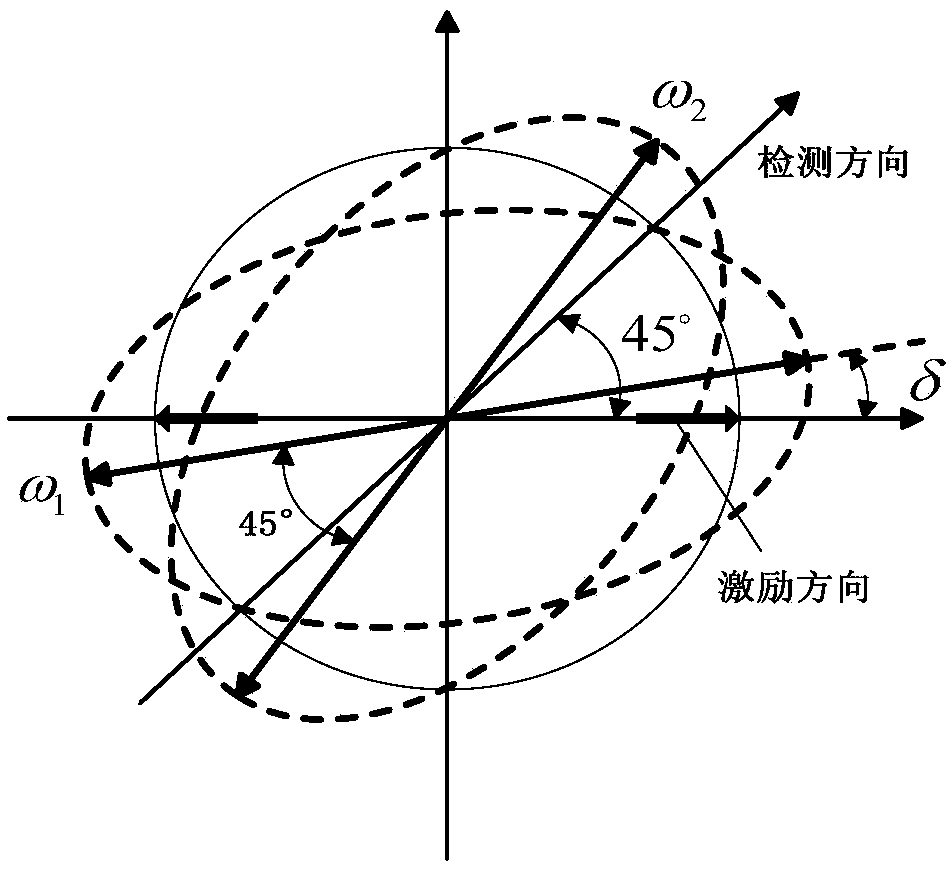

[0051] S1, determine the vibration main axis direction of the resonator: firstly determine the excitation mode and sensitive mode frequency of the resonator by sweeping the frequency of the resonator, and then apply a sinusoidal signal with the resonant frequency as the period to the resonator to make the resonator vibrate freely. The direction of the mode shape when the vibration is stable is the direction of the main axis of the vibration of the resonator;

[0052] S2, correct the deviation angle of the mode shape and measure the frequency cracking: use a cotton swab dipped in chemical correction fluid to apply it to one side of the main shaft of the resonator to remove the mass,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com