A lens adapter ring

A transfer and lens technology, applied in the field of photographic equipment, can solve problems such as top deformation, top breaking, lens top flower, etc., and achieve the effect of balanced force, convenient screwing operation, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

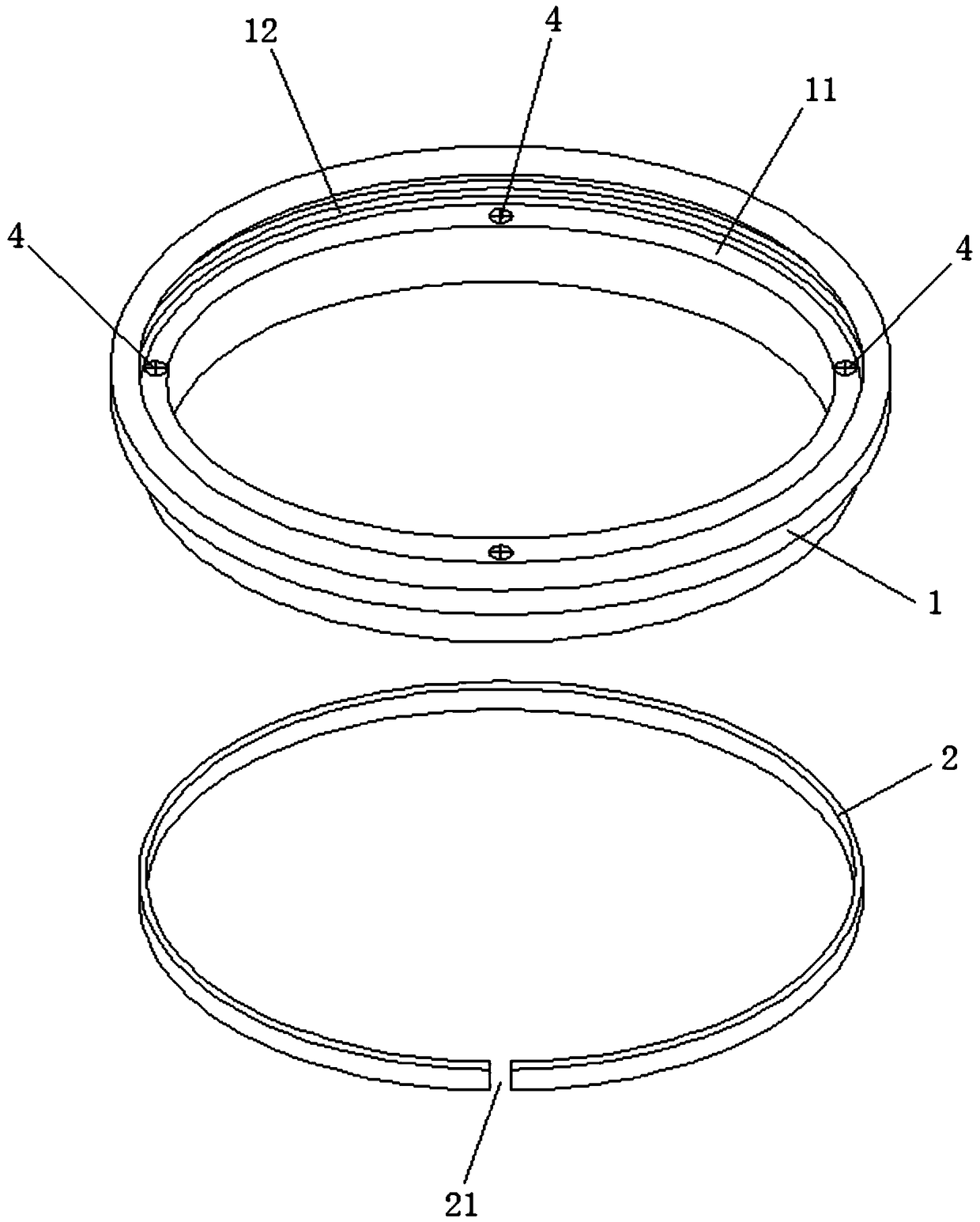

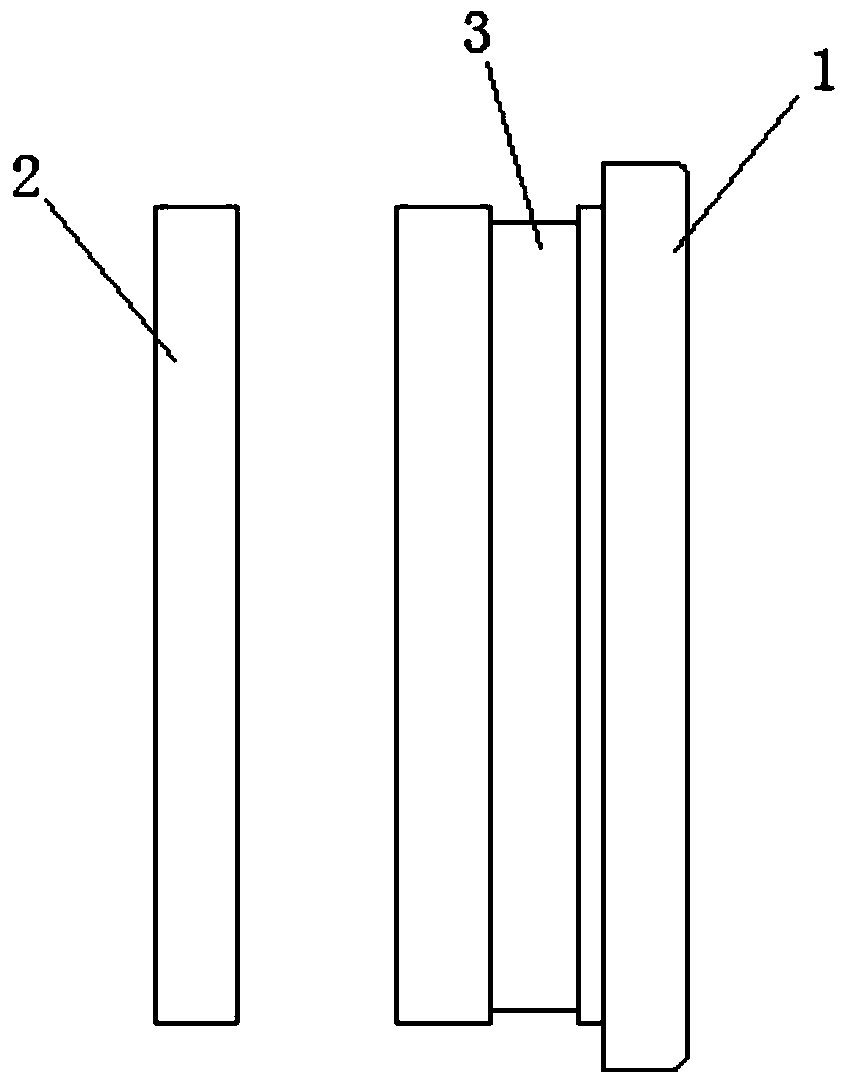

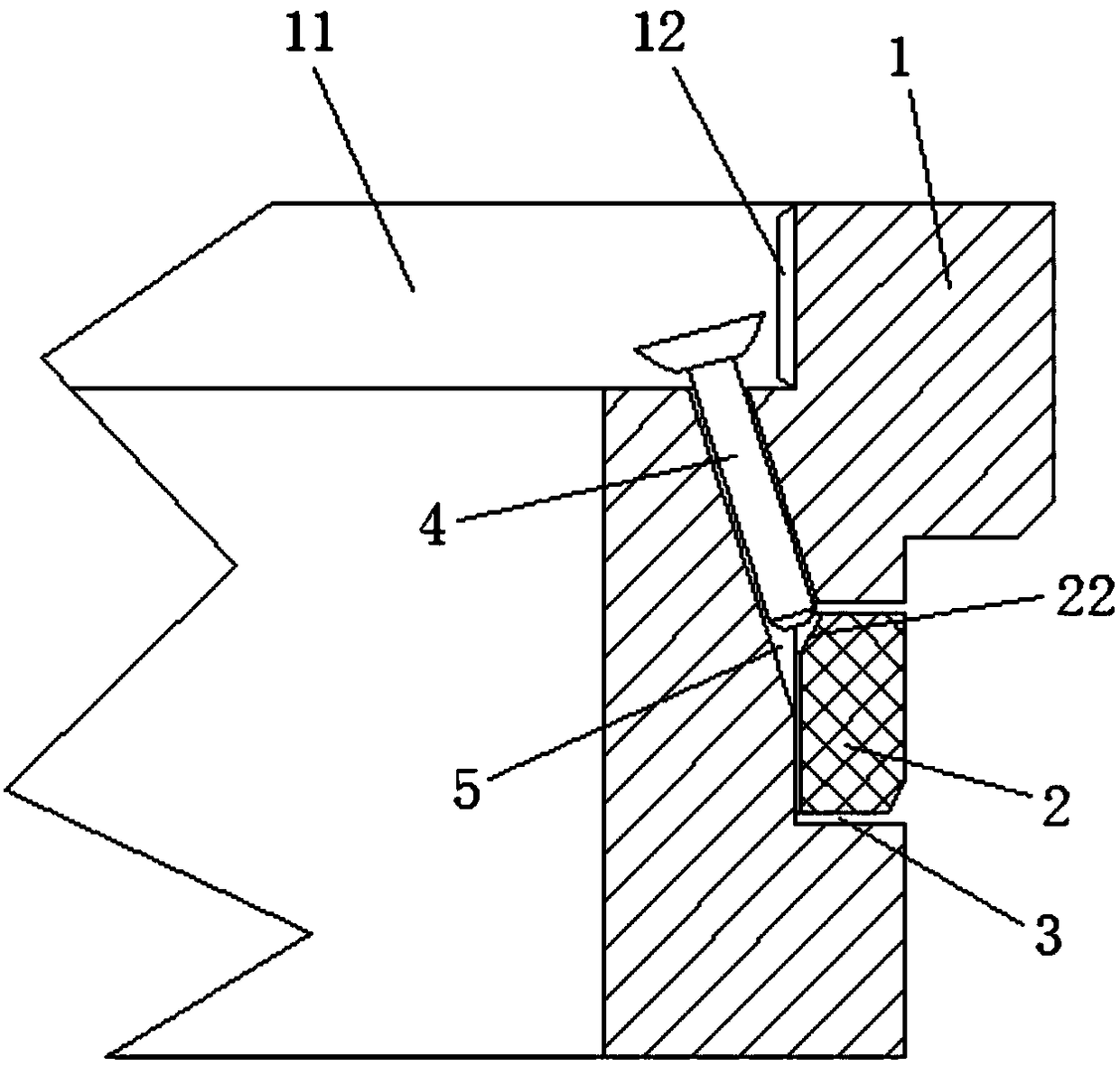

[0027] Such as Figure 1 to Figure 5 As shown in , Embodiments 1 and 2 of the present invention provide a lens adapter ring, including an adapter ring main body 1 and an external expansion fixing ring 2; wherein, the circumferential outer surface of the adapter ring main body 1 is provided with An annular groove 3, and the front end of the main body 1 of the adapter ring is provided with an external expansion drive mechanism; Under the action, it bulges outward and is higher than the peripheral outer surface of the main body 1 of the adapter ring. The specific structure can be as follows: the adapter ring main body 1 can be made of metal material or plastic material, and the external expansion fixing ring 2 can be a circular ring with a gap 21, and can be made of plastic material (of course , the expansion fixing ring 2 can also be a complete ring without a gap, and can also be made of silica gel material or elastic metal material.). The external expansion driving mechanism ...

Embodiment 3

[0032] Such as Figure 6 As shown in , Embodiment 3 of the present invention provides a lens adapter ring, the structure of which is basically the same as Embodiment 1 and Embodiment 2, including an adapter ring main body 1 and an external expansion fixing ring 2; wherein, the adapter ring The circumferential outer surface of the main body 1 is provided with an annular groove 3, and the front end of the adapter ring main body 1 is provided with an external expansion drive mechanism, and the external expansion drive mechanism includes more than two external expansion screws 4 and arranged in a ring array. There are more than two screw holes 5 at the front end of the main body 1 of the adapter ring. The expansion fixing ring 2 is arranged in the annular groove 3, and is connected with the drive mechanism of the expansion, and outwardly under the action of the drive mechanism of the expansion. Swell and be higher than the circumferential outer surface of the main body 1 of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com