Elastic conducting film material and preparation method thereof

A technology of elastic conductive and membrane material, applied in cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc. Stable performance, not easy to wear and leak, improve electrical safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

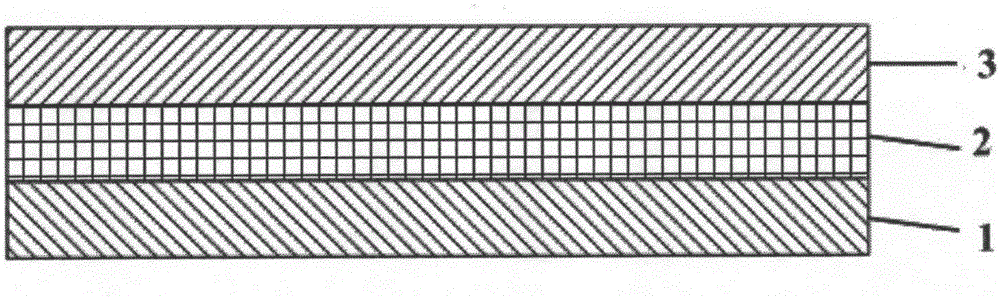

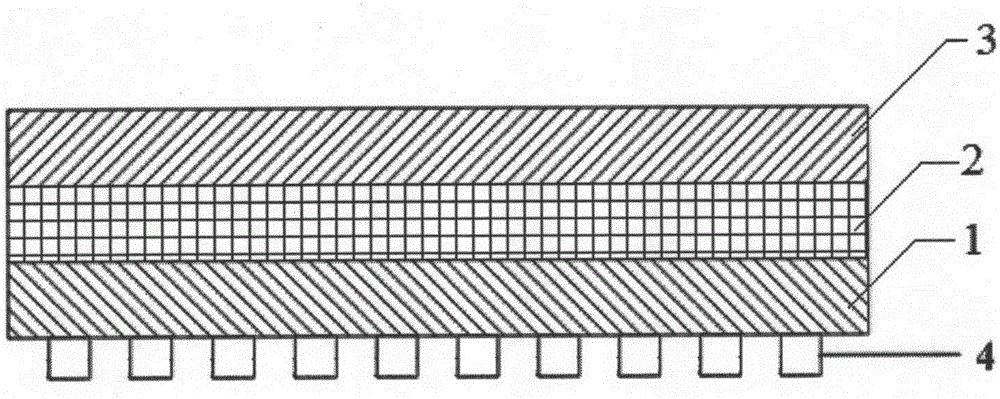

[0035] A preparation method of an ultra-thin elastic conductive film material, the specific steps are:

[0036] The first step: select the elastic film 1 (PDMS film) as the elastic attachment matrix, apply a certain tension to both ends of it, stretch it to 40% of the elongation at break of the elastic film and fix it, and coat the surface of the PDMS film with a A layer of liquid elastic adhesive (using PDMS adhesive) to form an adhesive layer with a thickness of about 0.2mm;

[0037] The PDMS membrane is a square PDMS membrane with a size of 30×30cm 2 , the thickness is 0.5mm. The PDMS film was obtained by coating film method using PDMS resin (Dow Corning DC184).

[0038] The PDMS adhesive adopts SYLGARD184 of Dow Corning Company, which is obtained by mixing the basic components (PDMS liquid, viscosity 5.2 Pa-sec) and curing agent (viscosity 3.5 Pa-sec) in a weight ratio of 10:1.

[0039] The second step: using silver glue to bond the copper wire electrode and the carbon ...

Embodiment 2

[0046] A preparation method of an elastic conductive film, the specific steps are:

[0047] The first step: select the elastic film 1 (PDMS film) as the elastic attachment matrix, apply a certain tension to both ends of it, stretch it to 50% of the elongation at break of the elastic film and fix it, and coat the surface of the PDMS film with a A layer of liquid elastic adhesive (using PDMS adhesive) to form an adhesive layer with a thickness of about 0.2mm;

[0048] The PDMS membrane is a square PDMS membrane with a size of 30×30cm 2 , the thickness is 0.5mm. The PDMS film was obtained by coating film method using PDMS resin (Dow Corning DC184).

[0049] The PDMS adhesive adopts SYLGARD184 of Dow Corning Company, which is obtained by mixing the basic components (PDMS liquid, viscosity 5.2 Pa-sec) and curing agent (viscosity 3.5 Pa-sec) in a weight ratio of 10:1.

[0050] The second step: using silver glue to bond the copper wire electrode and the carbon nanotube film to obt...

Embodiment 3

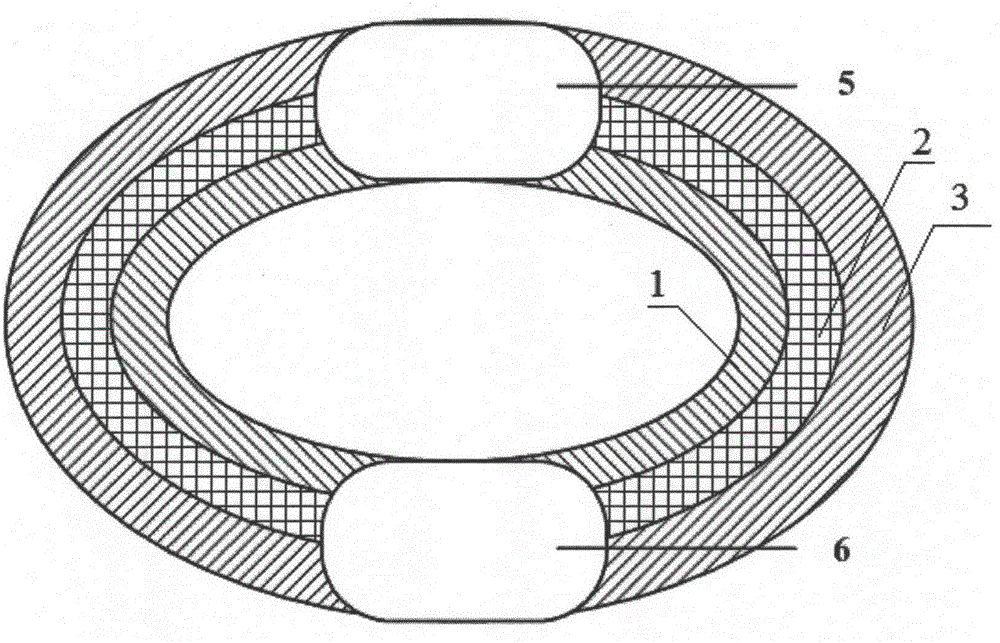

[0058] A preparation method of an elastic conductive bracelet, the specific steps are:

[0059] The first step: select the elastic film 1 (PDMS film) as the elastic attachment matrix, apply a certain tension to both ends of it, stretch it to 50% of the elongation at break of the elastic film and fix it, and coat the surface of the PDMS film with a A layer of liquid elastic adhesive (using PDMS adhesive) to form an adhesive layer with a thickness of about 0.2mm;

[0060] The PDMS membrane is a rectangular PDMS membrane with a size of 1.5*16cm 2 , the thickness is 0.4mm. The PDMS film was obtained by coating film method using PDMS resin (Dow Corning DC184).

[0061] The PDMS adhesive adopts SYLGARD184 of Dow Corning Company, which is obtained by mixing the basic components (PDMS liquid, viscosity 5.2 Pa-sec) and curing agent (viscosity 3.5 Pa-sec) in a weight ratio of 10:1.

[0062] The second step: using silver glue to bond the copper wire electrode and the carbon nanotube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com