Acoustic material for loudspeaker

A sound-absorbing material and speaker technology, applied in the field of sound-absorbing materials, can solve problems such as the inability to meet the needs of micro-speaker speaker acoustic performance debugging and correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

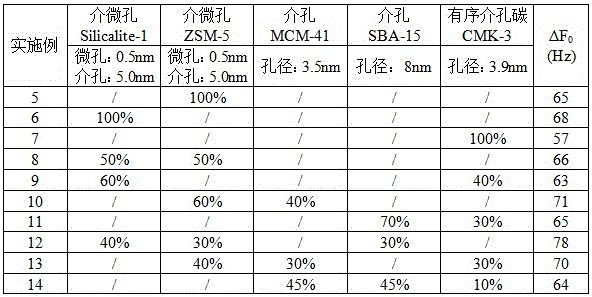

[0020] The sound-absorbing material is a microporous Y zeolite material with a pore size of 0.74nm. After the test, F 0 Reduced by 28Hz, count △F 0 =28Hz.

Embodiment 2

[0022] The sound-absorbing material is a microporous 13X zeolite material with a pore size of 1nm. After the test, F 0 Reduced by 25Hz, count △F 0 =25Hz.

Embodiment 3

[0024] The sound-absorbing material is a mixture of microporous Y zeolite with a mass ratio of 50% and microporous 13X zeolite with a mass ratio of 50%. After the test, F 0 Reduced by 26Hz, count △F 0 =26Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com