Striker bracket attachment structure for vehicular hood

A technology for engine hoods and engine rooms, applied in vehicle locks, vehicle parts, building structures, etc., can solve problems such as difficulty in ensuring head protection performance, difficult to ensure travel, etc., and achieve the effect of relieving the concentration of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

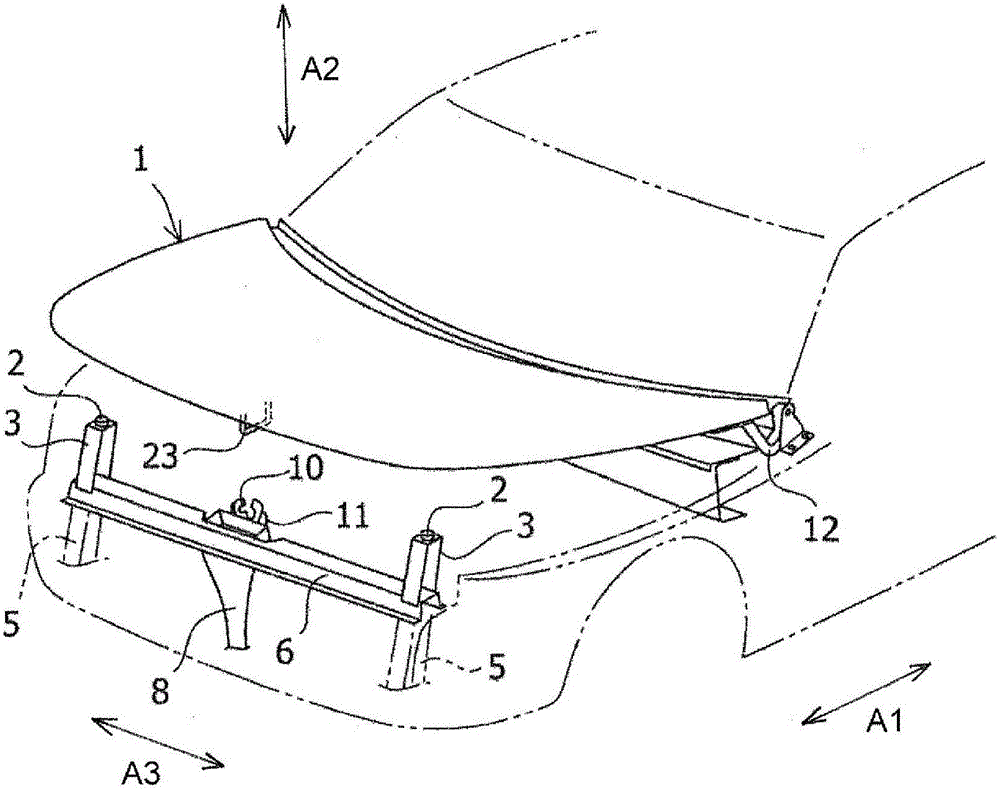

[0031] Below, use the attached drawings ( Figure 1 ~ Figure 5 ), an embodiment of the striker bracket attachment structure of the vehicle engine cover of the present invention will be described. figure 1 It is a brief representation of the vehicle front and rear direction of the vehicle having the striker bracket mounting structure of the vehicle hood of the present embodiment (in the figure 1 Is represented by arrow A1. ) Is a perspective view of the front part (front part of the vehicle). It should be noted that in figure 1 Here, the main body side of the vehicle body is imaginatively represented, and only the brief arrangement of the striker 23 is shown on the engine hood side, and the striker bracket 21 and the hood inner panel 20 are not shown.

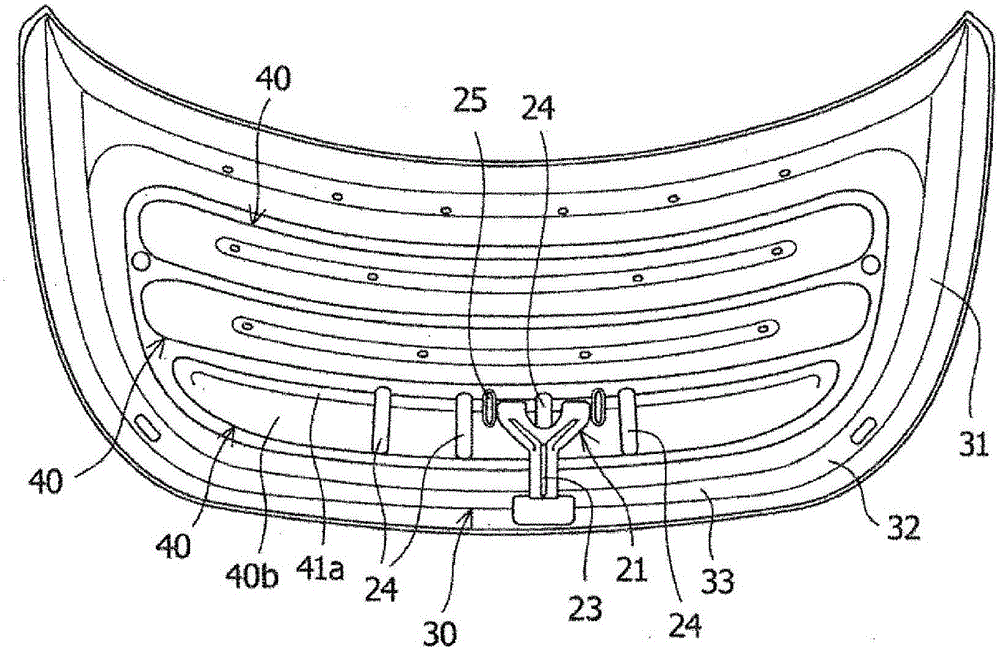

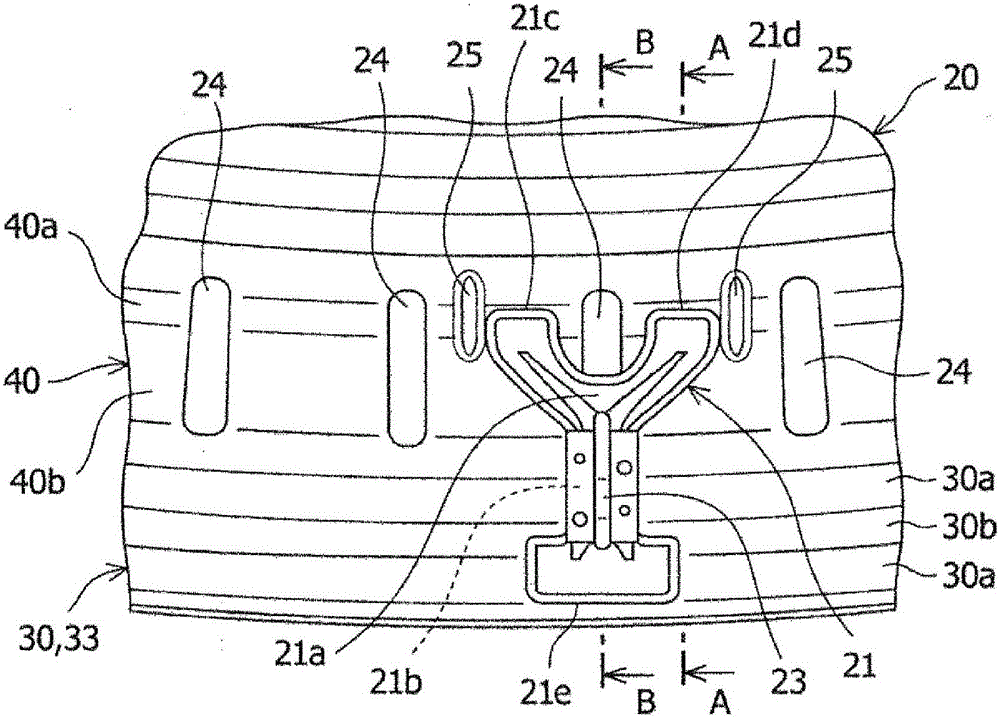

[0032] figure 2 Observed from under the vehicle figure 1 Bottom view of the inner side panel 20 of the hood. image 3 Is to figure 2 An enlarged bottom view showing the periphery of the striker bracket 21 enlarged. Figure 4 Yes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com