Grass baffle for grass cutter

A lawn baffle and lawn mower technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of single structure and function of lawn baffles, low mowing efficiency, and reduced contact area, etc. Mowing efficiency, avoid contact surface reduction, easy removal and installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

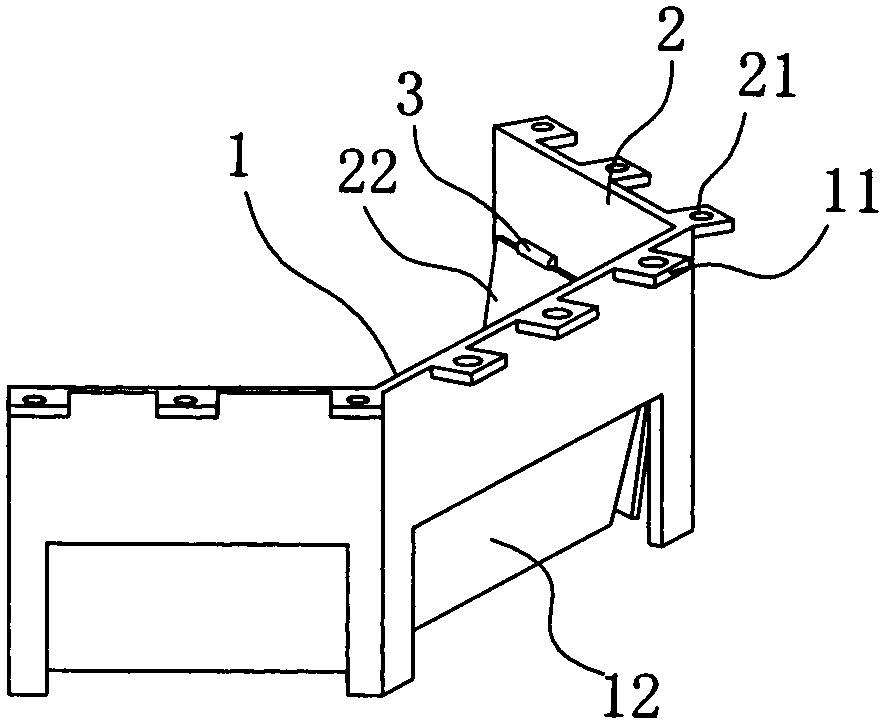

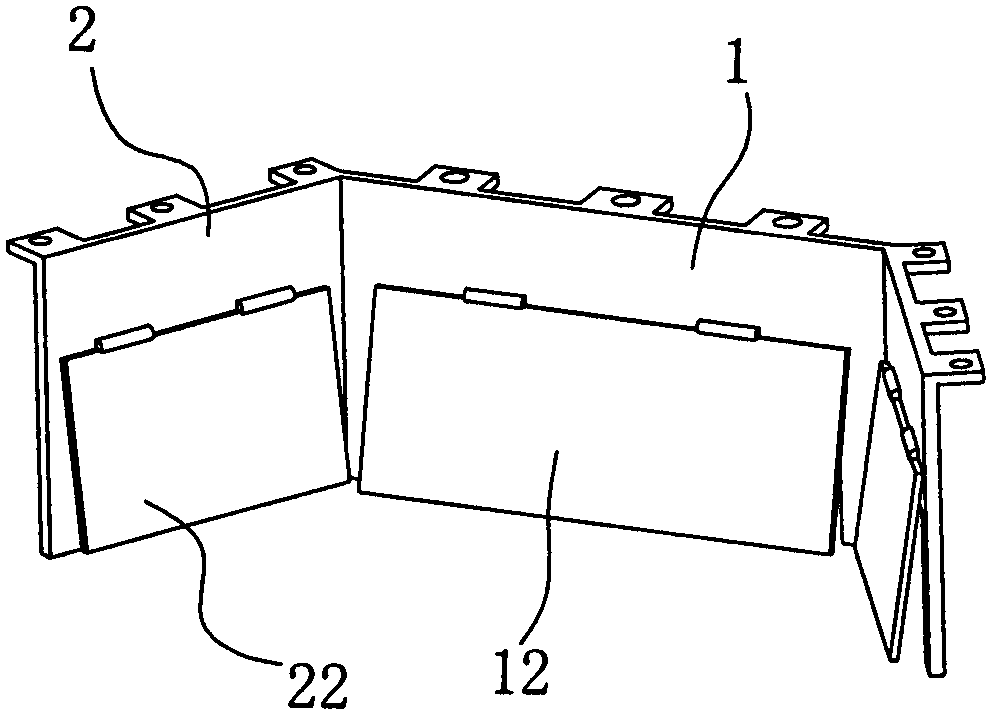

[0016] Such as figure 1 , figure 2 As shown, the grass baffle of the lawnmower of this embodiment includes a grass baffle body installed on the side of the mowing blade. The baffle 2, the front baffle 1 and the side baffle 2 have openings respectively, and the inside of the grass baffle body at the opening is respectively equipped with a front swing plate 12 and a side swing plate 22; the upper end of the front baffle 1 has a front The upper end of the mounting edge 11 and the side baffle 2 has a side mounting edge 21, and the front mounting edge 11 and the side mounting edge 21 are detachably fixedly connected to the frame by screws respectively.

[0017] The front swing plate 12 and the side swing plate 22 are respectively rotatably connected with the grass guard body through the hinge shaft 3, and the width of the front swing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com