water separator

A steam-water separator and hydrophobic technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of low droplet separation size of demister net pad, inability to effectively separate small droplets, long-term supply of steam-water separator Improve the efficiency of equipment separation, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

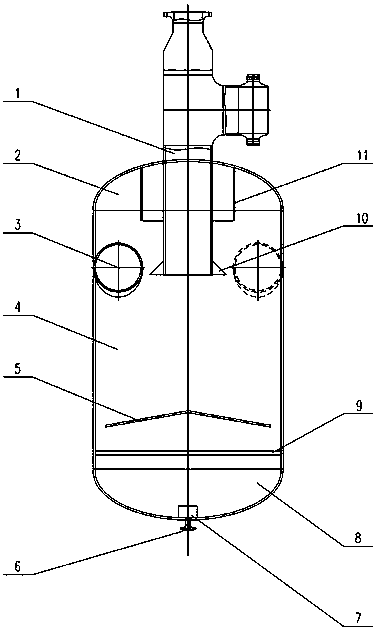

[0021] Such as figure 1 As shown, the steam-water separator described in this embodiment includes a steam exhaust pipe 1, an upper head 2, a steam inlet pipe 3, a cylinder body 4, a conical plate 5, a hydrophobic device 6, a vortex breaker 7, a lower seal Head 8, perforated plate 9, anti-liquid creep skirt 10 and cylindrical baffle 11.

[0022] The cylinder body 4 is welded with the upper head 2 and the lower head 8. There are two steam inlet pipes 3, which are installed on the upper part of the cylinder body 4 and arranged at an interval of 180°. Cut to set, and the steam inlet pipe 3 is inclined upward from the outside to the inside by 5°-15°, and the inclination angle is 10° as the best. Conical plate 5 and perforated plate 9 are installed on the lower part of cylinder body 4, steam exhaust pipe 1 and cylindrical baffle 11 are installed on the top of upper head 2, anti-liquid peristalsis skirt 10 is installed at the end of steam exhaust pipe 1, and lower head 8 Install hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com