A test tube operating system that is convenient for individual pick-and-place

A technology of operating system and test tube, applied in the direction of test tube holder/clamp, laboratory utensils, chemical instruments and methods, etc., can solve the problems of high cost, high technical cost, high risk, etc., achieve low cost, solve disinfection and sterilization resources , the effect of reducing experimental risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

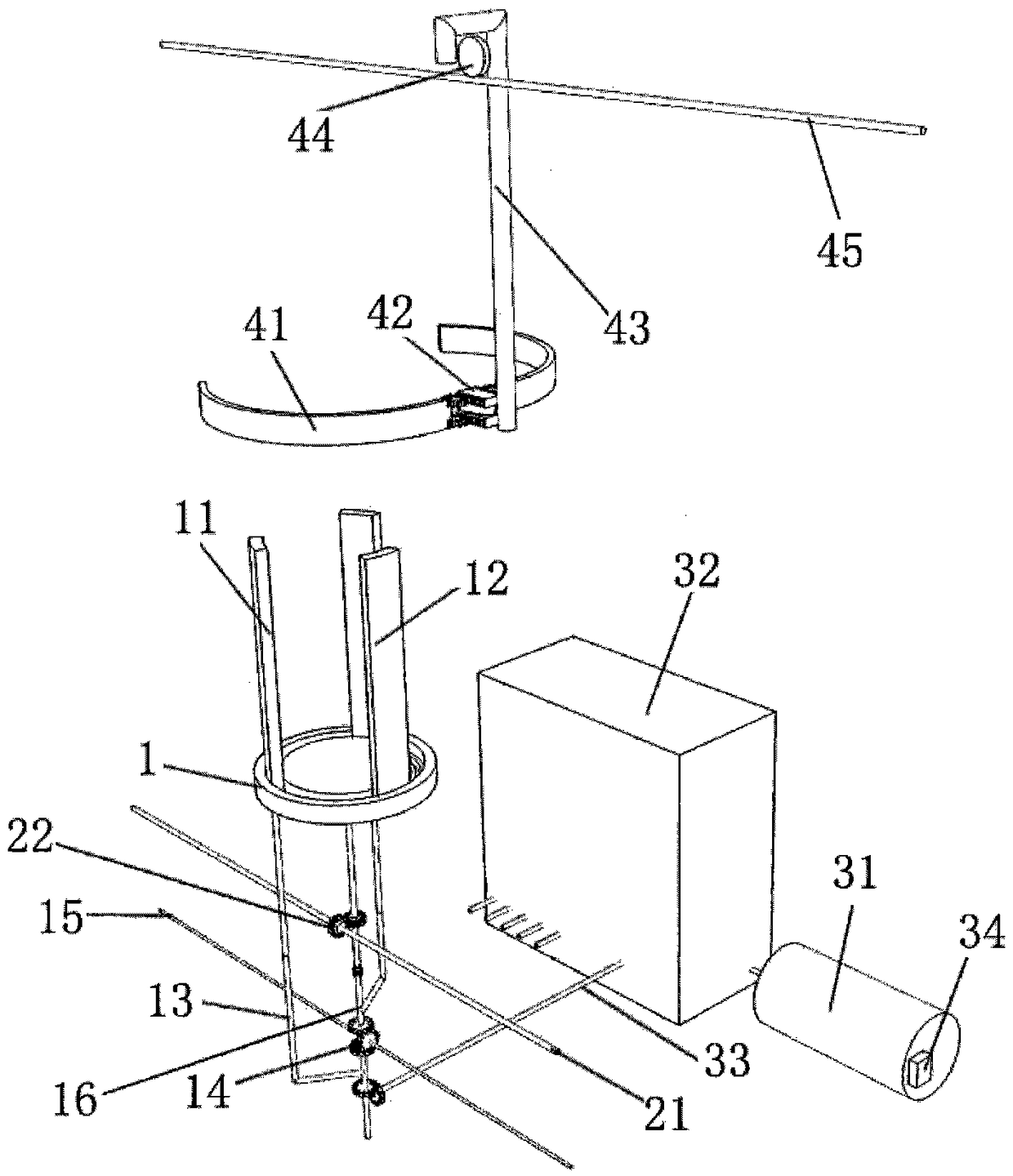

[0018] Such as figure 1 A test tube operating system that is convenient for individual pick-and-place shown includes a clamping device, a transmission device, and a leveling device; 34 is connected with the forward and reverse motor 31 circuits, the output shaft of the forward and reverse motor 31 is connected to drive the input shaft of the control box 32, the output shaft of the control box 32 is a transmission rod 33, and the far end of the transmission rod 33 has a gear structure and the clamping device The active rod 16 in the lower segment gear meshes; the active rod 16 in the clamping device is a three-stage structure of upper, middle and lower, the upper segment is a lead screw, and the screw nut of the lead screw is sleeved in the horizontal gear of the operation wheel group 22, and the lower segment rod A gear is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com