A flame retardant sample setting dryer

A dryer and flame retardant technology, applied in the field of flame retardant sample setting dryers, can solve the problems of difficult cleaning of rack guide rails, insufficient heating and setting, affecting the accuracy of samples, etc. Great effect, easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

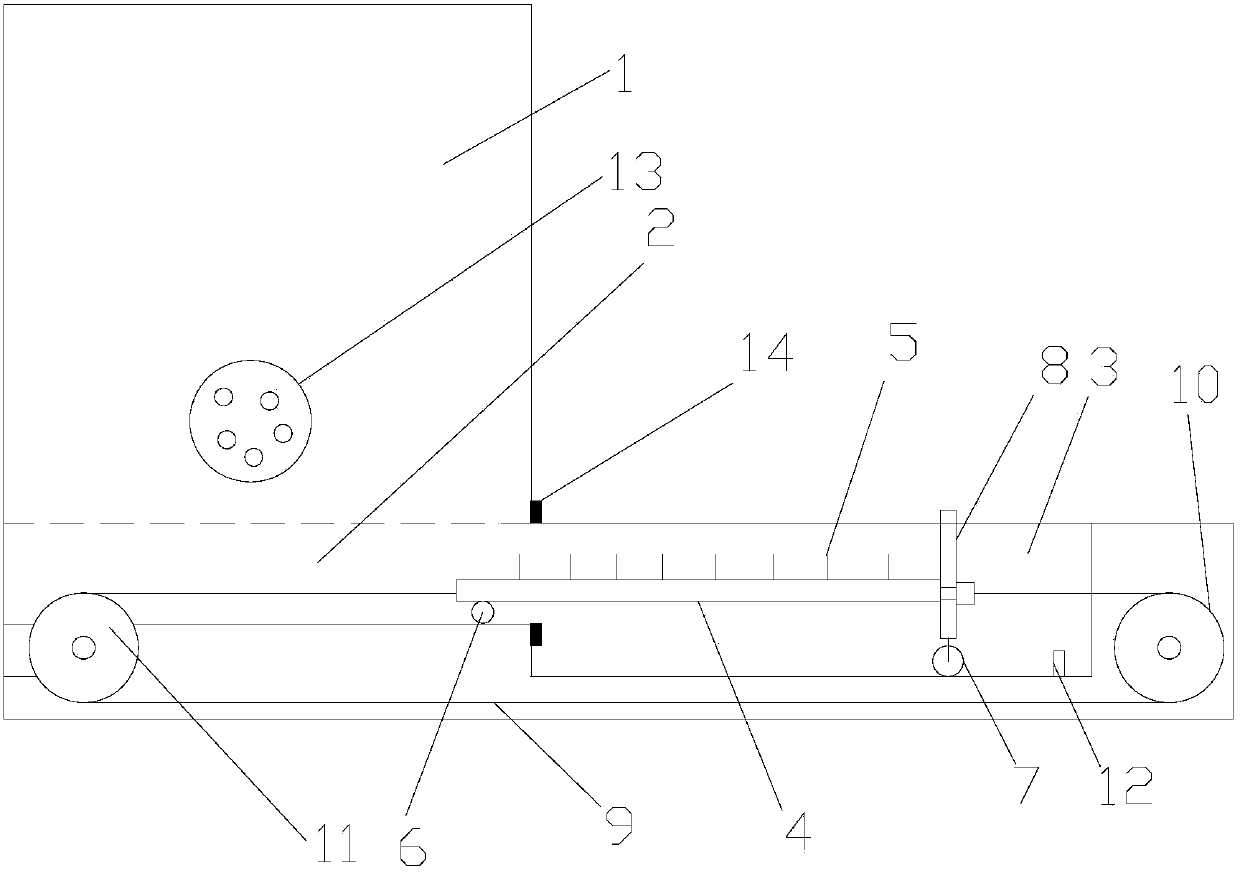

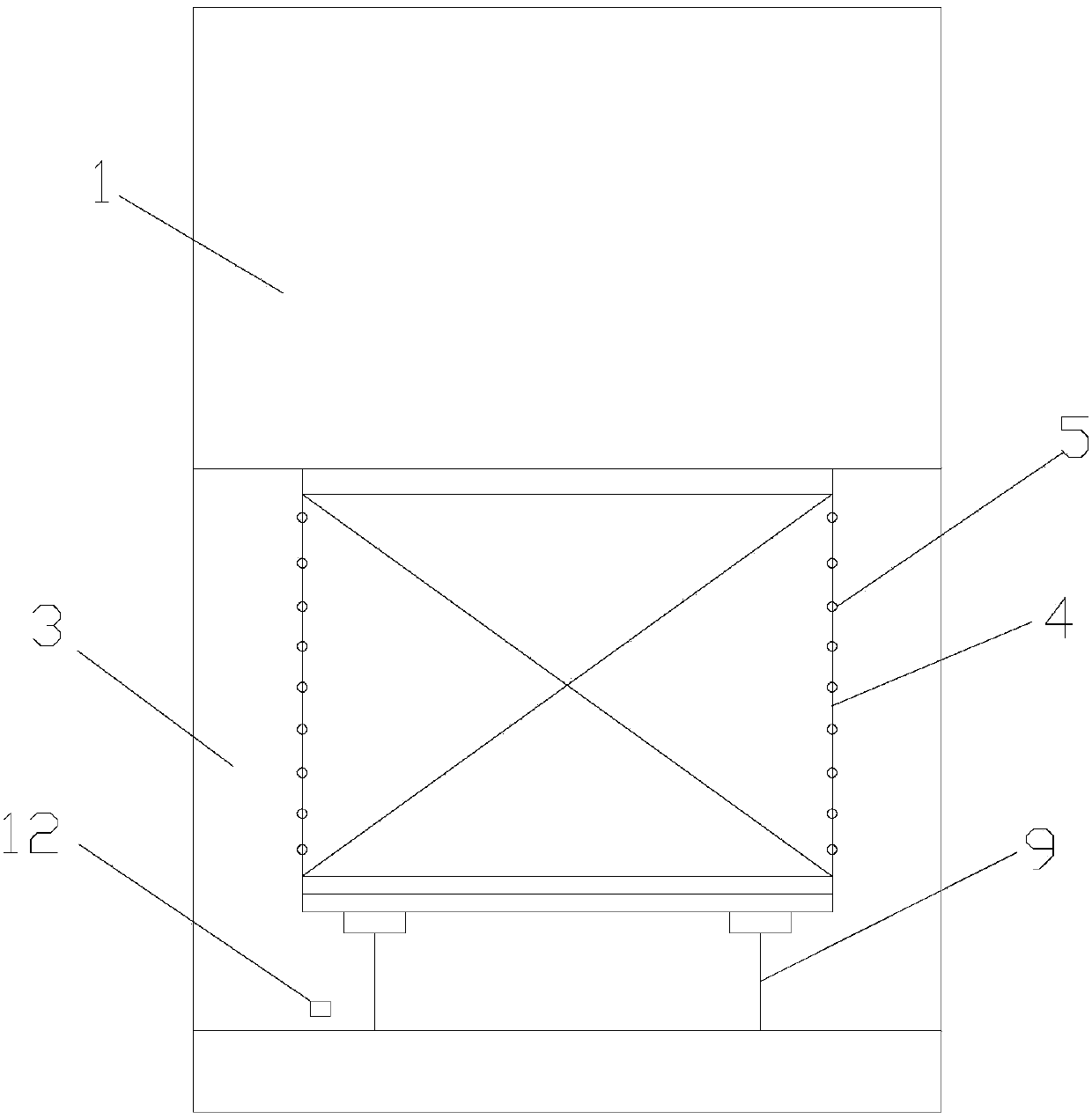

[0015] Example. A flame retardant sample setting dryer, constituted as follows figure 1 with 2 As shown, it includes a drying machine body 1, a drying channel 2 is provided at the lower part of the drying machine body 1, a sample placement tank 3 is provided at the side of the drying channel 2, a moving rack 4 is arranged in the sample placing tank 3, and the two sides of the moving rack 4 The side is provided with sample cloth fixing nails 5, the front end of the mobile frame 4 is set in the drying channel 2 through the front wheels 6, the rear end of the mobile frame 4 is set in the sample placement groove 3 through the rear wheels 7, the rear end of the mobile frame 4 A cover plate 8 is provided, and the end of the cover plate 8 is connected to the front end of the mobile frame 4 through a chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com