Pitched roof shunt mechanism

A shunting mechanism and inclined top technology, which is applied in the field of mold manufacturing for grille or one-mold multi-cavity products, can solve the problems of easy breakage of products, long distance of plastic convergence, and small convergence angle, so as to eliminate weld marks and save a lot of money. Cost, the effect of increasing product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

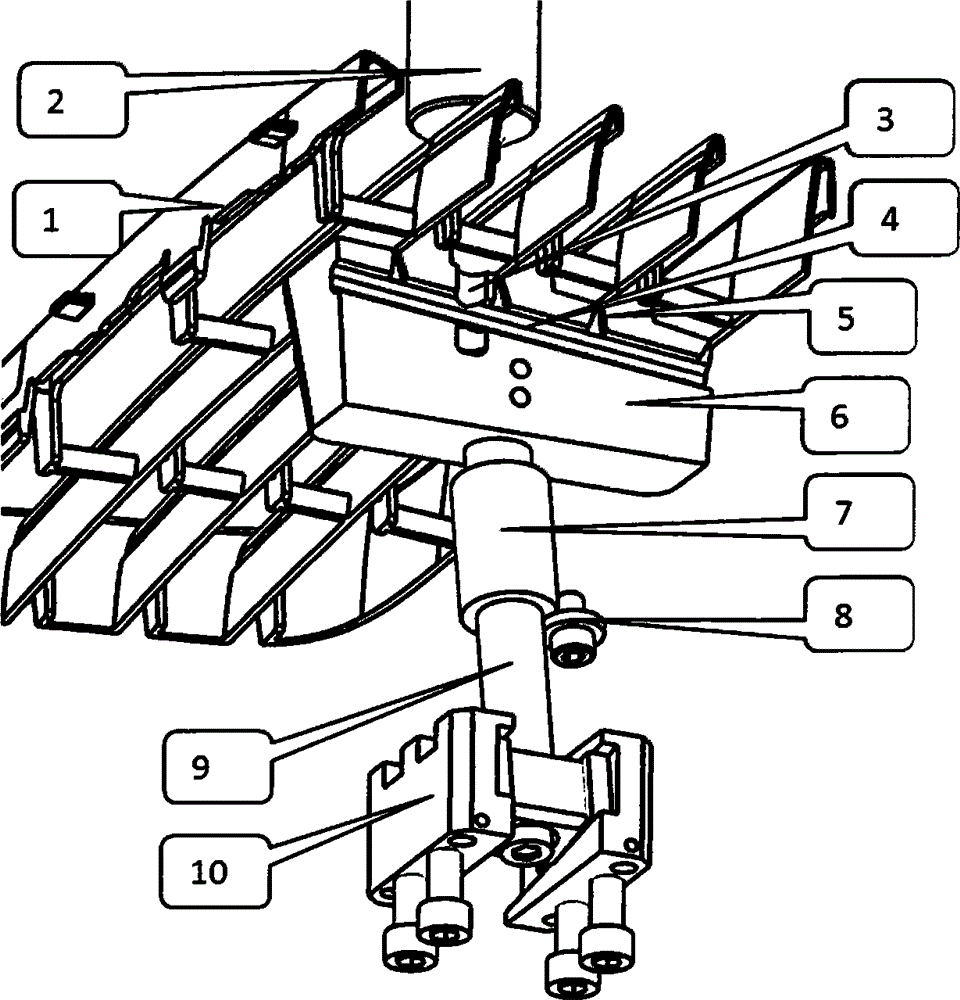

[0010] see figure 1 , product (1), hot runner nozzle (2), main gate (3), runner (4), glue inlet (5), inclined top block (6), inclined top copper sleeve (7), pressing block (8), inclined ejector pin (9), inclined top seat (10); the present invention is a kind of inclined ejector diverter mechanism, injection molding after mold closing, colloid is injected from hot runner nozzle 2, enters main rubber port (3), Then it enters the runner (4), and then enters the product (1) cavity through multiple glue inlets 5 on the inclined ejector block (6). 9) Under the promotion of the inclined top seat (10), the ejection movement is carried out along the specified track set by the inclined top copper sleeve (7) and the inclined top seat, and the inclined top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com