Intelligent express delivery, loading and unloading system

A technology of loading and unloading system and transportation system, applied in the field of mechanical transmission, can solve the problems of bloated structure, high transportation cost, poor express delivery quality, etc., and achieve the effect of saving energy, reducing transportation cost and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

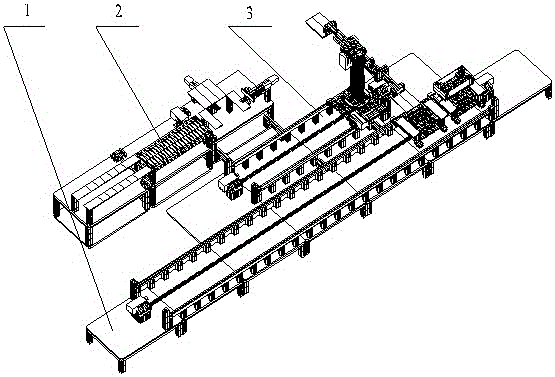

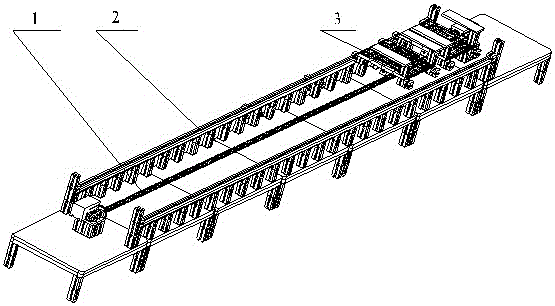

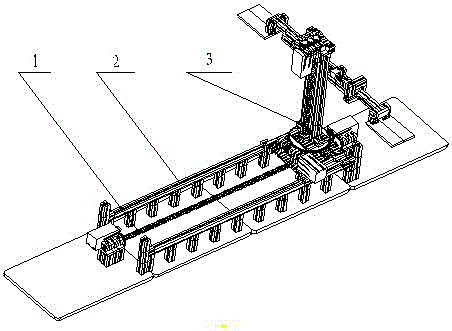

[0020] Further description will be given below in conjunction with the accompanying drawings and specific examples.

[0021] Build an express delivery intelligent loading and unloading system with the fischer model.

[0022] The automatic loading and unloading system is composed of a transmission track, a rotating base, and an automatic loading and unloading device. The two sides of the transmission track are parallel tracks, and a motor is placed at the beginning and end of the track to transmit the movement through the screw to make the automatic loading and unloading device and the goods on the track reach the same speed. When the carrier vehicle touches the switch, the automatic loading and unloading system will start. When the cargo loading and unloading is completed, the system will trigger the end switch, and the motor will reverse and return to the initial state. The rotating base is driven by a worm gear, and can reciprocate along the lead screw on the track and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com