An automatic supply system and supply method for segment connecting bolts

A technology of connecting bolts and automatic supply, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of low mechanization of transportation of segment connecting bolts, achieve improved assembly efficiency, good integration, and high promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

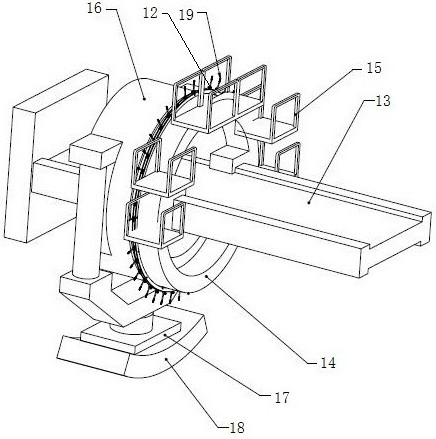

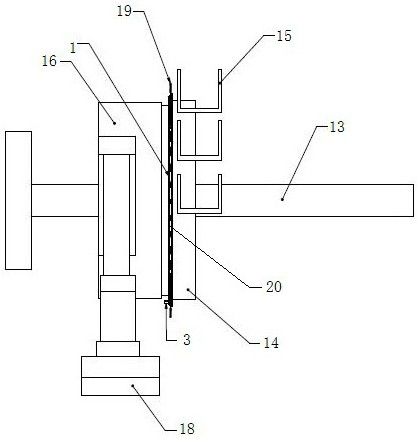

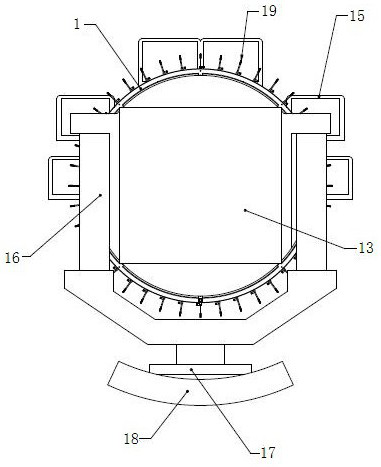

[0045] Embodiment 3: A shield machine, including the automatic supply system for the segment connecting bolts described in Embodiment 2, the ring support 1 of the automatic supply system for the segment connecting bolts is fixed on the moving part of the segment assembly machine On the frame 14, between the slewing frame 16 and the mobile frame 14, and on one side of the working platform 15 of the assembly machine, it is convenient for the personnel on the working platform to quickly take the segment connecting bolts. The central axis of the ring support 1 coincides with the central axis of the shield body of the shield machine to ensure that the automatic supply system can smoothly and efficiently transport the segment connecting bolts to the designated position. The segment assembly machine is located on the main beam 13, and other structures and Existing shields are the same or similar, such as Figure 1~3 shown.

Embodiment 4

[0046] Embodiment 4: A supply method of the automatic supply system of the segment connecting bolts for the shield machine as described in Embodiment 2 or 3, the steps are as follows:

[0047] S1: Fix the ring support 1 of the automatic supply system for the connecting bolts of the segment on the moving frame 14 of the segment assembly machine, and between the rotary frame 16 and the moving frame 14, to ensure the central axis of the ring support 1 It is collinear with the central axis of the shield body of the shield machine, which is convenient for quick access to the segment connecting bolts clamped by the bolt clamping mechanism when the segments are connected;

[0048] S2: Manually install the segment connecting bolts 19 into the bolt clamping mechanism 12 evenly distributed on the slewing ring 20, and the bolt clamping mechanism 12 clamps the segment connecting bolts 19 one-to-one, that is, a bolt clamping mechanism A segment connecting bolt is clamped, and the segment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com