A kind of preparation method and preparation device of energy storage board

The technology of shell plate and plate material is applied in the field of preparation method of energy storage plate and preparation device thereof, and can solve the problems of reducing the production efficiency of energy storage plate, narrow space of energy storage plate, viscous texture of energy storage agent, etc. The effect of slow flow, improved cooling efficiency, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

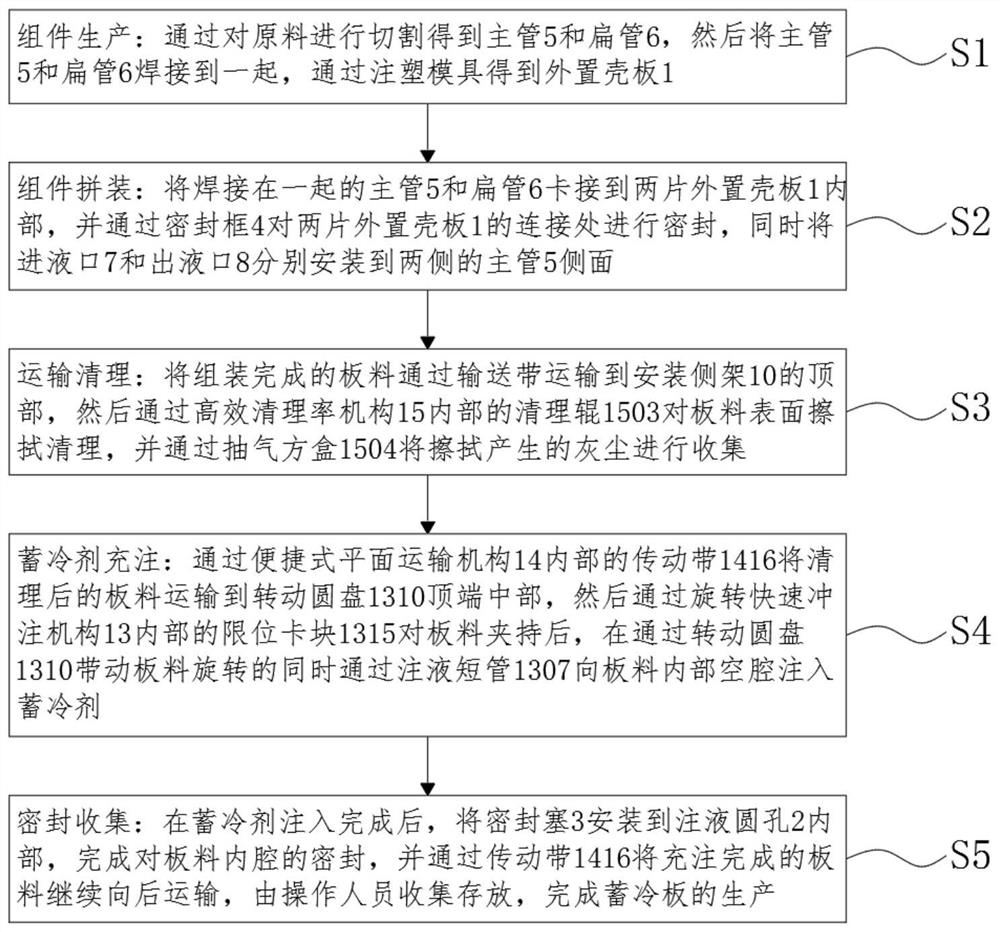

[0057] This embodiment takes cold storage as an example (when the heat storage agent is filled in the energy storage plate, it is the heat storage plate, and the principles of the two are the same), and the technical solution of the present invention is described: figure 1 As shown, the present invention provides a technical solution, a preparation method of a cold storage plate, comprising the following steps;

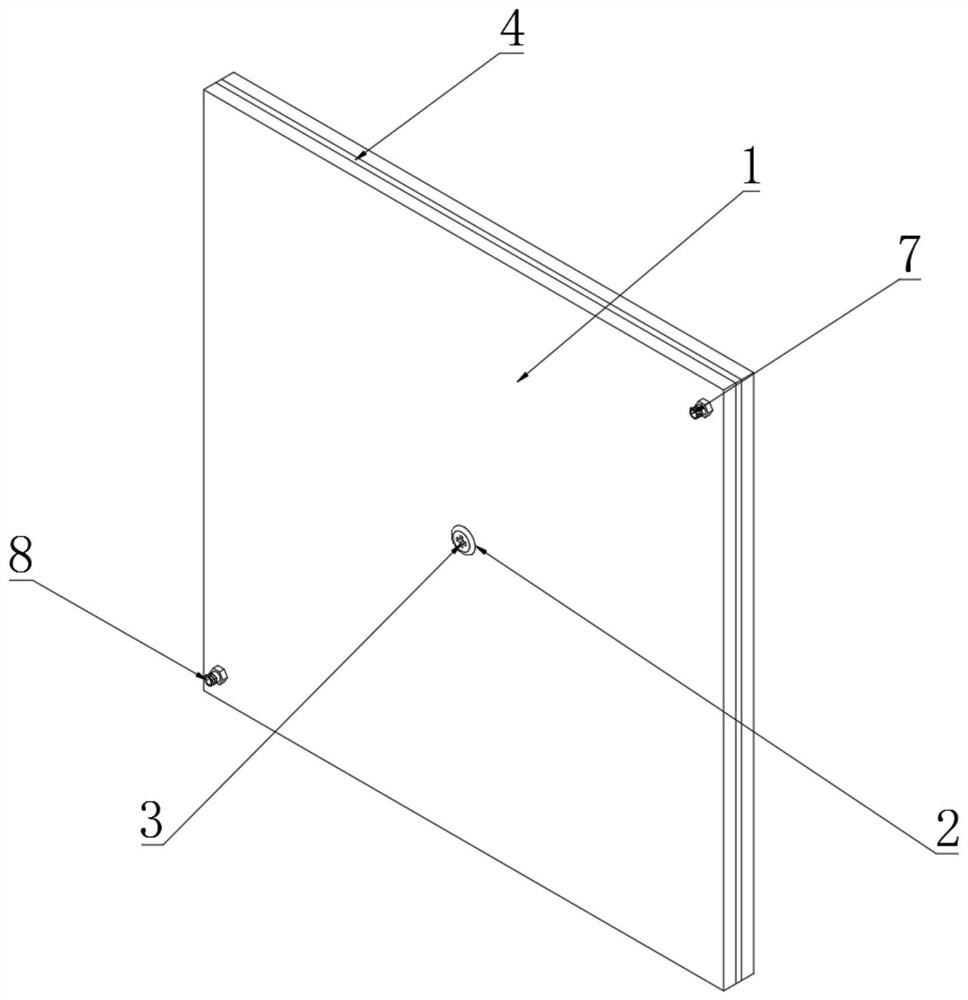

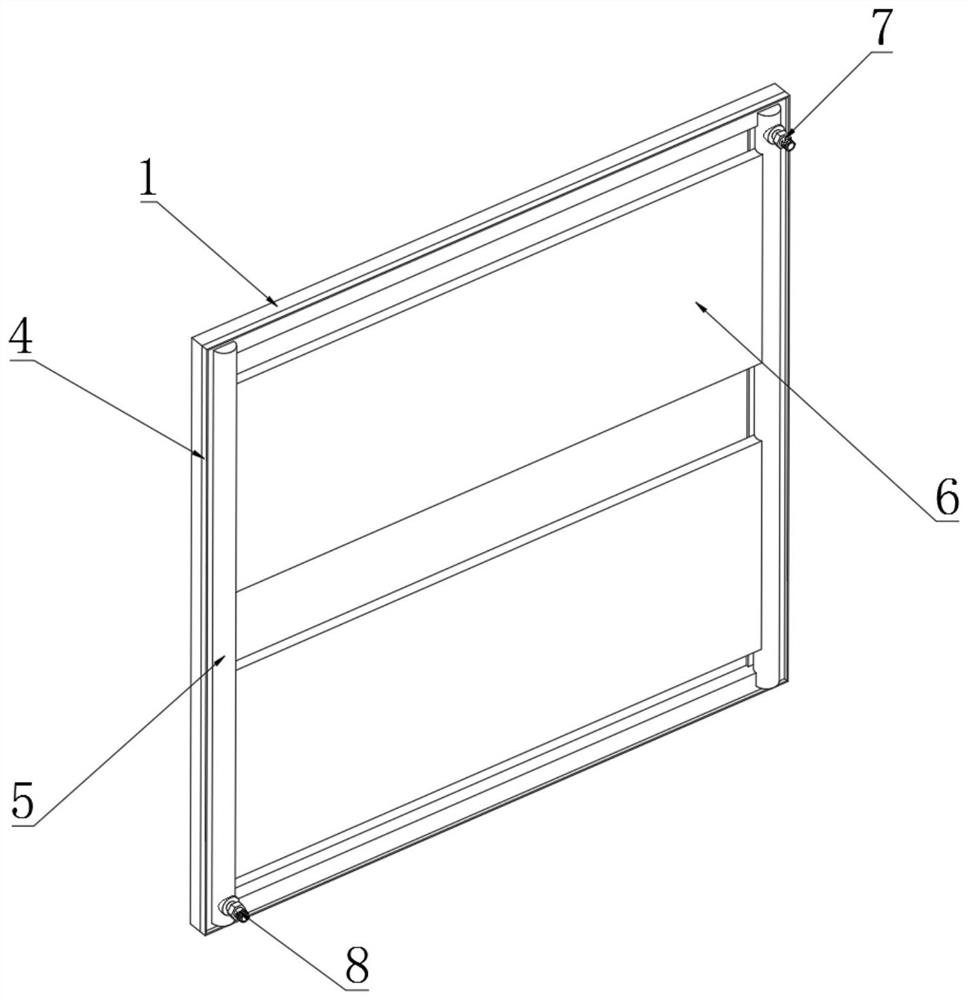

[0058] S1. Component production: The main pipe 5 and the flat pipe 6 are obtained by cutting the raw material, and then the main pipe 5 and the flat pipe 6 are welded together, and the outer shell plate 1 is obtained by an injection mold;

[0059] S2. Assembly of compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com