Dissolved air flotation contact chamber

A technology of dissolved air flotation and contact chamber, which is applied in the field of air flotation system, can solve the problems that the space of the separation chamber cannot reduce the separation time, the contact between dissolved air water and sewage is insufficient, and the utilization rate of microbubbles is affected, so as to save materials The effect of increasing the chance of contact with the occupied area and reducing the floating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

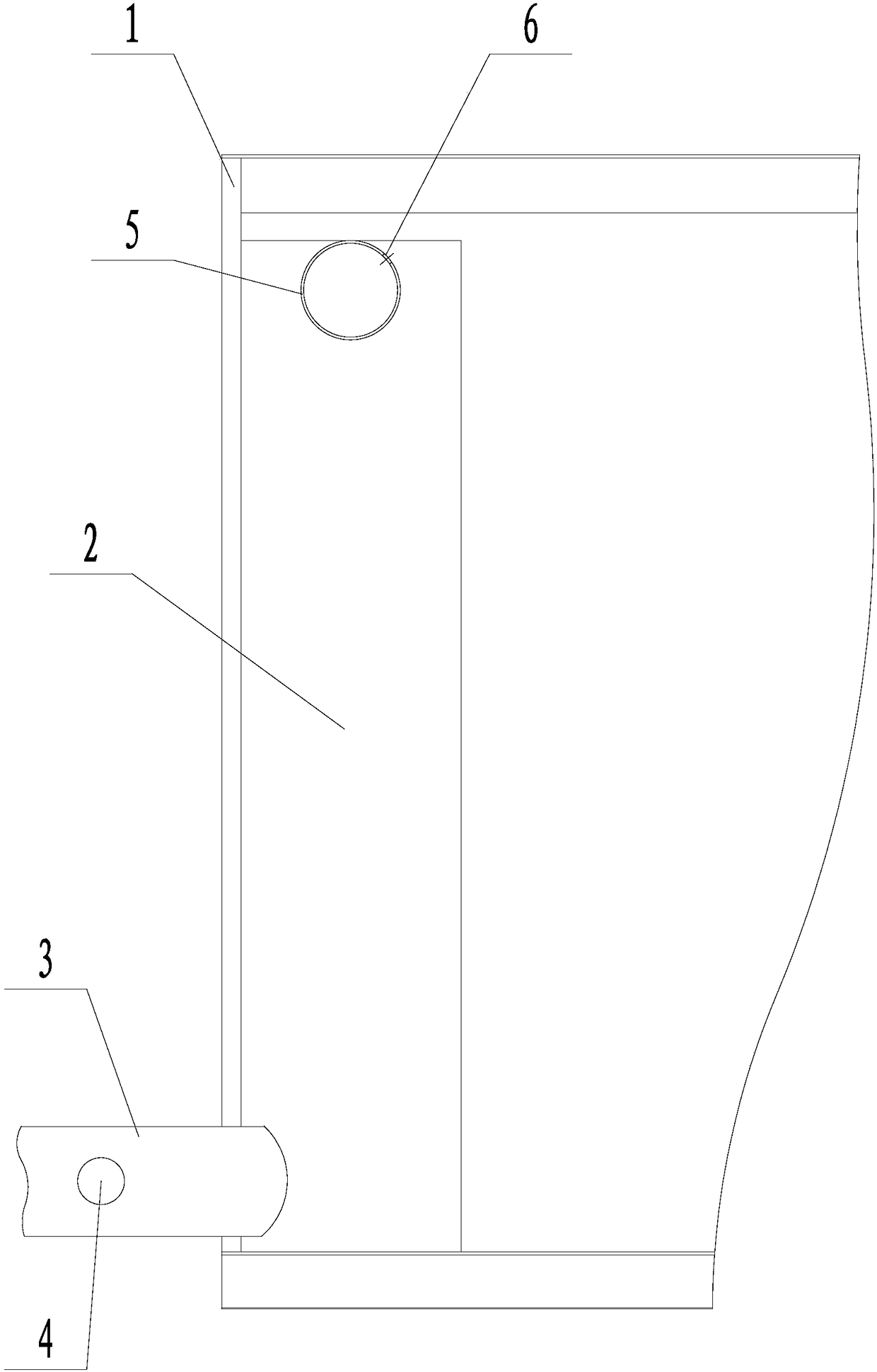

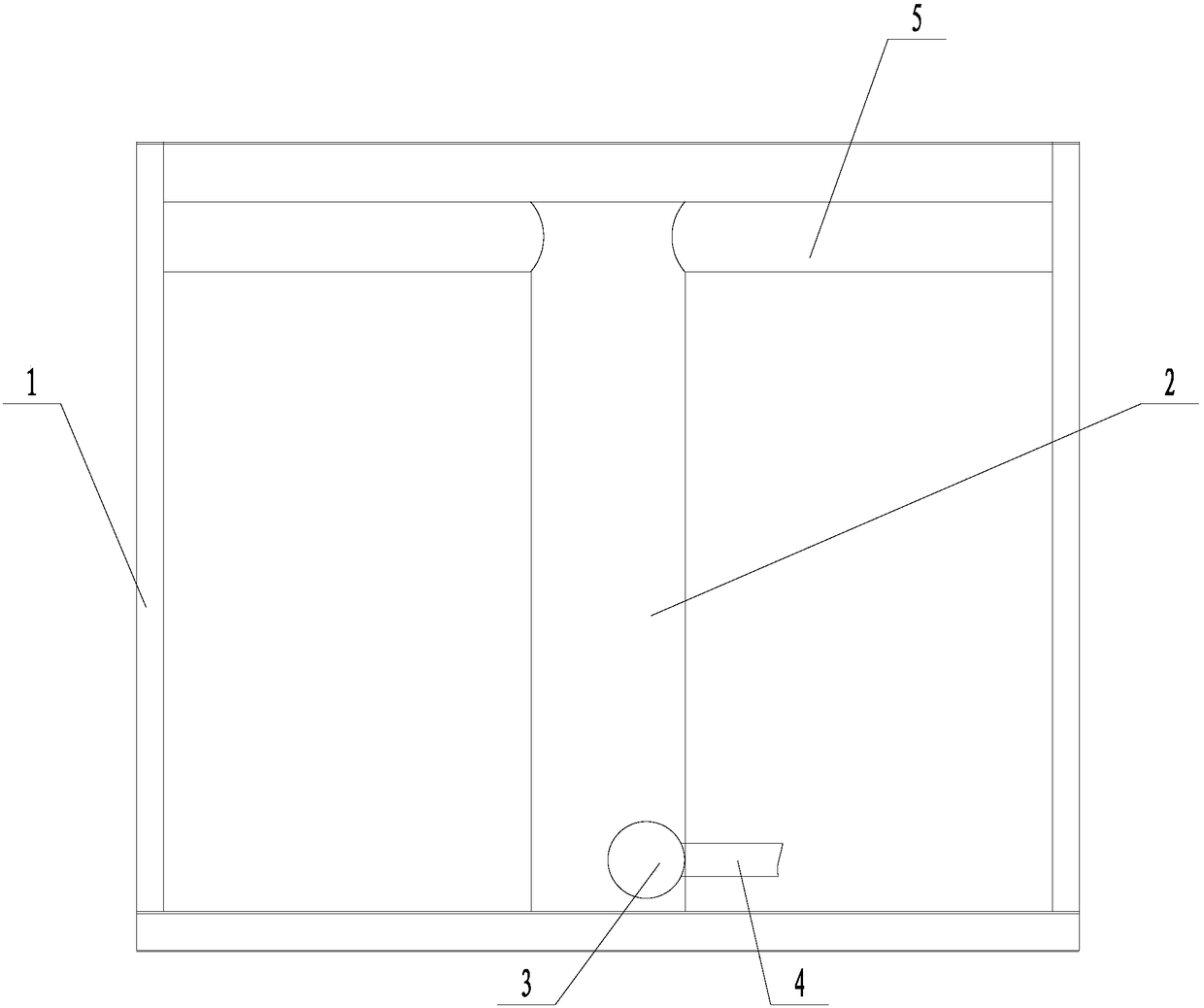

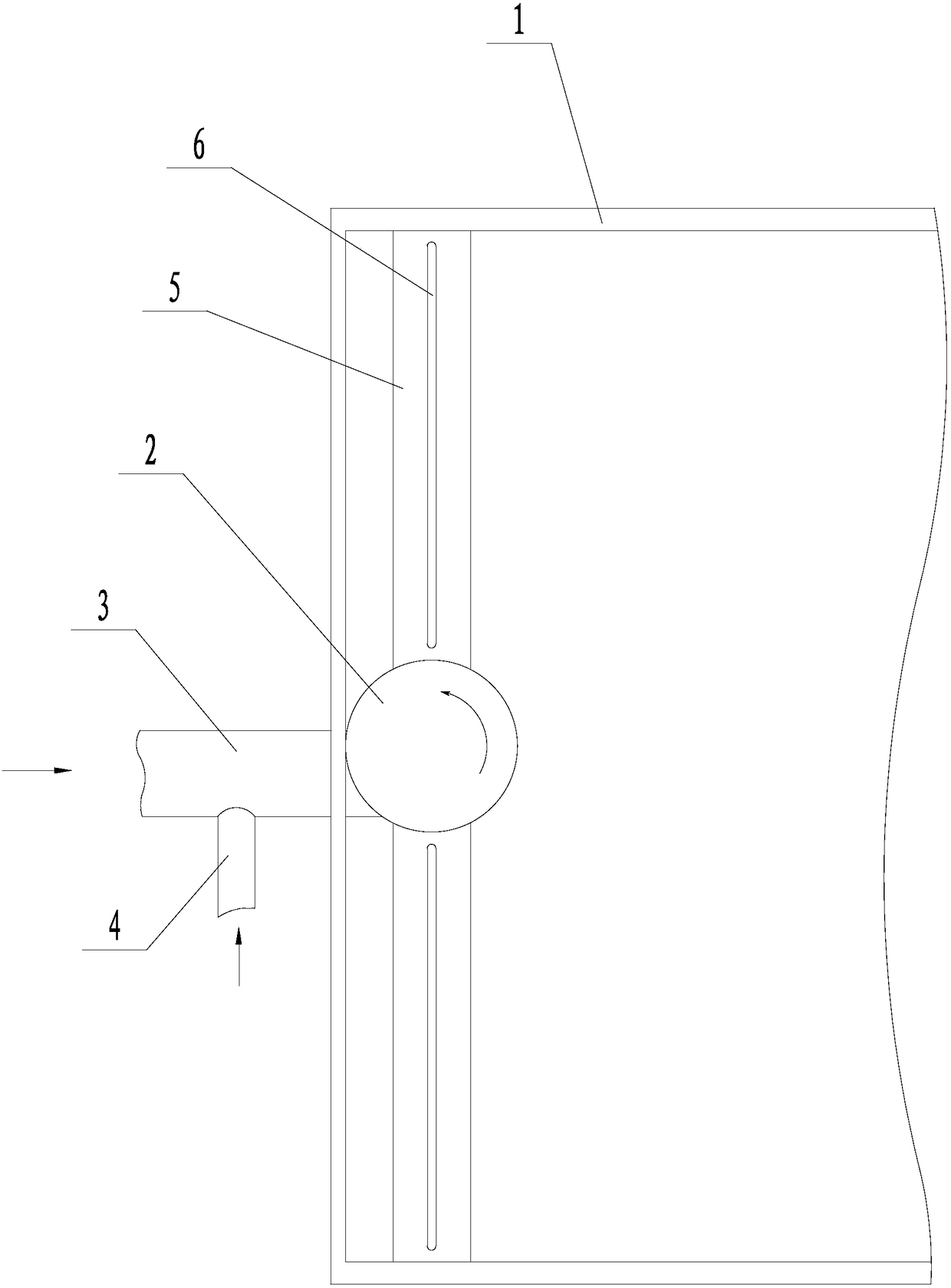

[0023] Embodiment 1: a kind of dissolved air flotation contact chamber (see attached Figures 1 to 3 ), including an air flotation tank 1, and an air pollution contact tank 2 vertically arranged in the air flotation tank close to the side wall. The air pollution contact tank has a cylindrical structure. A sewage water inlet pipe 3 is connected tangentially to the side wall of the lower end of the gas-pollution contact tank, and a dissolved air water inlet pipe 4 is connected to the sewage water inlet pipe. The upper end of the gas pollution contact tank is connected with a distribution pipe 5 arranged horizontally. There are two distribution pipes. The two distribution pipes are symmetrically arranged on both sides of the gas pollution contact tank. An elongated release port 6 is provided on the outer wall of the distribution pipe along the length direction. One or more release ports are arranged on each distribution pipe. Diameter of air pollution contact tank > diameter of...

Embodiment 2

[0025] Embodiment 2: a kind of dissolved air flotation contact chamber (see attached Figure 4 , attached Figure 5 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a cleaning port 7 is provided on the side wall of the lower end of the air pollution contact tank, the cleaning port penetrates to the outer wall of the air flotation tank, and the position of the cleaning port on the outer wall of the air flotation tank is sealed A closing plug 8 is attached. The outer end of the distribution pipe is connected to the side wall of the air flotation tank, the inside of the distribution pipe close to the outer end is sealed and connected with a push plug 9, the outer end of the distribution pipe is connected with a limit sleeve 10 for limiting the push plug, and the push plug is connected with a positioning sleeve 11. The outer end of the positioning sleeve is provided with an extension strip 12, and the positioning sleeve is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com