Method for extracting isobutane, isobutene and hydrogen rich gas from chemical tail gas

A technology of isobutane isobutene, chemical tail gas, applied in chemical instruments and methods, hydrogen separation, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, extracting isobutane isobutene and hydrogen-rich gas from chemical tail gas

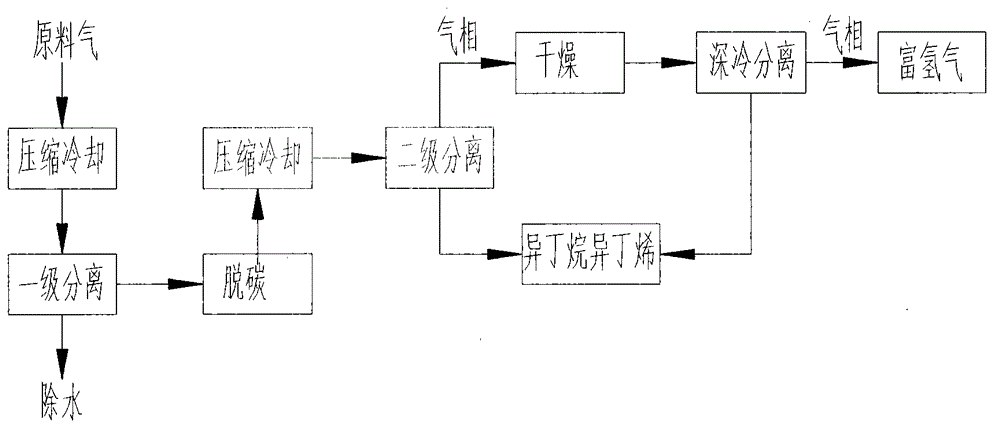

[0025] The main components of raw material gas are isobutane 41% (m%), isobutene 24% (m%), water 31% (m%), and also contain a small amount of CH4, C2H6, C3H8, H 2 and CO 2 . Such as figure 1 As shown, the method of the present embodiment is as follows:

[0026] 1) First-stage gas-liquid separation: After the raw material gas is compressed and cooled, the temperature is 40°C and the pressure is 0.5MPa, and it enters the first-stage gas-liquid separation tank for raw material gas, and the liquid phase and gas phase are obtained by gas-liquid separation. The water in the raw material gas The system is separated in a liquid state. After testing, the water does not contain isobutane and isobutene, and the water content in the gas phase is 1.5% (m%).

[0027] 2) Decarburization: Step 1) The gas phase generated by gas-liquid separation then enters the decarburization process, using ...

Embodiment 2

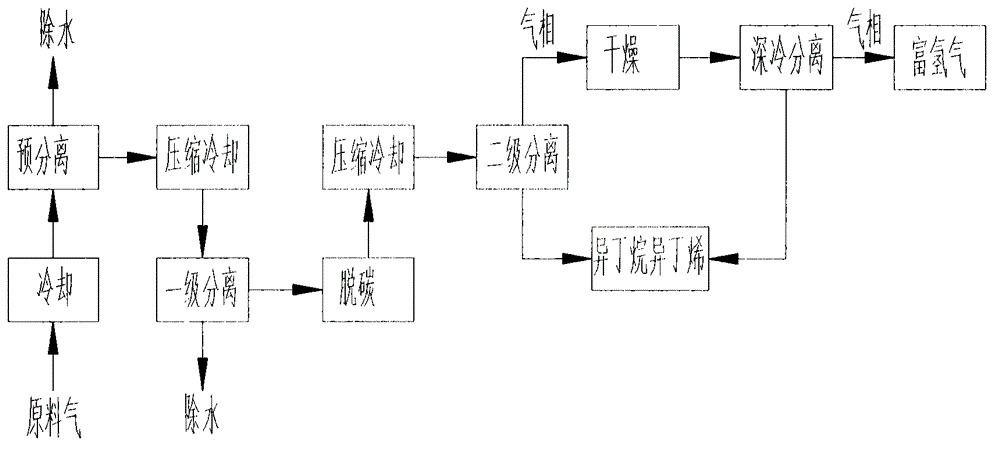

[0031] Example 2, Extracting isobutane isobutene and hydrogen-rich gas from chemical tail gas

[0032] The difference between embodiment 2 and embodiment 1 is:

[0033] The main components of the feed gas are isobutane 44% (m%), isobutene 17% (m%), water 37% (m%), and a small amount of H 2 , CO 2 . The raw material gas is cooled from 97°C to 40°C, and then enters the pre-separator (gas-liquid separator) for gas-liquid separation, reducing the water content to 4% (m%), and then enters the Raw gas primary separation tank. The schematic diagram of the process is as figure 2 shown.

[0034] In this embodiment, the main components of the liquid phase separated from the liquid phase obtained by the second-stage gas-liquid separation are isobutane and isobutene, while containing a small amount of water, and sent to the product storage tank.

[0035] In the third-stage gas-liquid separation tank, hydrogen-rich gas with a purity of 96% is obtained at the top of the tank, and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com