Oil-accumulating oil-absorbing vessel

An oil-absorbing ship and oil-gathering technology, which is applied in the direction of hull, shipbuilding, hull design, etc., can solve the problems of damaging the water environment, not being environmentally friendly, and not being able to adapt to thin-layer oil slicks, etc., to achieve high treatment efficiency, high oil absorption efficiency, and increased The effect of oil residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

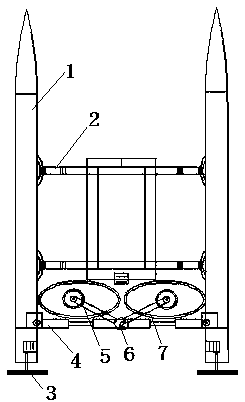

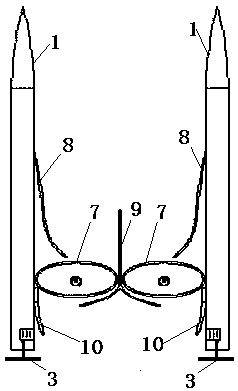

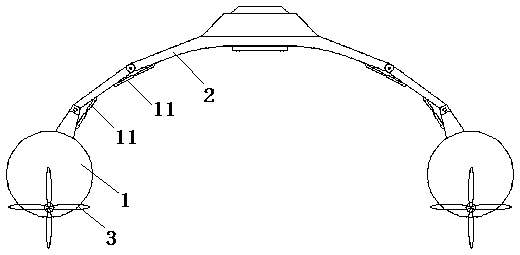

[0034] like figure 1 Shown, a kind of oil-gathering type oil-absorbing ship comprises hull and is located on the oil-absorbing device 7 on hull, as Figure 5 As shown, the oil suction device 7 includes an oil suction cover 12 with the opening facing downwards. The bottom edge of the oil suction cover 12 can generate negative pressure. motor 14) and suction nozzle 17 (the suction nozzle 17 is connected to the oil storage mechanism through the suction pipe 16 through the oil suction cover 12, and the suction pipe 16 is set near the rotating shaft 15), the suction nozzle 17 inlet is downward and is located on the spiral blade 26 ( Three groups of suction nozzles 17 and suction pipes 16 are arranged above the rotating blade 18). During operation, the bottom of the oil suction cover 12 is higher than the liquid surface, the inlet of the suction nozzle 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com